A kind of porous ternary cu-znni alloy material and its preparation method and application

An alloy material and alloy technology, applied in the field of porous ternary Cu-ZnNi alloy material and its preparation, can solve the problem of difficulty in obtaining porosity and corrosion resistance, achieve good throwing and deep plating ability, reduce production cost, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

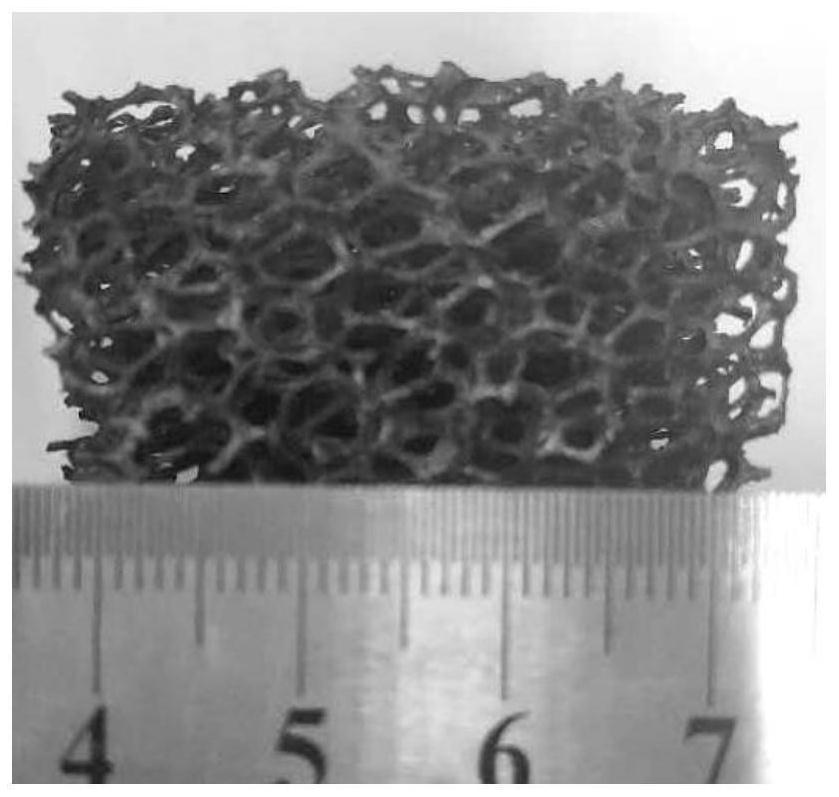

[0024] The invention provides a method for preparing a porous ternary Cu-ZnNi alloy material, comprising the following steps:

[0025] The open-cell flexible polyurethane foam is sequentially subjected to degreasing treatment and roughening treatment to obtain a roughened flexible polyurethane foam;

[0026] The roughened flexible polyurethane foam is dip-coated with conductive glue, and then cured to obtain rigid polyurethane foam;

[0027] The rigid polyurethane foam is alternately electroplated copper and electroplated zinc-nickel alloy to obtain a porous ternary Cu-ZnNi alloy material precursor; the zinc-nickel alloy plating solution used for electroplating zinc-nickel alloy is zinc salt, nickel salt and boric acid The mixed aqueous solution; the concentration of the zinc salt and nickel salt is based on the concentration of metal ions, the concentration of the zinc salt is 0.14~0.74mol / L, the concentration of the nickel salt is 0.61~0.78mol / L, the The concentration of bo...

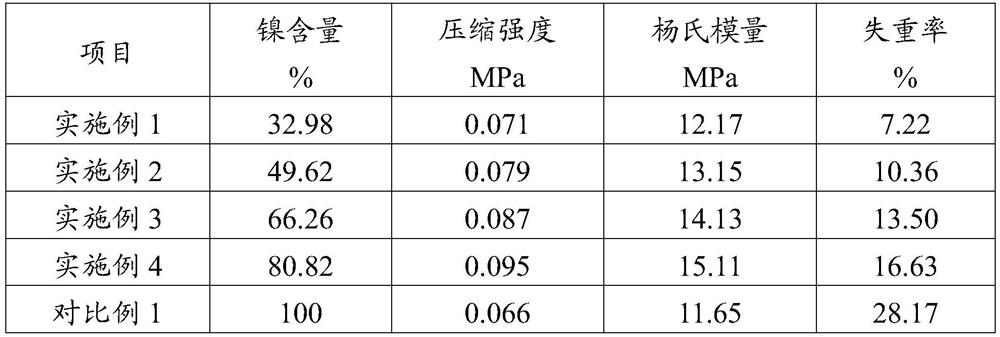

Embodiment 1

[0060] The open-cell flexible polyurethane foam with a porosity of 80% was ultrasonically cleaned at a power of 20 kHz for 10 min in distilled water, then placed in a sodium hydroxide solution (1 mol / L) with a pH value of 12, and ultrasonically treated at a power of 20 kHz 25min for alkali washing; the open-cell flexible polyurethane foam after alkali washing was taken out and soaked in distilled water, ultrasonically cleaned for 10min at a power of 20kHz, and then placed in a hydrochloric acid solution (1mol / L) with a pH value of 1. Power ultrasonic treatment for 5 minutes for pickling; soak the open-cell flexible polyurethane foam after pickling in distilled water, and ultrasonically clean it with a power of 20 kHz for 8 minutes to obtain degreasing flexible polyurethane foam;

[0061] Immerse the degreasing soft polyurethane foam in the roughening solution, squeeze repeatedly until no bubbles are produced, then roughen at room temperature for 25 hours, wherein the concentrat...

Embodiment 2

[0069] The open-cell flexible polyurethane foam with a porosity of 90% was ultrasonically cleaned at a power of 30 kHz for 8 min in distilled water, then placed in a potassium hydroxide solution (2 mol / L) with a pH value of 12, and ultrasonically treated at a power of 30 kHz Alkali washing was carried out for 30 min; the open-cell flexible polyurethane foam after alkali washing was taken out and soaked in distilled water, ultrasonically cleaned at a power of 30 kHz for 8 min, and then placed in a nitric acid solution (1mol / L) with a pH value of 1. Power ultrasonic treatment for 10 minutes for pickling; soak the open-cell flexible polyurethane foam after pickling in distilled water, and ultrasonically clean it with a power of 30 kHz for 8 minutes to obtain degreasing flexible polyurethane foam;

[0070] Immerse the degreasing soft polyurethane foam in the roughening solution, squeeze repeatedly until no bubbles are produced, then roughen at room temperature for 30 hours, wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com