Composite photocatalyst for producing hydrogen peroxide and its preparation method and application

A technology of hydrogen peroxide and catalyst, applied in the field of photocatalysis, to achieve excellent visible light and near-infrared light conversion ability, improve separation efficiency, and expand the effect of intrinsic light absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

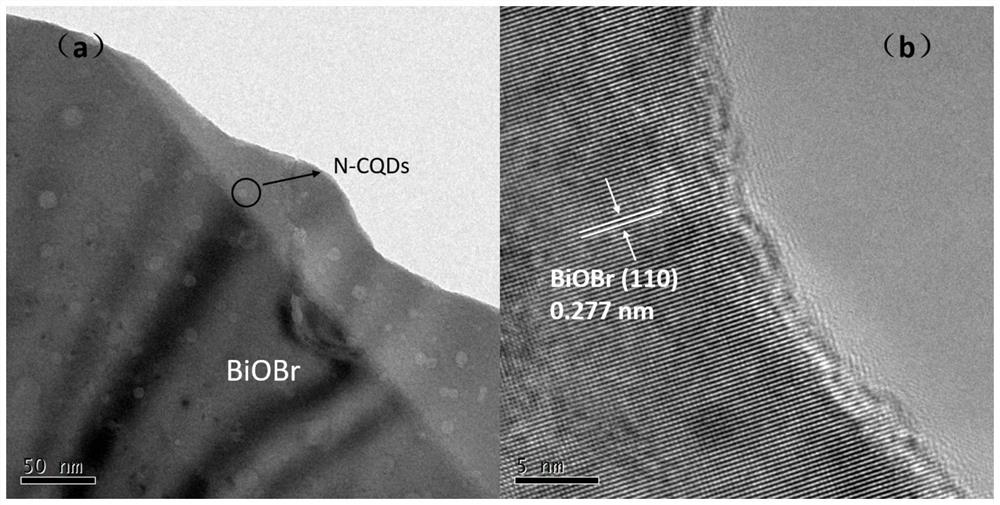

[0073] A bismuth oxybromide composite photocatalyst with oxygen vacancies modified by nitrogen-doped carbon quantum dots, the bismuth oxybromide composite photocatalyst with oxygen vacancies modified by nitrogen-doped carbon quantum dots is supported by bismuth oxybromide with oxygen vacancies , Bismuth oxybromide is decorated with nitrogen-doped carbon quantum dots.

[0074] In this embodiment, the volume of the nitrogen-doped carbon quantum dot dispersion in the nitrogen-doped carbon quantum dot-modified bismuth oxybromide composite photocatalyst with oxygen vacancies is 6 mL.

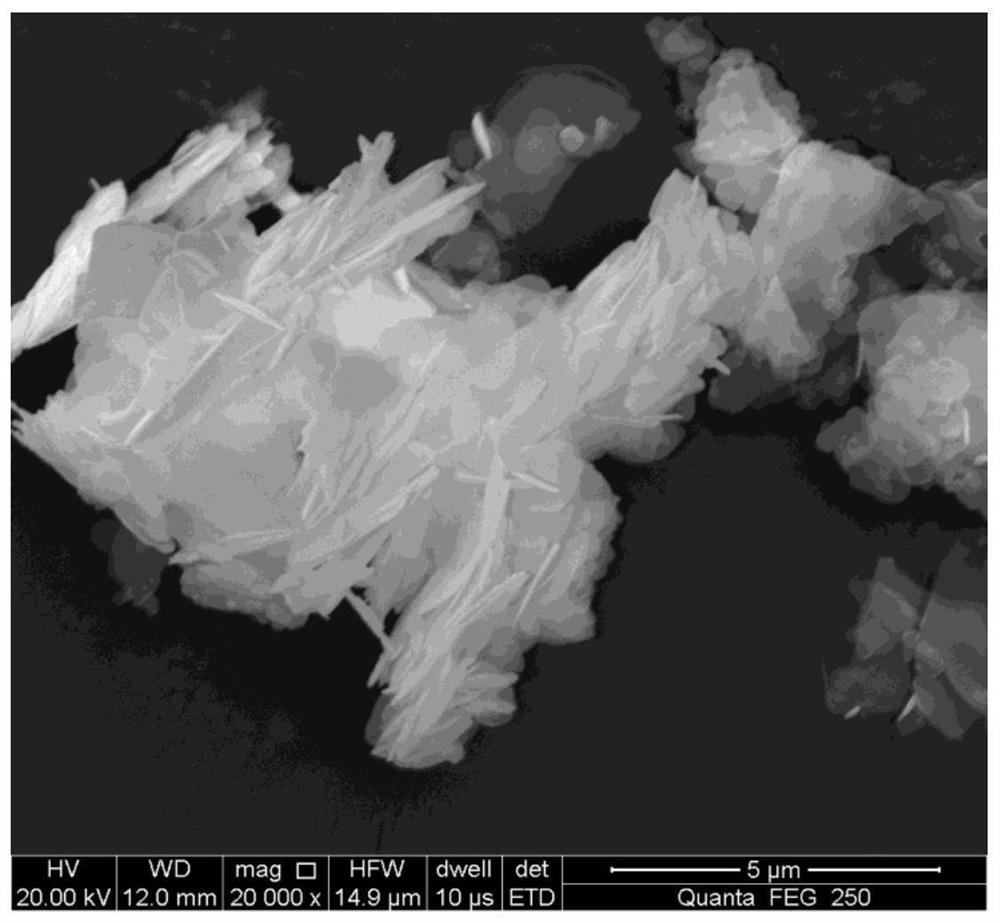

[0075] In this embodiment, the nitrogen-doped carbon quantum dot-modified bismuth oxybromide composite photocatalyst with oxygen vacancies is a sheet material with a diameter of 3 μm-6 μm and a thickness of 100 nm-300 nm.

