A hot stamping and quenching integrated treatment method based on hydroforming device

A technology of hydroforming and processing method, which is applied in the field of metal thermal processing, and can solve problems such as lack of martensitic structure, failure of high-strength steel to reach critical cooling rate, uneven strength of final formed parts, etc., to improve quality, The effect of solving the problem of uneven strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

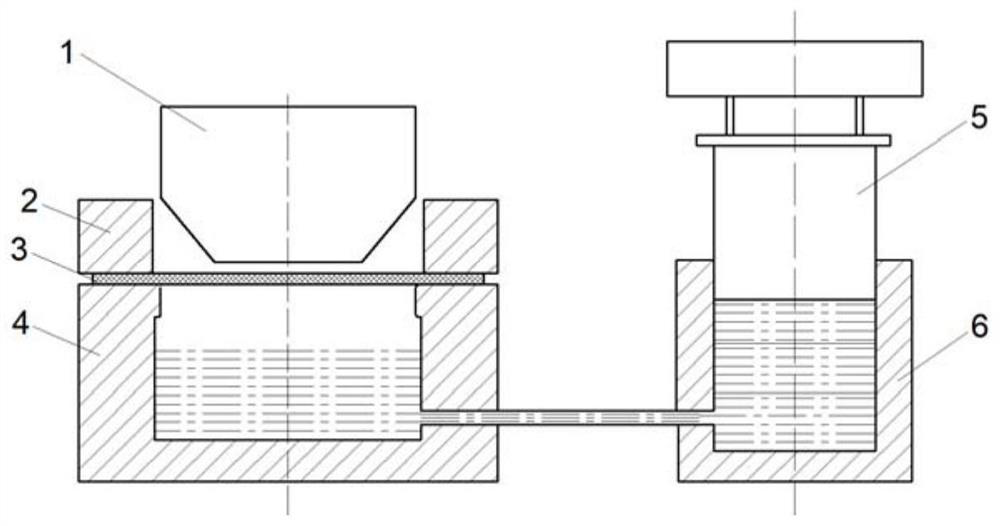

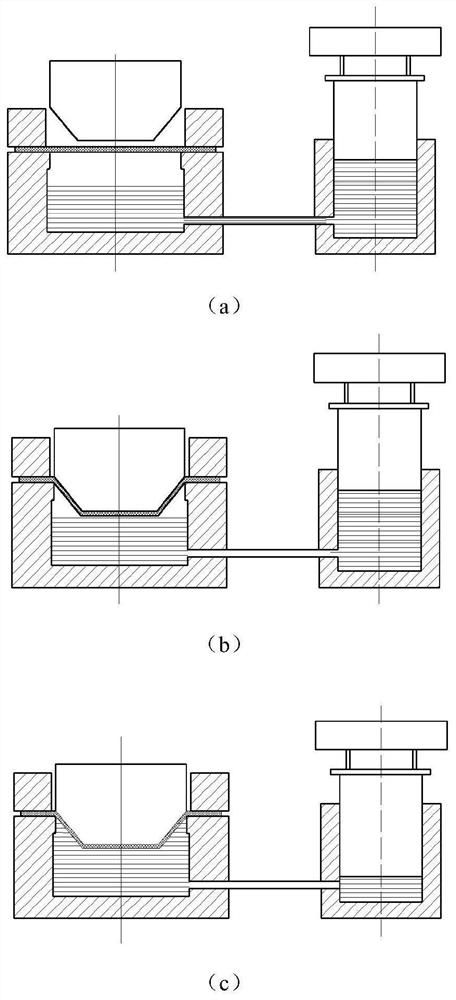

[0022] The invention provides a hot stamping and quenching integrated processing method based on a hydroforming device. The specific steps of the method are as follows:

[0023] (1) The billet is placed in a heating furnace, and the billet is austenitized at a holding temperature of 950° C. after a holding time of 5 minutes.

[0024] (2) The blank obtained in step (1) is quickly moved to the mold of the hydroforming device within 5s, and the amount of liquid in the liquid pool of the mold ensures that the blank does not touch the blank after the mold is pressed together; The temperature was measured with an infrared thermometer.

[0025] (3) The mold is closed quickly, and at the same time, the hydraulic press connected to the liquid pool is started, and the piston moves down, so that the liquid in the liquid pool contacts the blank, and the liquid in the liquid pool fills the liquid pool and forms a certain pressure, The blank is quenched and shaped; the temperature of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com