Composite wear-resistant material for sucker rod elevator and preparation method thereof

A wear-resistant material and sucker rod technology, applied in the field of wear-resistant materials, can solve problems such as damage to the sucker rod, affecting the service life of the sucker rod, knocking, bumping, smashing the sucker rod, etc. Thermal shock resistance, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

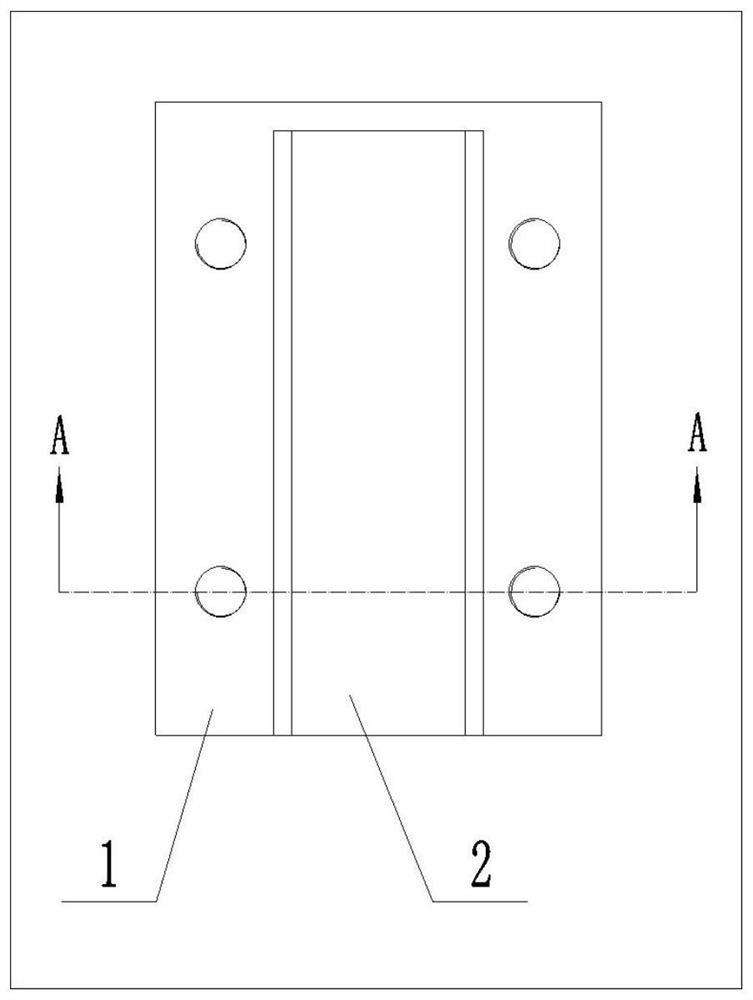

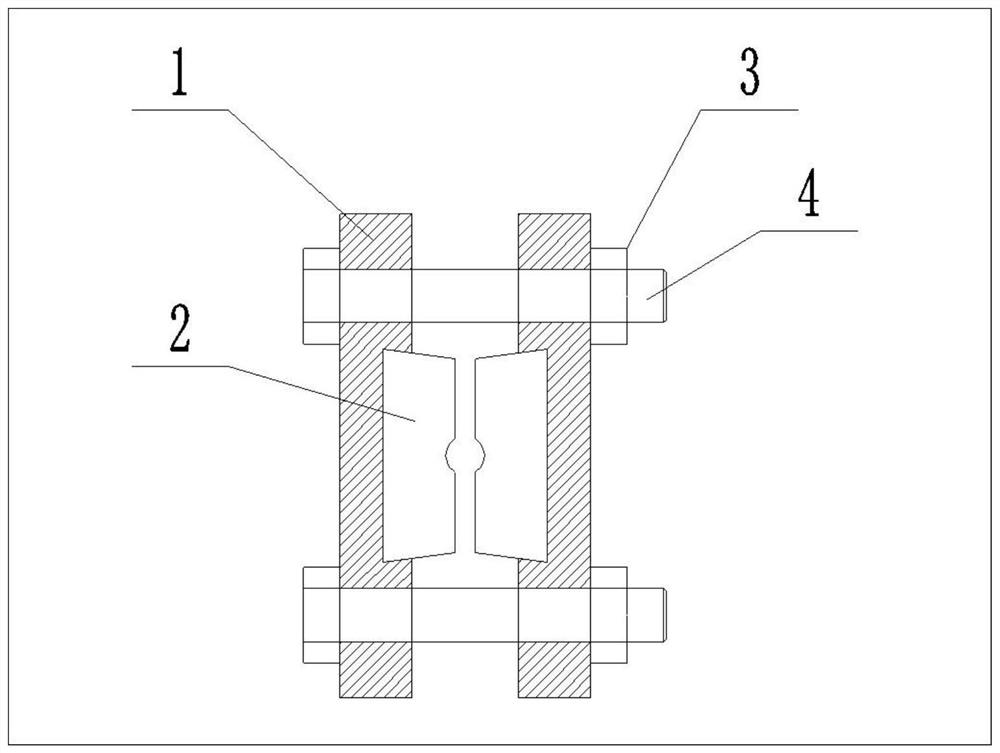

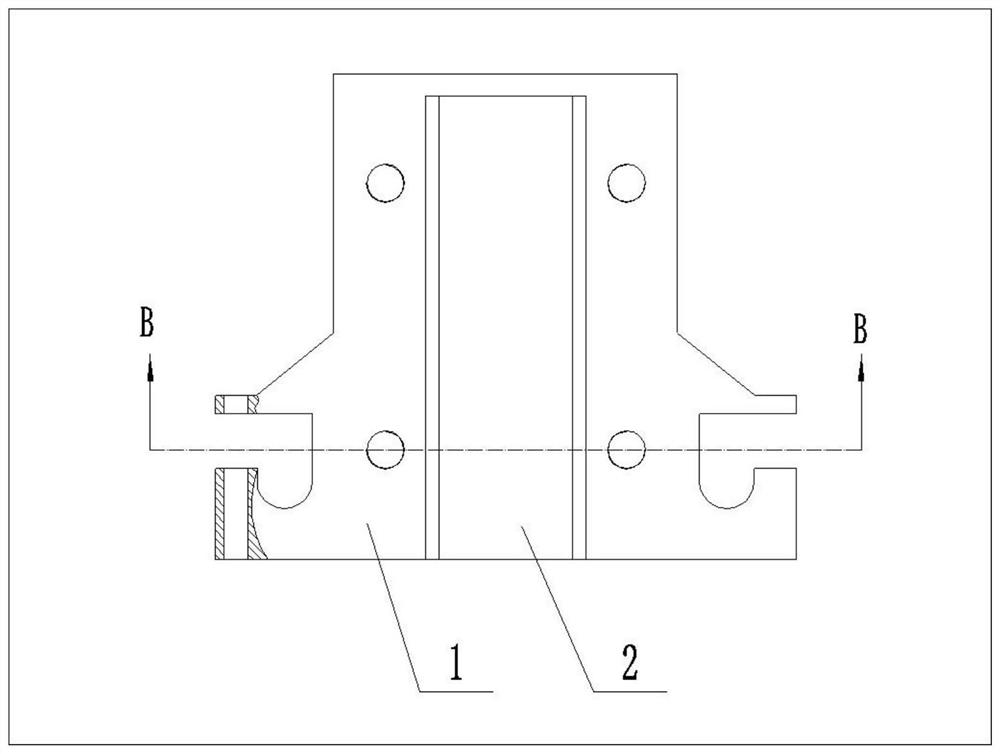

Image

Examples

Embodiment 1

[0033] A composite wear-resistant material for sucker rod elevators, comprising the following raw materials in parts by weight: 15 parts of kaolin, 2 parts of boron carbide, 2 parts of silicon carbide, 2 parts of silicon nitride, 60 parts of chloroprene rubber, and 1 part of graphene , 3 parts of toughening agent, 3 parts of carbon fiber, 3 parts of antioxidant, 1 part of coupling agent, 1 part of crosslinking agent, 3 parts of modifier. Among them, the antioxidant is phosphite, the coupling agent is anilinomethyltriethoxysilane, the crosslinking agent is trienylmethyl triisocyanurate, and the modifier is composed of polyethylene wax and silicone rubber. mixture (mass ratio of polyethylene wax to silicone rubber is 1:2).

Embodiment 2

