Application of quaternary ammonium salt type anthraquinone active substance and organic water-phase salt cavern battery

A technology of active material and negative active material, applied in the field of organic water-phase salt cavern battery, can solve problems such as limited solubility, and achieve the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

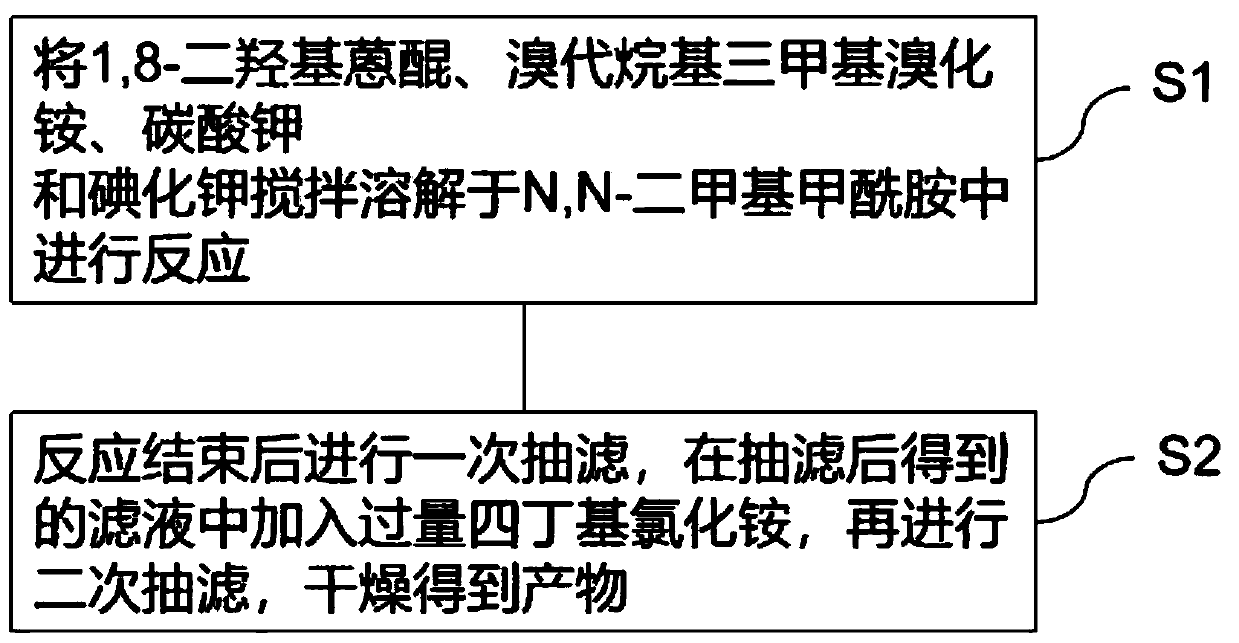

[0046] Such as figure 1 As shown, in some specific embodiments of the present invention, the preparation method of the quaternary ammonium salt type anthraquinone active substance comprises the following steps:

[0047] S1. 1,8-dihydroxyanthraquinone, bromoalkyltrimethylammonium bromide, potassium carbonate and potassium iodide are stirred and dissolved in N,N-dimethylformamide (DMF) for reaction.

[0048] Optionally, bromoalkyltrimethylammonium bromide (Br-(CH 2 )nN + (CH 3 ) 3 Br - ) in the alkyl chain n=1,2,3.....12.

[0049] According to one embodiment of the present invention, the molar ratio of the reactants in step S1 is: 1,8-dihydroxyanthraquinone:bromoalkyltrimethylammonium bromide:potassium carbonate:potassium iodide:N,N-dimethyl Formamide=1:2~5:2~8:0.01~0.1:10~100.

[0050] In some specific embodiments of the present invention, the reaction temperature in step S1 is 100°C to 200°C, and the reaction time is 10h to 48h, that is to say, 1,8-dihydroxyanthraquinon...

Embodiment 1

[0072] Preparation of anthraquinone type active substances:

[0073] 1,8-dihydroxyanthraquinone and Br-(CH 2 ) 3 N + (CH 3 ) 3 Br - , and potassium carbonate and potassium iodide were stirred and dissolved in N,N-dimethylformamide (DMF) in a certain proportion. Among them, the reactant 1,8-dihydroxyanthraquinone: Br-(CH 2 ) 3 N + (CH 3 ) 3 Br - : Potassium carbonate: Potassium iodide: The molar ratio of DMF is 1:3:5:0.05:50.

