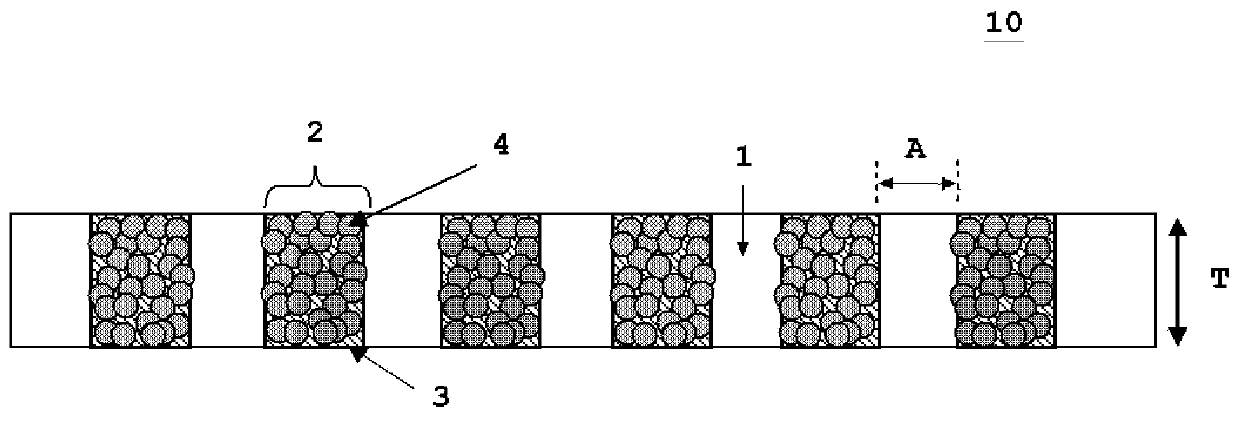

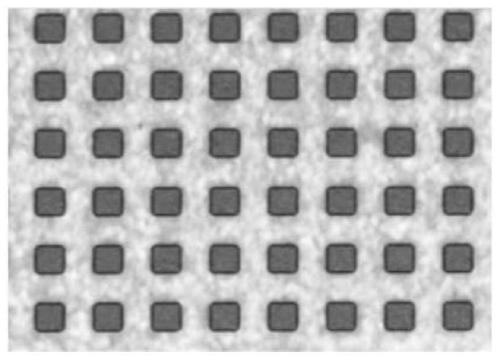

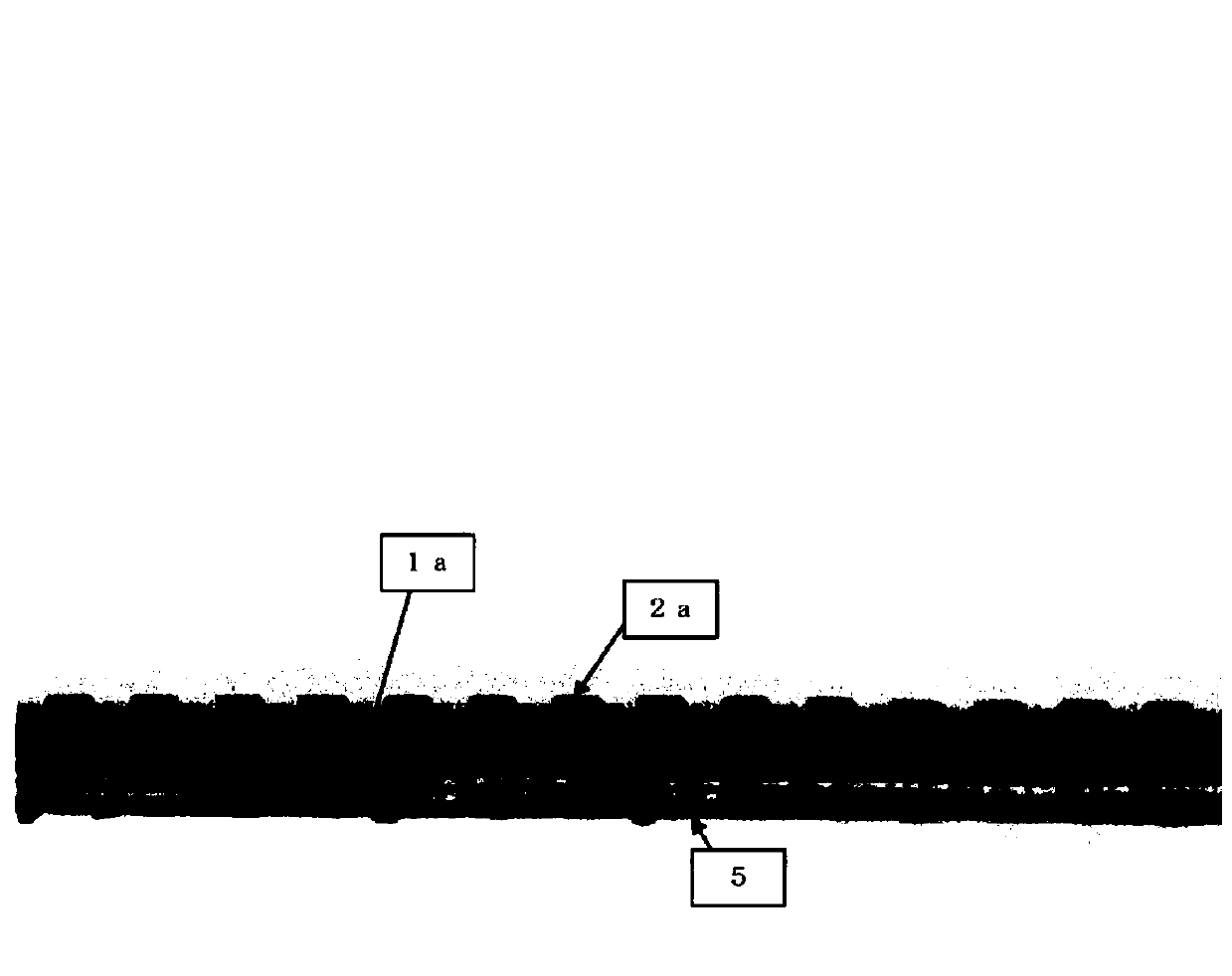

Anisotropic film and method for manufacturing anisotropic film

An anisotropic film, the technology of the manufacturing method, applied in the cable/conductor manufacturing, film/sheet adhesive, film/sheet without carrier, etc., can solve problems such as non-conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0432] Hereinafter, the present invention will be described in more detail by showing synthesis examples, examples, and comparative examples, but the present invention is not limited to the following examples.

[0433] In the following examples, the weight average molecular weight is the weight average molecular weight measured by gel permeation chromatography (GPC) using polystyrene as a standard substance, and the gel permeation chromatography is measured under the following conditions. In addition, in the following synthesis examples, Me is a methyl group, Ph is a phenyl group, and Vi is a vinyl group.

[0434] [measurement conditions]

[0435] Developing solvent: tetrahydrofuran (THF)

[0436] Flow: 0.6mL / min

[0437] Detector: Differential Refractive Index Detector (RI)

[0438] Column: TSK Guardcolumn SuperH-L

[0439] TSKgel SuperH4000 (6.0mm I.D.×15cm×1)

[0440] TSKgel SuperH3000 (6.0mm I.D.×15cm×1)

[0441] TSKgel SuperH2000 (6.0mm I.D.×15cm×2)

[0442] (All m...

Synthetic example 1

[0447] Synthesis of alkenyl-containing organopolysiloxanes

