Composite carbon microspheres as well as preparation method and application thereof

A composite carbon and microsphere technology, applied in chemical instruments and methods, carbon preparation/purification, carbon compounds, etc., can solve the problems of unable to maintain the spherical structure of starch granules, not suitable for large-scale production, and existing safety problems, etc., to achieve Improve the first Coulombic efficiency and high-current charge-discharge performance, avoid fusion and foaming, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of composite carbon microspheres, comprising the following steps:

[0033] A) graphene oxide dispersion is mixed with starch to obtain mixed solution;

[0034] B) spray-drying the mixed solution;

[0035] C) process the product after step B) at 200~260 ℃;

[0036] D) Under the condition of protective gas, the product processed in step C) is heated to 800-1500°C at a rate of 0.5-5°C / min, and carbonized at high temperature at 800-1500°C to obtain composite carbon microspheres.

[0037] In the present invention, the graphene oxide dispersion liquid and starch are first mixed to obtain a mixed liquid.

[0038] In some embodiments of the present invention, the number of layers of the graphene oxide is 1-5 layers, and the diameter of the lamellae is 5-20 μm.

[0039] In some embodiments of the present invention, the concentration of the graphene oxide dispersion is 1-10 mg / mL. In certain embodiments, the concentration of the gra...

Embodiment 1

[0068] 1) 500 mL of graphene oxide dispersion (concentration is 2 mg / mL, and the solvent is deionized water) and 100 g of potato starch are added to the mixer, stirred for 1 h, and fully mixed to obtain a mixed solution;

[0069] 2) setting the drying temperature of the spray dryer to be 250°C, atomization frequency 350Hz, and using the peristaltic pump to suck the obtained mixed solution into the spray dryer for drying at a feed rate of 60mL / min;

[0070] 3) The sample obtained in step 2) was treated in a muffle furnace at 230°C for 6h;

[0071] 4) Place the processed sample in step 3) in a high-temperature carbonization furnace, raise the temperature to 1400°C at a heating rate of 3°C / min in a nitrogen atmosphere, carbonize at high temperature for 2 hours, naturally cool to room temperature, and take it out to obtain graphene Graphene-coated starch-based carbon microspheres with a coating amount of 0.5 wt%.

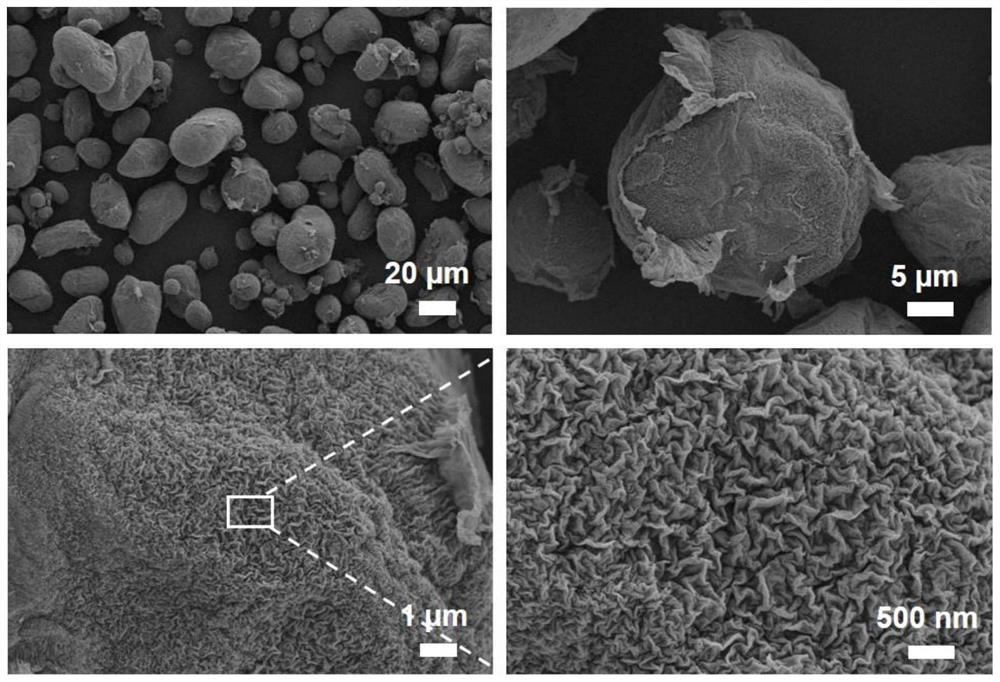

[0072] figure 1 The SEM image of the graphene-coated starch-base...

Embodiment 2

[0079] 1) 500 mL of graphene oxide dispersion (concentration is 2 mg / mL, and the solvent is deionized water) and 20 g of potato starch are added to the mixer, stirred for 1 h, and fully mixed to obtain a mixed solution;

[0080] 2) setting the drying temperature of the spray dryer to be 250°C, atomization frequency 350Hz, and using the peristaltic pump to suck the obtained mixed solution into the spray dryer for drying at a feed rate of 60mL / min;

[0081] 3) The sample obtained in step 2) was treated in a muffle furnace at 230°C for 6h;

[0082] 4) Place the processed sample in step 3) in a high-temperature carbonization furnace, raise the temperature to 1400°C at a heating rate of 3°C / min in a nitrogen atmosphere, carbonize at high temperature for 2 hours, naturally cool to room temperature, and take it out to obtain graphene Graphene-coated starch-based carbon microspheres with a coating amount of 2.5 wt%.

