Preparation method of organic silicon-coated polytetrafluoroethylene anti-dripping agent

A technology of polytetrafluoroethylene and anti-drip agent, applied in the chemical industry, can solve the problems of restricting the anti-drip agent, affecting the compatibility of resin, deterioration of material mechanical properties and gloss, etc. Affinity performance, guaranteed mechanical properties and gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of polytetrafluoroethylene anti-dripping agent coated with silicone, the operation steps are:

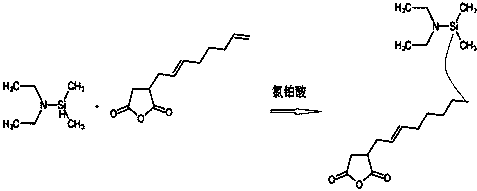

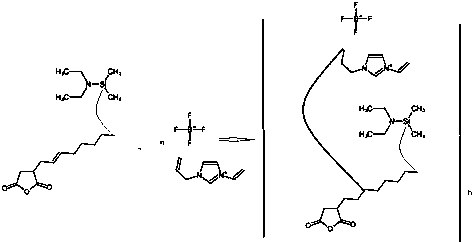

[0026] Add 10g of (2,7-octadien-1-yl) succinic anhydride, 200g of surface-modified polytetrafluoroethylene dispersion into the reactor, then add 0.05g of chloroplatinic acid, 30g of dimethyl Stir silyl diethylamine evenly, then heat up to 80°C; keep warm for 2 hours, then add 0.5g of ammonium persulfate, 0.02g of 1-allyl-3-ethylimidazolium tetrafluoroborate, stir and mix evenly ; keep the temperature at 80°C for 1 hour, add 0.1mol / L sodium hydroxide solution to adjust the pH=8, filter, and dry to obtain the silicone-coated polytetrafluoroethylene anti-dripping agent.

[0027] Described surface-modified polytetrafluoroethylene dispersion liquid, its preparation method is as follows:

[0028] Add 0.1kg of palladium chloride and 0.05kg of stannous chloride into 1000kg of pure water, stir and mix evenly, adjust the pH value to 1 with hydrochloric acid, then...

Embodiment 2

[0034] A preparation method of polytetrafluoroethylene anti-dripping agent coated with silicone, the operation steps are:

[0035] 12g of (2,7-octadien-1-yl) succinic anhydride and 230g of surface-modified polytetrafluoroethylene dispersion were added to the reactor, then 0.09g of chloroplatinic acid and 37g of dimethyl Stir silyl diethylamine evenly, then heat up to 87°C; keep warm for 3 hours, then add 0.9g of ammonium persulfate, 0.06g of 1-allyl-3-ethylimidazolium tetrafluoroborate, stir and mix evenly ; keep the temperature at 85°C for 2 hours, add 0.35mol / L sodium hydroxide solution to adjust the pH=8, filter, and dry to obtain the silicone-coated polytetrafluoroethylene anti-dripping agent.

[0036] Described surface-modified polytetrafluoroethylene dispersion liquid, its preparation method is as follows:

[0037]Add 0.42kg of palladium chloride and 0.27kg of stannous chloride into 1300kg of pure water, stir and mix evenly, adjust the pH value to 2 with hydrochloric a...

Embodiment 3

[0043] A preparation method of polytetrafluoroethylene anti-dripping agent coated with silicone, the operation steps are:

[0044] 16g of (2,7-octadien-1-yl) succinic anhydride, 300g of surface-modified polytetrafluoroethylene dispersion liquid, join in the reactor, then add 0.3g of chloroplatinic acid, 45g of dimethyl Stir silyl diethylamine evenly, then heat up to 95°C; keep warm for 5 hours, then add 2g of ammonium persulfate, 0.2g of 1-allyl-3-ethylimidazolium tetrafluoroborate, stir and mix evenly; Keep the temperature at 95°C for 5 hours, add 0.5mol / L sodium hydroxide solution to adjust the pH to 10, filter, and dry to obtain the silicone-coated polytetrafluoroethylene anti-dripping agent .

[0045] Described surface-modified polytetrafluoroethylene dispersion liquid, its preparation method is as follows:

[0046] Add 0.84kg of palladium chloride and 0.52kg of stannous chloride into 1500kg of pure water, stir and mix evenly, adjust the pH value to 3 with hydrochloric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com