Preparation method of GO-WO3/TiO2 microsphere film electrode

A thin-film electrode and microsphere technology, which is applied in the field of preparation of GO-WO3/TiO2 microsphere thin-film electrodes, can solve the problems of strict reaction conditions, low film-making efficiency, small comparative area, etc., and achieves simple and good experimental reagents. Experimental application value, the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

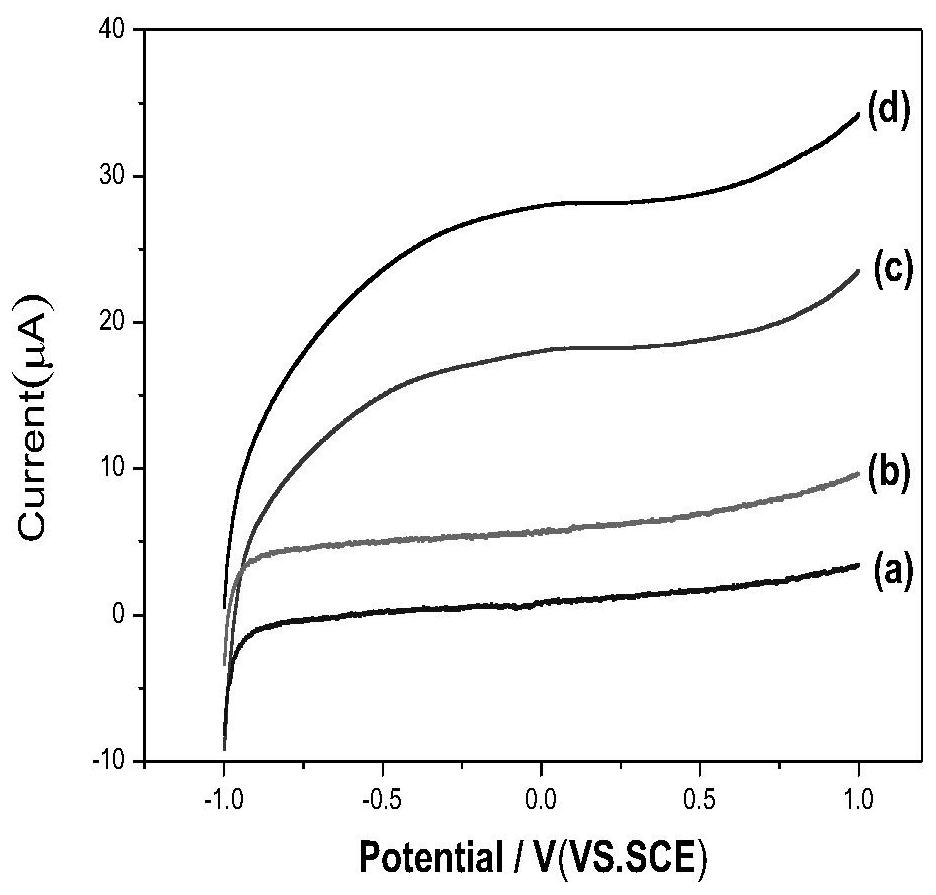

Embodiment 1

[0038] (1) Cleaning of the ITO conductive glass: Wash the ITO conductive glass with detergent, acetone, anhydrous ethanol and deionized water in sequence for 15 minutes, and then dry it naturally.

[0039] (2) The clean ITO conductive glass is placed in a 0.02 mol / L hydrochloric acid solution for etching for 30 minutes, then dried and used for later use.

[0040] (3) Accurately weigh 0.08g of graphene-WO 3 / TiO 2 The powder is placed in a mortar, and 3 to 4 drops of NMP are added to fully grind it uniformly, and then 0.02 g of polyvinylidene fluoride (PVDF) is added to grind it uniformly to form a uniformly dispersed slurry.

