Compound for positive electrode material of lithium ion battery, and preparation method and application

A technology for lithium ion batteries and cathode materials, which is applied in the field of electrochemical energy storage, can solve problems such as voltage reduction and specific capacity reduction, and achieves the effects of high reaction yield and simple synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

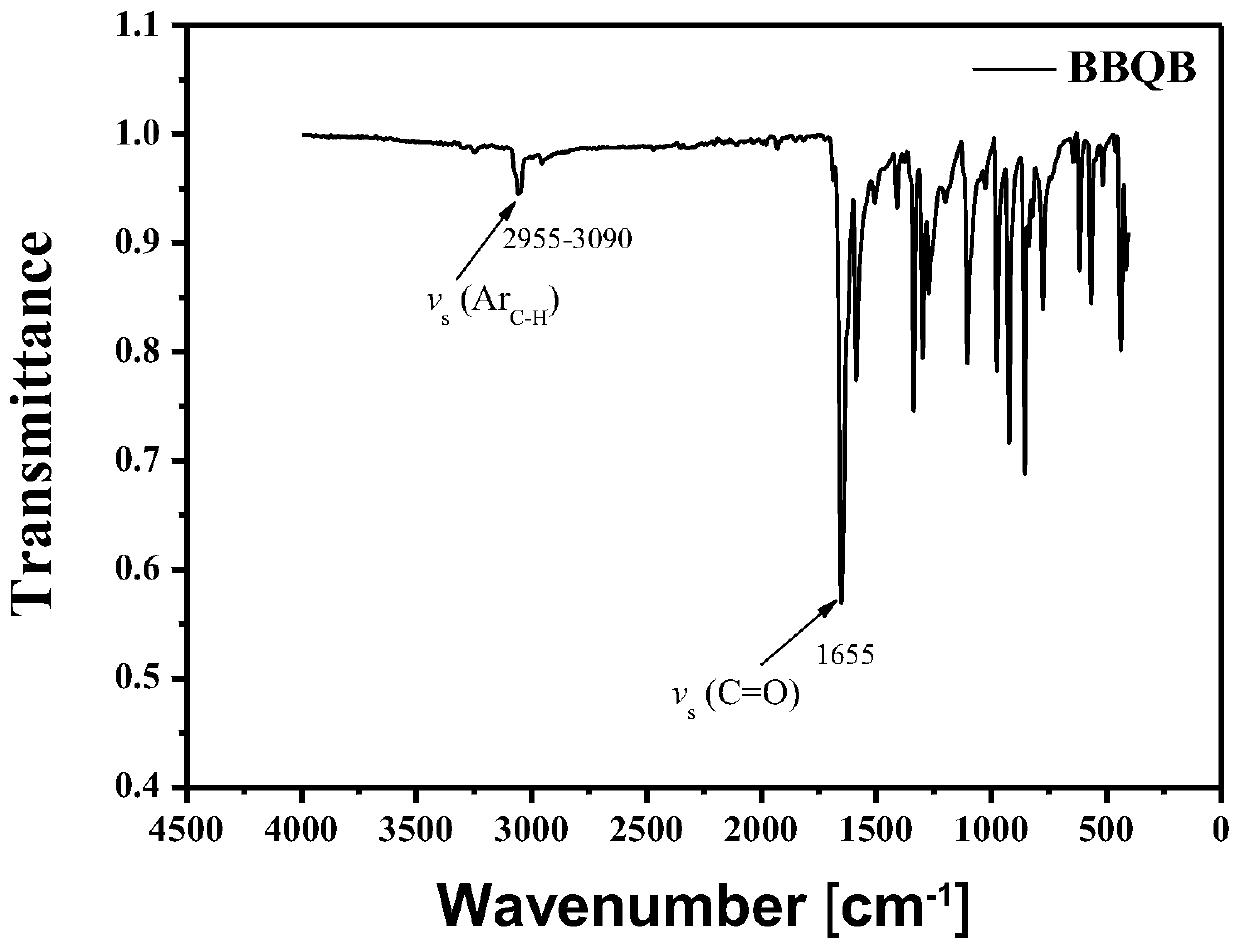

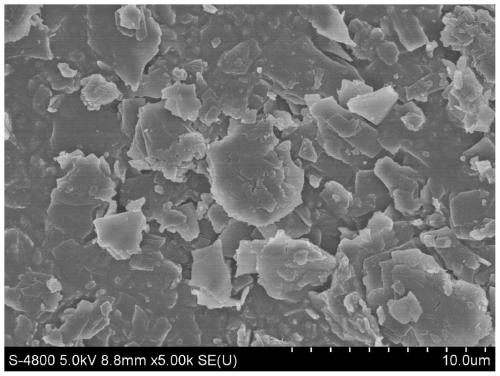

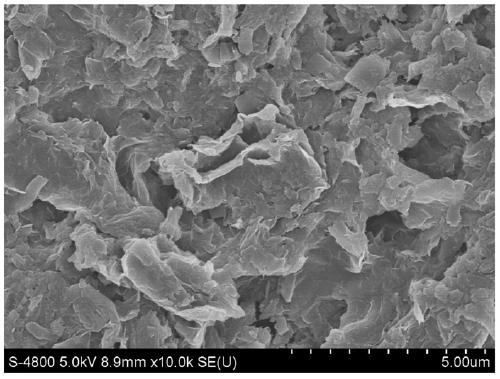

Image

Examples

Embodiment 1

[0036] Embodiment 1-compound synthesis

[0037] In a 100ml branch bottle connected to a double-row tube with a built-in magnet, add 3.55g (19.5mmol, 2.4eqv.) 2,5-dimethoxyphenylboronic acid, 2.00g (8.13mmol, 1.0 eqv.) p-dibromobenzene, 0.750g (0.650mmol, 0.08eqv.) tetrakis (triphenylphosphine) palladium and 3.93g (28.5mmol, 3.5eqv.) potassium carbonate, after pumping nitrogen three times, add in sequence with a syringe Toluene, methanol and water after nitrogen sparging. Heating to 100°C, to mild reflux, and reflux for 10 hours under nitrogen atmosphere. Stop the reaction, after cooling to room temperature, use a rotary evaporator to spin off most of the solvent, add 300 ml of water, extract the aqueous phase with 150 ml of dichloromethane three times, dry the organic phase with anhydrous magnesium sulfate, and separate the crude product by column chromatography , the eluent was petroleum ether: ethyl acetate (8:1), and 1.70 g (67%) of pure product was obtained. 1 H NMR (De...

Embodiment 2

[0039] Example 2-compound synthesis

