Method for preparing magnetic carbonized resin microspheres

A technology of resin microspheres and carbonized resins, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve problems such as unsatisfactory effects and residues, and achieve high mechanical strength, strong impact resistance, and strong adsorption. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

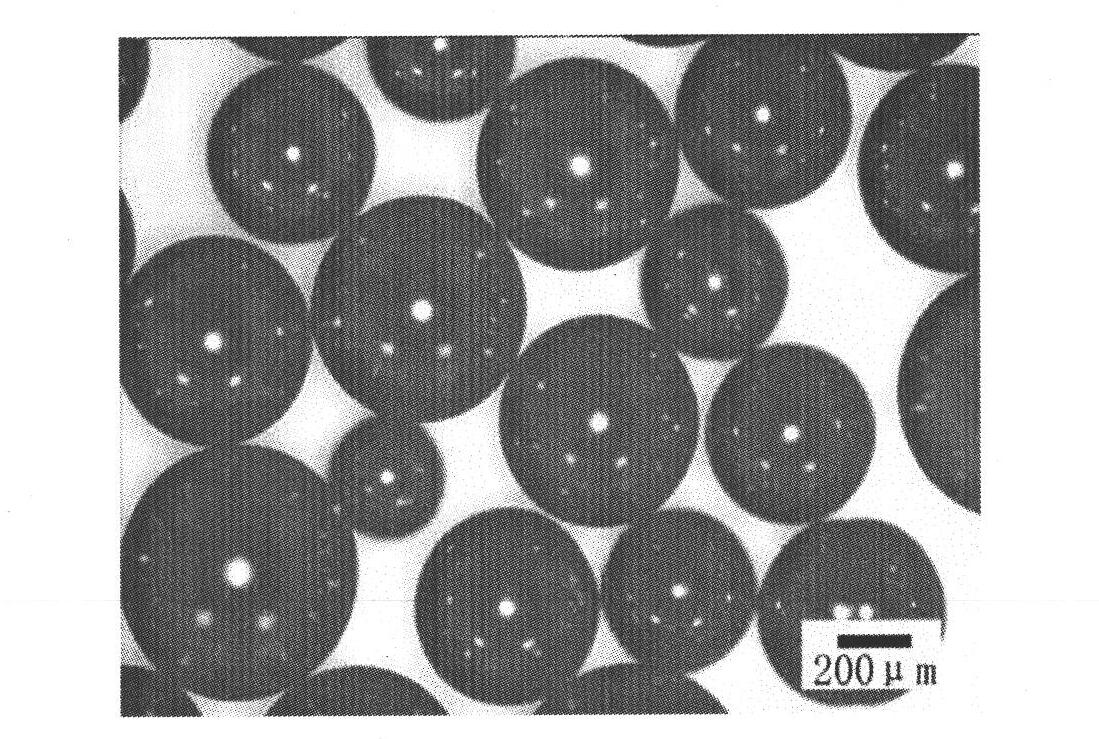

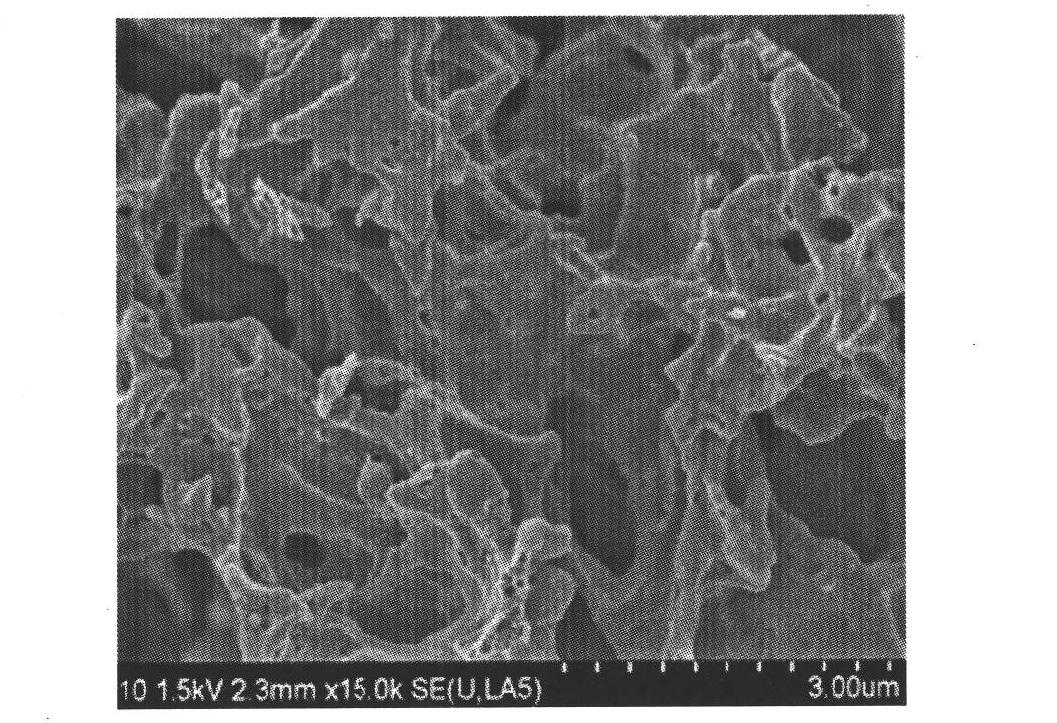

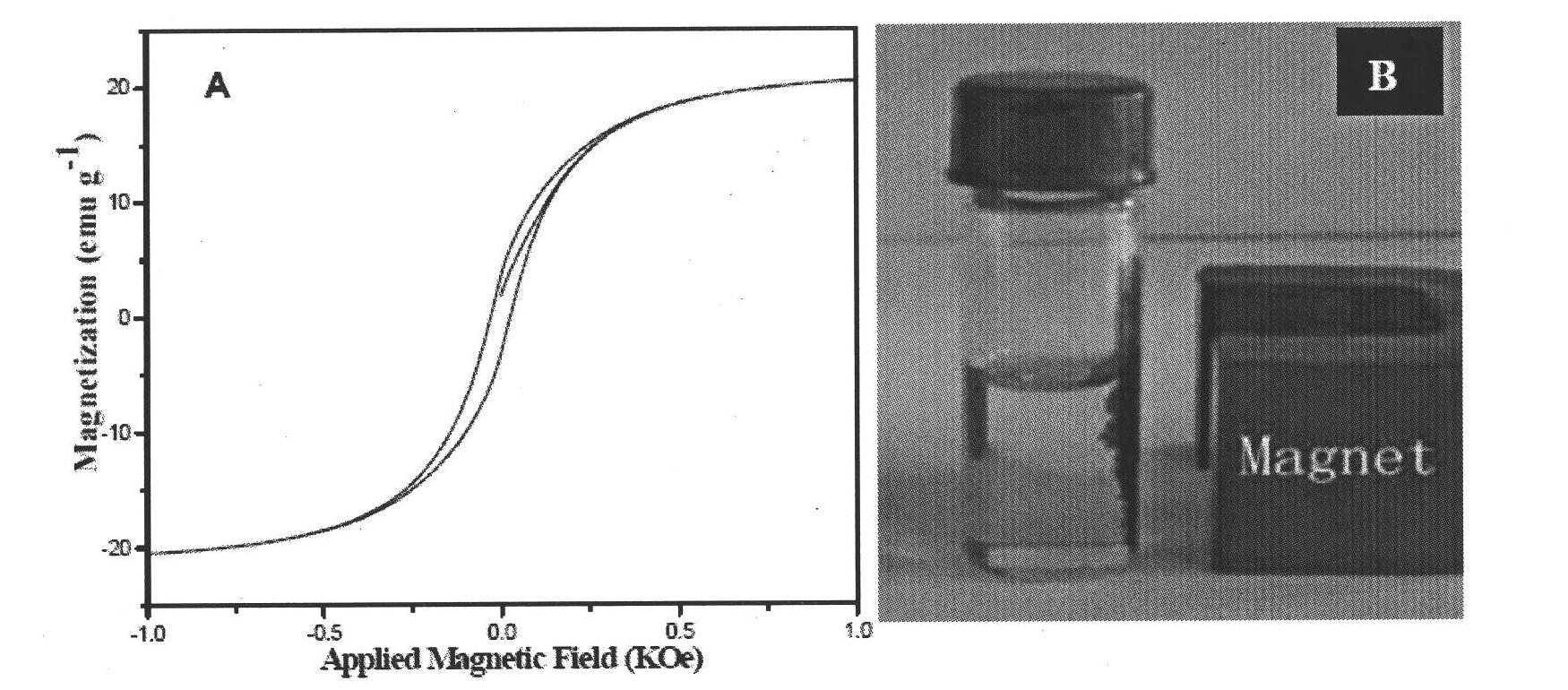

[0028] Dissolve 0.2g of potassium ferricyanide in 50mL of distilled water, then add 2g of anion exchange resin D 280 , fully mixed and stirred at room temperature for 6 hours, fully washed with deionized water for 2 to 3 times, dried overnight at 80°C, and finally placed in a fixed bed reaction tube and roasted at 800°C for 6 hours under nitrogen protection. The nitrogen flow rate is 450ml·min -1 . Spherical carbon-based composites with strong magnetic properties and high crush strength were obtained.

[0029] The sample prepared in embodiment 1 is characterized and analyzed:

[0030] The D 280 (N 2 , 800℃) and Fe / D 280 (N 2 , 800°C) for characterization experiments, the results are shown in Table 1

[0031] Table 1 Specific surface area and porosity analysis data

[0032]

[0033] It can be seen from Table 1 above that: Fe / D 280 (N 2 , 800°C) has a specific surface area of 449m 2 / g, the adsorption mesopore volume is 0.247cm 3 / g; while D 280 (N 2 , 800°C) ...

Embodiment 2

[0037] use D 201 Carbonized resin is made raw material, and other is with embodiment 1.

Embodiment 3

[0039] use D 301 Carbonized resin is made raw material, and other is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com