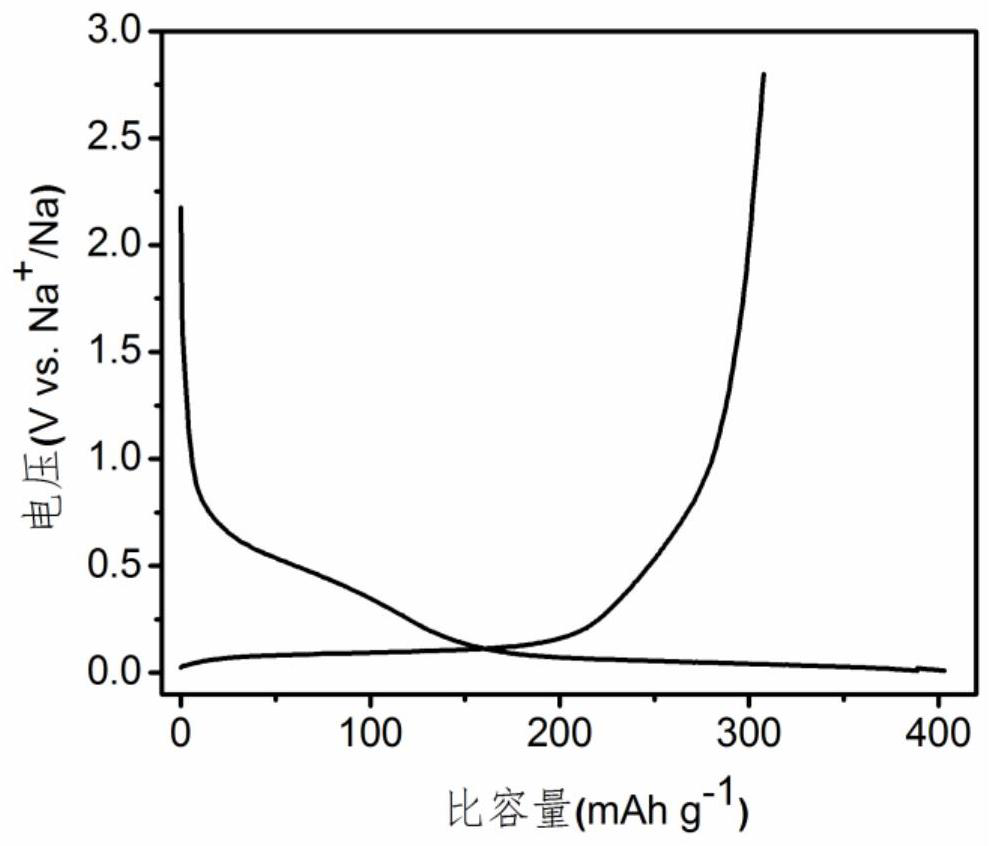

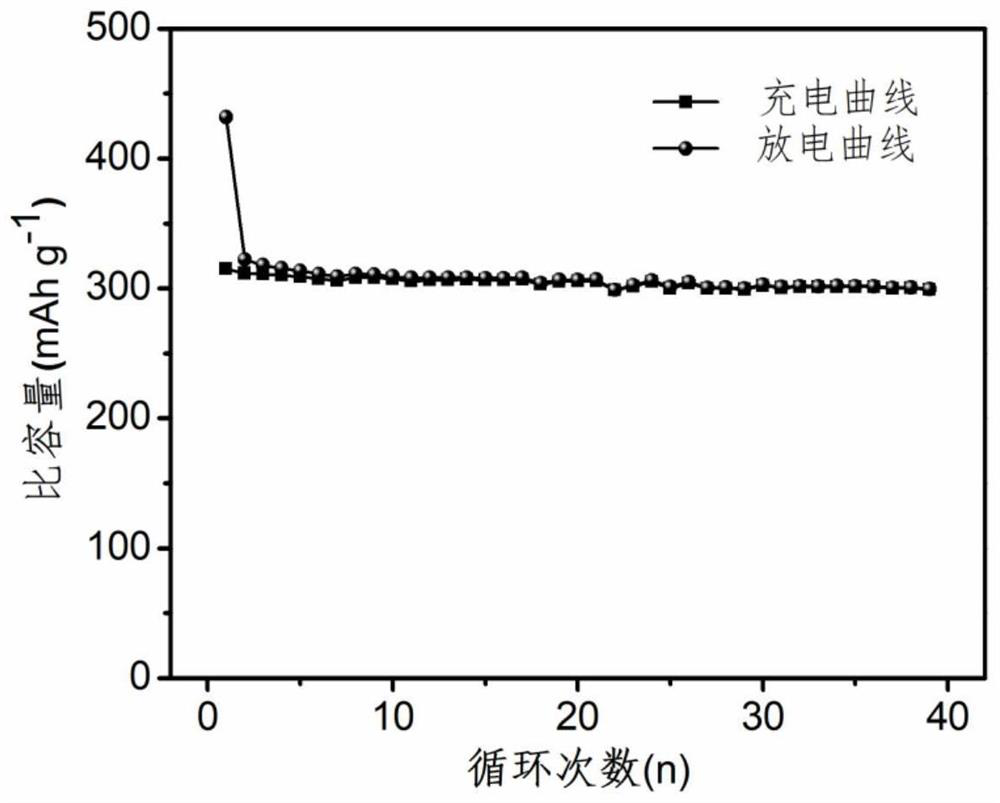

[0083]The obtained graphene-coated starch-based carbon microsphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com