[0040] In a 100ml three-neck flask connected to a double-row tube, a magnet was built in, and 3.25g (17.9mmol, 2.2eqv.) 2,5-dimethoxyphenylboronic acid, 2.00g (8.13mmol, 1.0eqv.) were added successively .) p-dibromobenzene, 0.469g (0.406mmol, 0.05eqv.) tetrakistriphenylphosphine palladium and 2.25g (16.3mmol, 2.0eqv.) potassium carbonate, after replacing the nitrogen twice, use a constant pressure ground liquid funnel Nitrogen-bubbled toluene, methanol and water were added sequentially. Heat to 70° C., to mild reflux, and reflux under nitrogen atmosphere for 5 hours. Stop the reaction, after cooling to room temperature, use a rotary evaporator to spin off most of the solvent, add 300 ml of water, extract the aqueous phase with 150 ml of dichloromethane three times, dry the organic phase with anhydrous magnesium sulfate, and separate the crude product by column chromatography , the eluent was petroleum ether: ethyl acetate (8:1), and 1.50...

Embodiment 3

[0042] Embodiment 3-compound synthesis

[0043] In a 150ml round-bottomed bottle connected to a double row tube with a built-in magnet, add 4.44g (24.4mmol, 3eqv.) 2,5-dimethoxyphenylboronic acid, 2.00g (8.13mmol, 1.0eqv. .) p-dibromobenzene, 2.250g (1.218mmol, 0.15eqv.) tetrakistriphenylphosphine palladium and 4.49g (32.6mmol, 3.5eqv.) potassium carbonate, after changing the nitrogen four times, add the nitrogen drum in turn with a graduated cylinder After soaking in toluene, methanol and water. Heat to 120° C., to mild reflux, and reflux under nitrogen atmosphere for 24 hours. Stop the reaction, after cooling to room temperature, use a rotary evaporator to spin off most of the solvent, add 300 ml of water, extract the aqueous phase with 150 ml of dichloromethane three times, dry the organic phase with anhydrous magnesium sulfate, and separate the crude product by column chromatography , the eluent was petroleum ether: ethyl acetate (8:1), and 1.85g (72.9%) of pure product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com