Scale inhibition particle as well as preparation method and application thereof

A technology of scale inhibition and granules, applied in the field of its preparation and scale inhibition granules, can solve the problems of unmentioned slow release performance, and achieve the effect of wide application range, cost reduction and performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

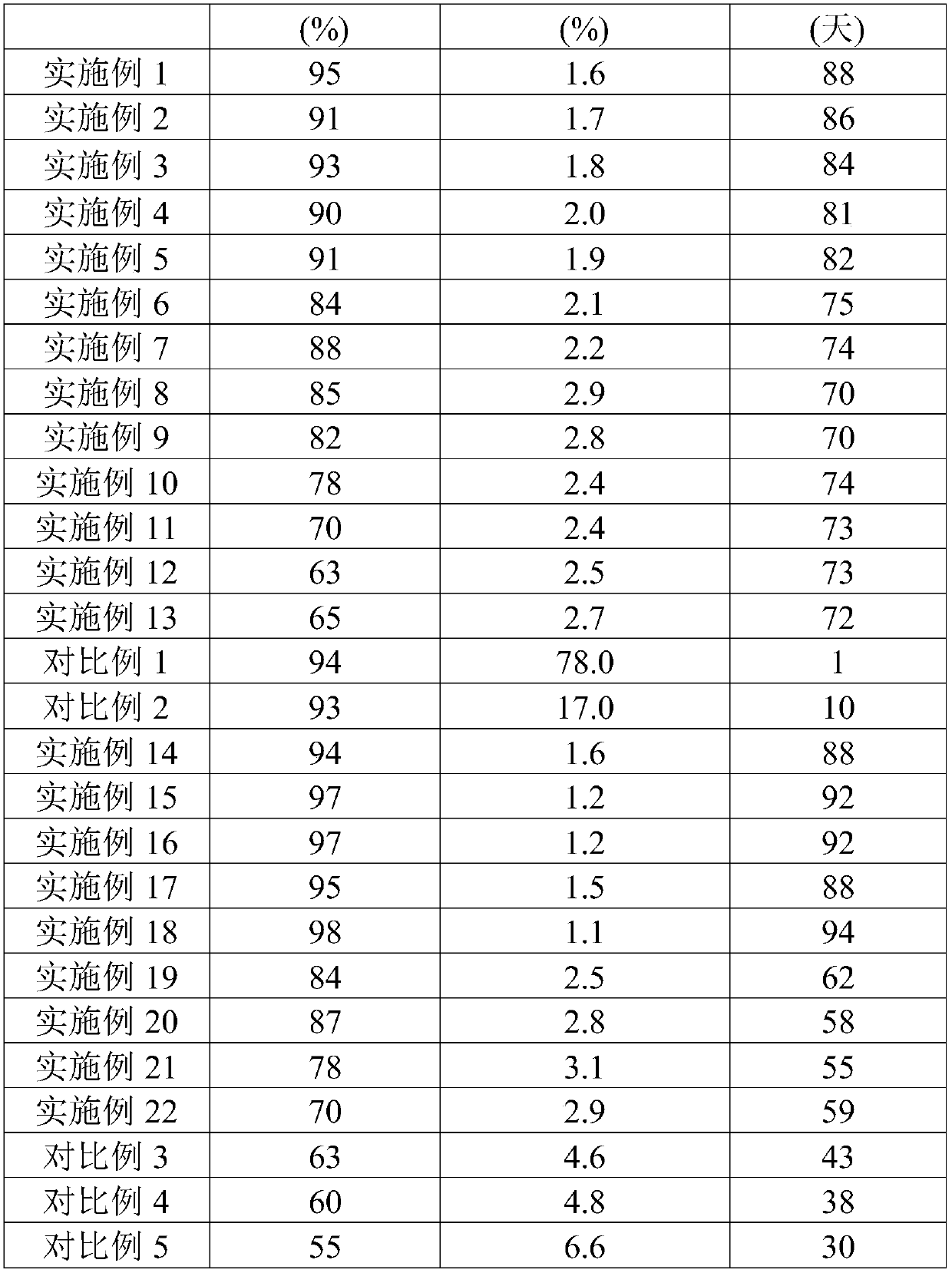

Examples

Embodiment 1

[0093] In this embodiment, a kind of antiscaling granule is provided, the preparation raw material percentage by weight of described antiscaling granule is 42% antiscaling powder, 34% adsorption material and 24% binding agent; Wherein antiscaling powder is organic Antiscaling powder, the binder is a combination of starch and polyethylene, the mass ratio of starch and polyethylene is 1:3, the adsorption material is carbon powder, and the mesh number of carbon powder is 1000 mesh.

[0094] The organic antiscaling powder includes the antiscaling material treated with surfactant hydrophobic, and the antiscaling material includes an antiscaling agent and a mesoporous material carrying the antiscaling agent; wherein the antiscaling agent is polyaspartic acid and poly The combination of acrylic acid; the mass ratio of polyaspartic acid and polyacrylic acid is 1.5:1; the mesoporous material is pure silicon MCM-41; the mesh number of pure silicon MCM-41 is 500 mesh; the scale inhibitor ...

Embodiment 2

[0103] In this embodiment, a kind of antiscaling granule is provided, the preparation raw material percentage by weight of described antiscaling granule is 50% antiscaling powder, 30% adsorption material and 20% binding agent; wherein antiscaling powder is organic Antiscaling powder, the binder is a combination of polyvinyl alcohol and polypropylene, the mass ratio of polyvinyl alcohol and polypropylene is 1:1, the adsorption material is diatomite, and the mesh number of diatomite is 500 mesh.

[0104] The antiscaling powder includes the antiscaling material treated with surfactant hydrophobic, and the antiscaling material includes the antiscaling agent and the mesoporous material loaded on the antiscaling agent; wherein the antiscaling agent is polyaspartic acid and polyacrylic acid The combination; the mass ratio of polyaspartic acid and polyacrylic acid is 1:1; the mesoporous material is diatomite; the mesh number of diatomite is 200 orders; the mass ratio of scale inhibitor...

Embodiment 3

[0113] In this embodiment, a kind of antiscaling granule is provided, the preparation raw material percentage by weight of described antiscaling granule is 35% antiscaling powder, 30% adsorption material and 35% binding agent; Wherein antiscaling powder is organic Antiscaling powder, the binder is a combination of starch and polyethylene, the mass ratio of starch and polyethylene is 1:10, the adsorption material is montmorillonite, and the mesh number of montmorillonite is 1200 mesh.

[0114] The antiscaling powder includes the antiscaling material treated with surfactant hydrophobic, and the antiscaling material includes the antiscaling agent and the mesoporous material loaded on the antiscaling agent; wherein the antiscaling agent is polyaspartic acid and polyacrylic acid The combination; the mass ratio of polyaspartic acid and polyacrylic acid is 3:1; the mesoporous material is activated carbon; the mesh number of activated carbon is 1000 mesh; The agent is stearic acid.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com