[0035] A composite wear-resistant material for sucker rod elevators, comprising the following raw materials in parts by weight: 18 parts of kaolin, 3 parts of boron carbide, 3 parts of silicon carbide, 3 parts of silicon nitride, 70 parts of chloroprene rubber, and 2 parts of graphene , 5 parts of toughening agent, 5 parts of carbon fiber, 4 parts of antioxidant, 2 parts of coupling agent, 2 parts of cross-linking agent, 5 parts of modifier. The antioxidant is 2,6-di-tert-butyl-4-methylphenol, the coupling agent is anilinomethyltriethoxysilane, the crosslinking agent is trienylmethyl triisocyanurate, and the modified The agent is a mixture of polyethylene wax and silicone rubber (the mass ratio of polyethylene wax to silicone rubber is 1:2).

Embodiment 3

[0037] A composite wear-resistant material for sucker rod elevators, comprising the following raw materials in parts by weight: 16 parts of kaolin, 3 parts of boron carbide, 2 parts of silicon carbide, 2 parts of silicon nitride, 60 parts of isoprene rubber, and 2 parts of graphene , 4 parts of toughening agent, 4 parts of carbon fiber, 4 parts of antioxidant, 2 parts of coupling agent, 2 parts of cross-linking agent, 4 parts of modifier. Among them, the antioxidant is dibutyldithiocarbamate, the coupling agent is anilinomethyltriethoxysilane, the crosslinking agent is triallyl isocyanurate, and the modifier is polyethylene A mixture of wax and silicone rubber (the mass ratio of polyethylene wax to silicone rubber is 1:2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com