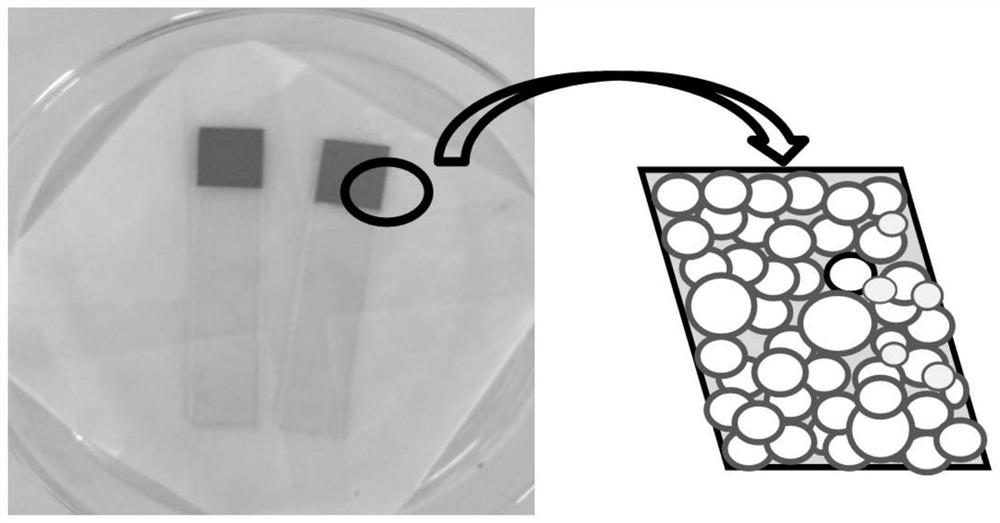

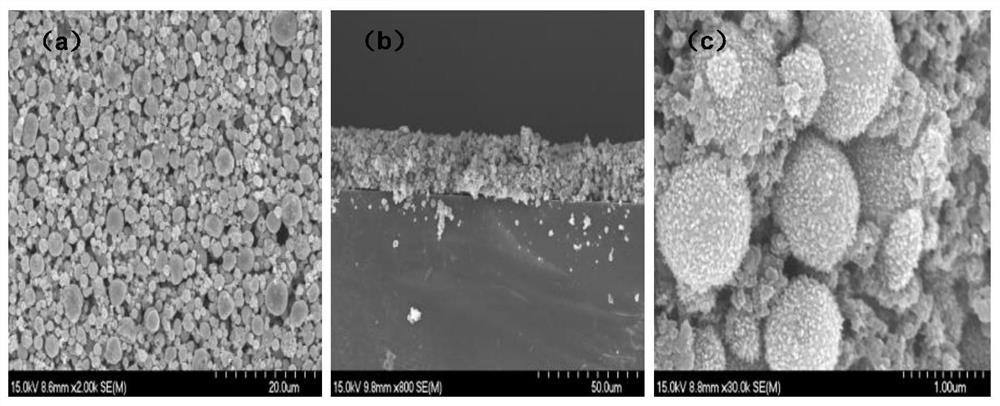

[0041] (4) Preparation of graphene-WO by blade coating method 3 / TiO 2 For thin film electrodes, the coated electrodes were first dried naturally at room temperature; then, they were placed in a muffle furnace and heated to 200 °C at 1 °C / min, and then kept for 2 h to obtain spherical graphene-WO. 3 / TiO 2 Thin film electrodes.

[0042] Preparation...

Embodiment 2

[0045] (1) Same as step (1) in Example 1.

[0046] (2) The clean ITO conductive glass is placed in a 0.01 mol / L hydrochloric acid solution for etching for 10 minutes, then dried and used for later use.

[0047] (3) Same as step (3) in Example 1.

[0048] (4) Same as step (4) in Example 1.

[0049] The prepared graphene-WO 3 / TiO 2 Microsphere thin film electrode, the film surface is made of graphene-WO 3 / TiO 2 The microspheres are piled up. There are many holes on the surface of the film, but it still maintains a complete spherical shape. There is no crack or crack on the surface of the film. The thickness of the film electrode is relatively uniform, about 15-25 μm.

Embodiment 3

[0051] (1) Same as step (1) in Example 1.

[0052] (2) The clean ITO conductive glass is placed in a 0.01 mol / L acetic acid solution for etching for 10 minutes, then dried and used for later use.

[0053] (3) Same as step (3) in Example 1.

[0054] (4) Same as step (4) in Example 1.

[0055] The prepared graphene-WO 3 / TiO 2 Microsphere thin film electrode, the film surface is made of graphene-WO 3 / TiO 2 The microspheres are piled up. There are many holes on the surface of the film, but it still maintains a complete spherical shape. There is no crack or crack on the surface of the film. The thickness of the film electrode is relatively uniform, about 15-25 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com