Preparation method of 2, 5-tetrahydrofuran dimethanol

A technology of tetrahydrofuran dimethanol and furan dimethanol, which is applied in the field of preparation of 2,5-tetrahydrofuran dimethanol, can solve the problems of laboriousness, low product concentration, slow fermentation process, etc., and achieve easy large-scale implementation, easy post-processing, fast The effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

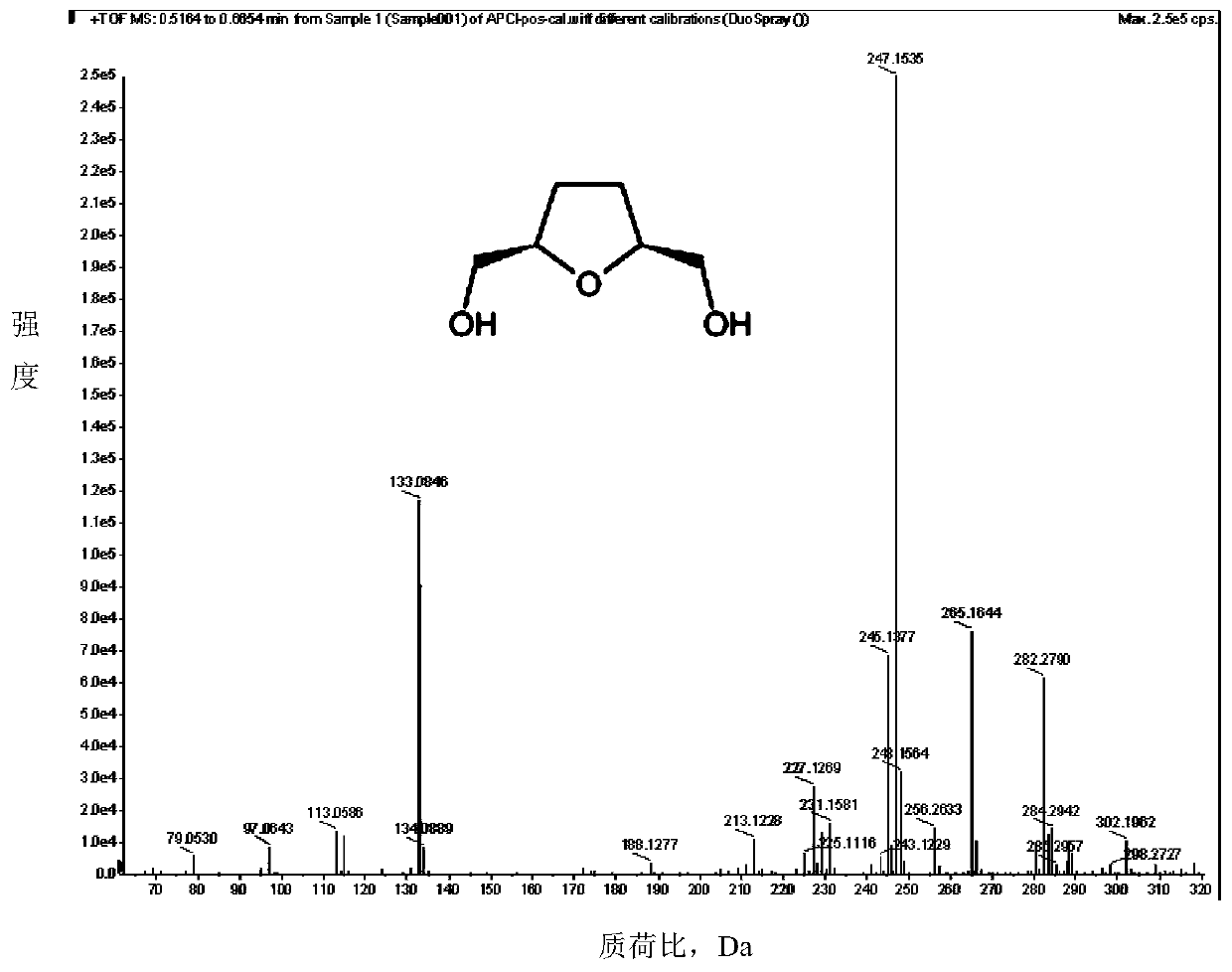

Image

Examples

Embodiment 1

[0056] (1) Add 10g of BHMF and 600ml of absolute ethanol into a beaker, and stir evenly at room temperature. The concentration of the ethanol solution of BHMF is 1.05mM;

[0057] (2) Transfer the solution prepared in step (1) to a 1000ml autoclave. Add 0.25g of 5wt% Pd / C into the reactor, and the mass ratio of the substrate BHMF to the catalyst is 40:1;

[0058] (3) Close the lid of the autoclave, start stirring with 1000rpm, after three vacuum / nitrogen cycles, make the autoclave at 2MpaH 2 The pressure was increased and the temperature was raised to 50°C. After 2 hours, the hydrogen pressure was raised to 4Mpa and the temperature was raised to 70°C. Autoclave continued to keep stirring under this condition for 2 hours;

[0059] (4) After cooling to room temperature, the pressure was released, and the contents in the autoclave were analyzed by GC, and the results are shown in Table 1.

[0060] The reaction result of table 1 embodiment 1

[0061] Example THFDM y...

Embodiment 2

[0063] (1) Add 5g of BHMF and 600ml of absolute ethanol in a beaker, stir evenly at room temperature, wherein the concentration of the ethanol solution of BHMF is 2.1mM;

[0064] (2) Transfer the solution prepared in step (1) to a 1000ml autoclave. Add 0.25g of 5wt% Pd / C into the reactor, and the mass ratio of the substrate BHMF to the catalyst is 40:1;

[0065] (3) Close the lid of the autoclave, start stirring with 1000rpm, after three vacuum / nitrogen cycles, make the autoclave at 2MpaH 2 The pressure was lowered and the temperature increased to 50°C. After 2 hours, the hydrogen pressure increased to 4 MPa, and the temperature increased to 70°C. The autoclave was continued under these conditions with stirring for an additional 2 hours.

[0066] (4) After cooling to room temperature, the pressure was released, and the contents in the autoclave were analyzed by GC, and the results are shown in Table 2.

[0067] The reaction result of table 2 embodiment 2

[0068] ...

Embodiment 3

[0071] (1) Add 10g of BHMF and 600ml of absolute ethanol into a beaker, and stir evenly at room temperature. The concentration of the ethanol solution of BHMF is 0.525mM.

[0072] (2) Transfer the solution prepared in step (1) to a 1000ml autoclave. Add 0.125g of 5wt% Pd / C into the reactor, and the mass ratio of the substrate BHMF to the catalyst is 80:1.

[0073] (3) Close the lid of the autoclave, start stirring with 1000rpm, after three vacuum / nitrogen cycles, make the autoclave at 2MpaH 2 The pressure was lowered and the temperature increased to 50°C. After 2 hours, the hydrogen pressure increased to 4 MPa, and the temperature increased to 70°C. The autoclave was continued under these conditions with stirring for an additional 2 hours.

[0074] (4) After cooling to room temperature, the pressure was released, and the contents in the autoclave were analyzed by GC, and the results are shown in Table 3.

[0075] The reaction result of table 3 embodiment 3

[0076] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com