Cross-conveying heat treatment quenching trough mechanism

A horizontal conveying and quenching tank technology, applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve the problems of face and hand injuries, hidden dangers, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

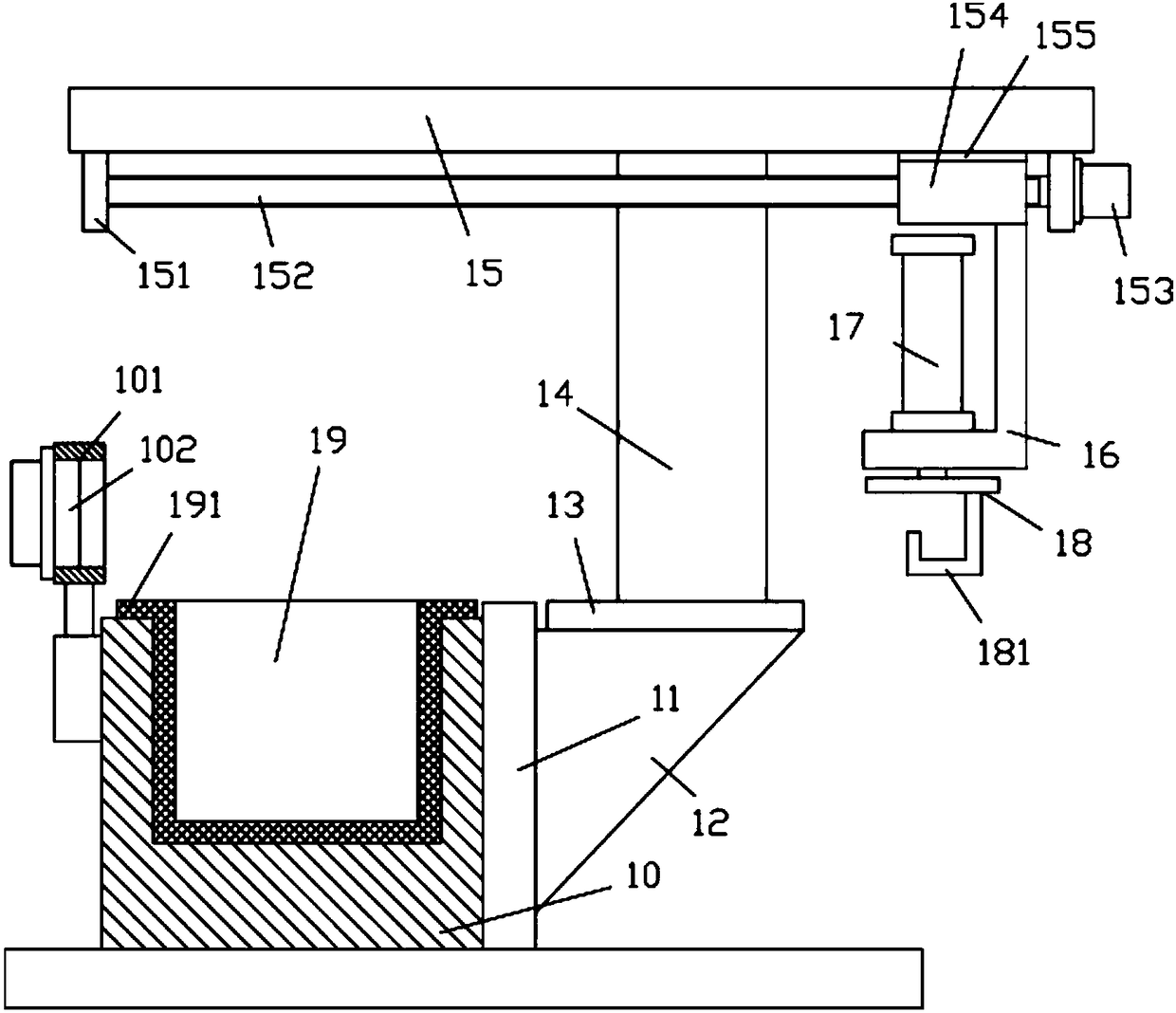

[0012] Examples, see e.g. figure 1 As shown, a heat treatment quenching tank mechanism for horizontal conveyance includes a quenching tank 10, a connecting column 11 is fixed on one side outer wall of the quenching tank 10, and a side connecting block 12 is fixed on the side wall of the connecting column 11, A fixed connection plate 13 is fixed on the side connection block 12, a vertical support plate 14 is fixed in the middle of the fixed connection plate 13, a horizontal plate 15 is fixed on the top of the vertical support plate 14, and the left end of the horizontal plate 15 is at the bottom of the quenching tank 10 Above, the right end of the transverse plate 15 is outside the right side of the quenching tank 10, the left and right ends of the bottom surface of the transverse plate 15 are fixed with support plates 151, and the two ends of the transversely moving screw 152 are hinged on the two support plates 151, one of which A mobile motor 153 is fixed on the outer side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com