[0076] In this embodiment, the nitrogen-doped carbon quantum dots are spherical materials with a diameter of 2 nm to 10 nm.

[0077] The preparation method of the bismuth oxybrom...

Embodiment 2

[0119] Application of a nitrogen-doped carbon quantum dot modified bismuth oxybromide composite photocatalyst with oxygen vacancies in the production of hydrogen peroxide, comprising the following steps:

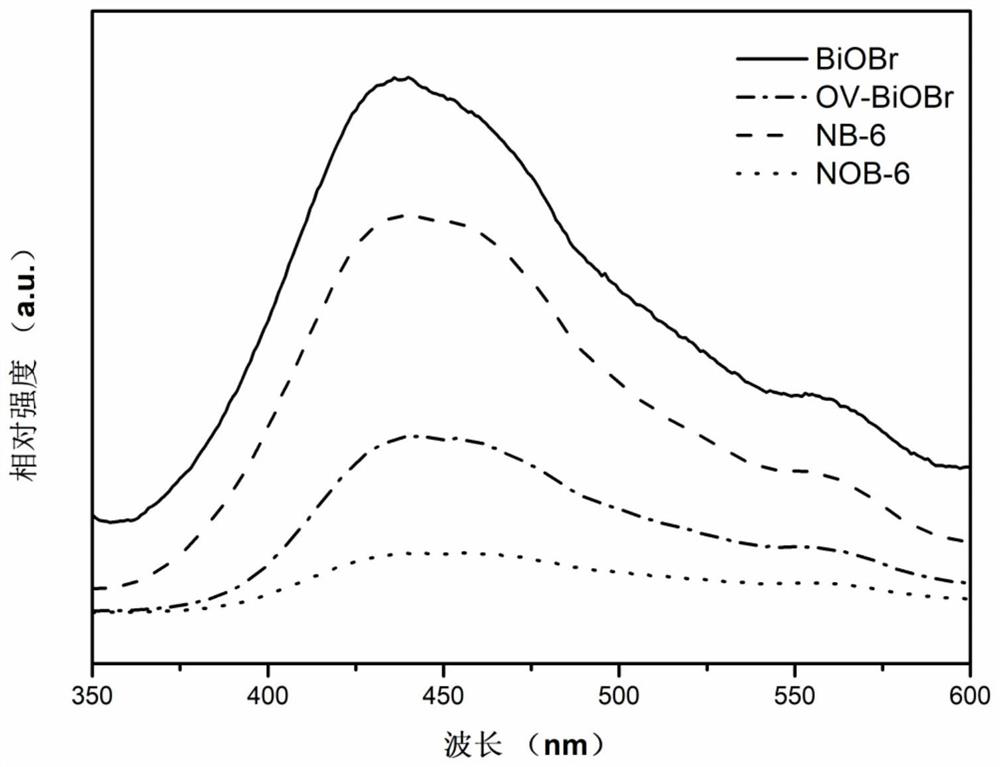

[0120] Weigh respectively BiOBr (comparative example 1), NB-6 (comparative example 2), OV-BiOBr (comparative example 3), NOB-6 (embodiment 1) of 0.05g, and add them to 100mL, volume concentration respectively In a 10% aqueous solution of isopropanol, stir magnetically for one hour in a dark place (that is, under dark conditions), turn on the light source after reaching adsorption equilibrium, and carry out a photocatalytic reaction under visible light (λ≥420nm) for 60 minutes to complete the production of hydrogen peroxide .

[0121] In this embodiment, 100 mL of isopropanol solution with a volume concentration of 10% without adding any material is used as a blank for comparison.

[0122] Determination of hydrogen peroxide production: absorb the photocatalytic reaction solu...

Embodiment 3

[0130] To investigate the reusability of nitrogen-doped carbon quantum dots modified bismuth oxybromide composite photocatalyst with oxygen vacancies in the process of photocatalytic production of hydrogen peroxide, including the following steps:

[0131] (1) Weigh 0.05g of the bismuth oxybromide composite photocatalyst (NOB-6) with oxygen vacancies modified by nitrogen-doped carbon quantum dots prepared in Example 1, add to 100mL, volume concentration of 10% isopropanol In aqueous solution, the reaction system was obtained.

[0132] (2) Place the reaction system (isopropanol solution with NOB-6 added) obtained in step (1) on a magnetic stirrer, and stir for 1 h in the dark to achieve adsorption equilibrium, and take 3 mL of the solution to represent the The initial solution, that is, the solution when the reaction time is 0min, after filtration and color development, measure its concentration with a UV-visible spectrophotometer and convert it into output.

[0133] (3) The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com