[0448] 1142.1g (87.1mol%) of phenyltrichlorosilane, 529g (3.2mol%) of ClMe 2 SiO(Me 2 SiO) 33 SiMe 2 Cl, and 72.4g (9.7mol%) of dimethyl vinyl chlorosilane dissolved in toluene solvent, drop into water, carry out co-hydrolysis, and further neutralize by washing with water and alkali, after dehydration, remove the solvent by distillation under reduced pressure , to obtain a phenyl group-containing vinyl silicone resin A1 which is solid at 25°C and has a softening point of 45°C. The weight average molecular weight was 63,000. As a result of analyzing the obtained silicone resin A1, it was found to be a silicone resin represented by the following structural formula.

[0449] [chemical formula 14]

[0450]

[0451] In the above formula, the dimethylsiloxane unit means that it has a continuous block structure.

Synthetic example 2

[0453] Synthesis of Organohydrogenpolysiloxanes

[0454] 1142.1g (87.1mol%) of phenyltrichlorosilane, 529g (3.2mol%) of ClMe 2 SiO(Me 2 SiO) 33 SiMe 2 After the methyl dichlorosilane of Cl and 69g (9.7mol%) is dissolved in toluene solvent, drop into water, carry out co-hydrolysis, further carry out neutralization by water washing, alkali washing, after dehydration, underpressure distillation removes solvent, obtains at 25 A phenyl group-containing hydrogen silicone resin A2 that is solid at °C and has a softening point of 40 °C. The weight average molecular weight was 58,000. As a result of analyzing the obtained silicone resin A2, it was found to be a silicone resin represented by the following structural formula.

[0455] [chemical formula 15]

[0456]

[0457] In the above formula, the dimethylsiloxane unit means that it has a continuous block structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com