[0074] React at 140°C for 24 hours, cool to room temperature after completion, and filter with suction. After suction filtration, add excess tetrabutylammonium chloride to the filtrate, perform suction filtration, and dry in vacuo to obtain the product.

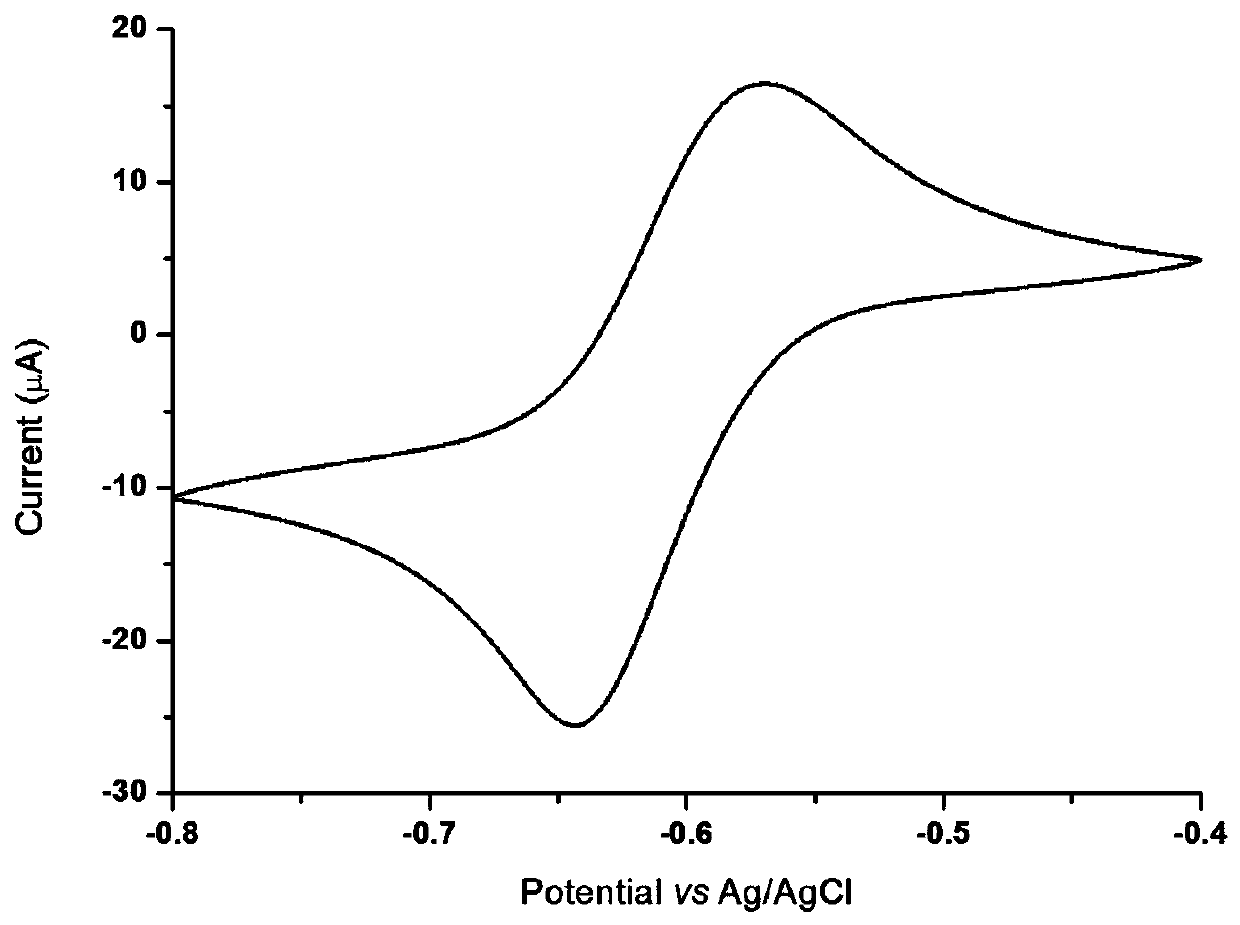

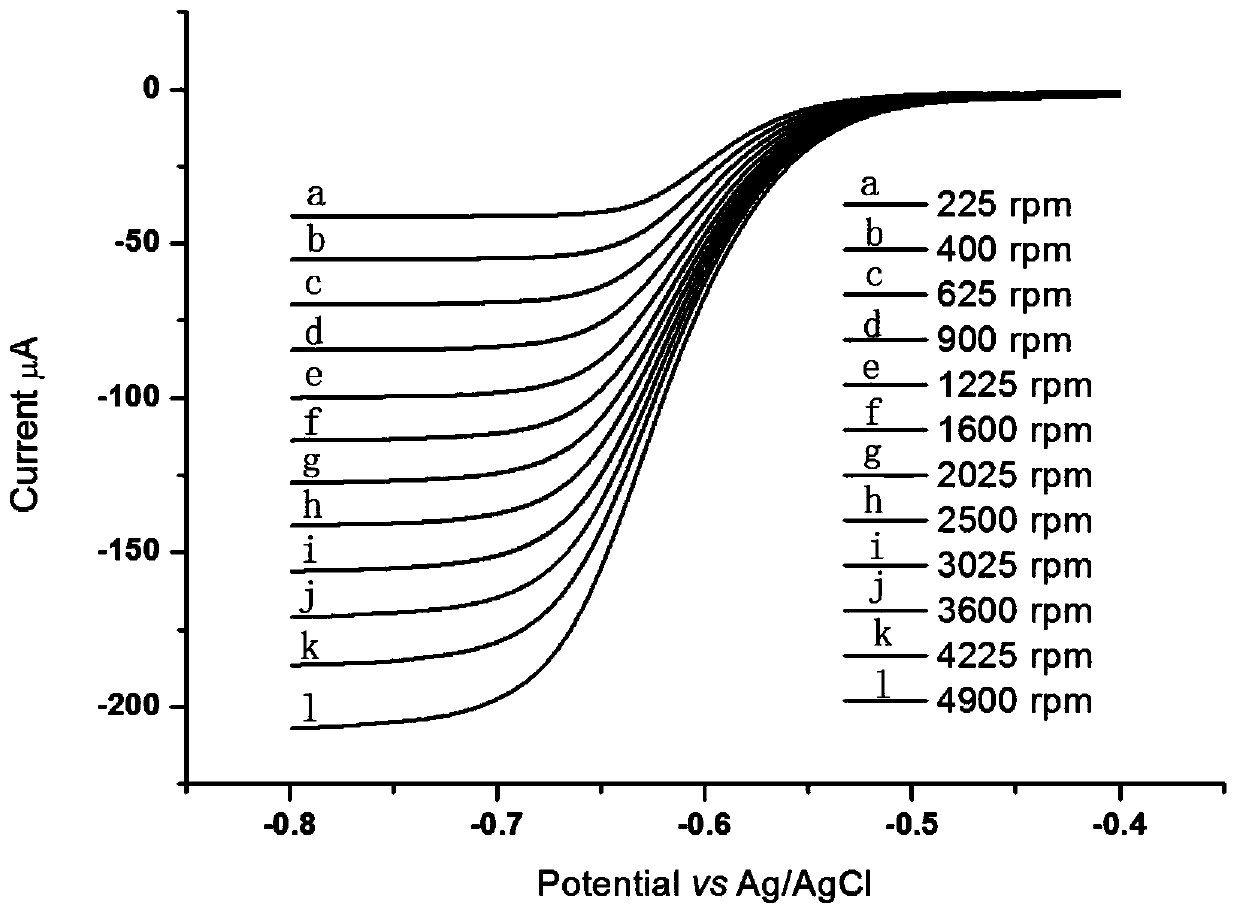

[0075] Figure 2 to Figure 9 In order to characterize the electrochemical performance of the prepared active material, the diffusion coefficient of the prepared quaternary ammonium salt type anthraquinone active material on the graphite felt electrode is 3.94×10 -6 cm 2 / s, the charge tra...

Embodiment 2

[0084] Preparation of anthraquinone type active substances:

[0085] 1,8-dihydroxyanthraquinone and Br-(CH 2 ) 2 N + (CH 3 ) 3 Br - , and potassium carbonate and potassium iodide were stirred and dissolved in N,N-dimethylformamide (DMF) in a certain proportion. Where reactant Br-(CH 2 ) 2 N + (CH 3 ) 3 The molar ratio of Br: potassium carbonate: potassium iodide: DMF is 1:3:6:0.02:60.

[0086] React at 160°C for 20 hours, cool to room temperature after completion, and filter with suction. After suction filtration, add excess tetrabutylammonium chloride to the filtrate, perform suction filtration, and dry in vacuo to obtain the product.

[0087] Battery performance test:

[0088] The underground depth is 900m, and the physical volume is 150,000m 3 , with a height of 120m, a maximum diameter of 80m, and two salt caverns with a geothermal temperature of 37°C are used as storage tanks for the yin and yang electrolytes. The inner diameter of the casing is 30cm and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diffusion coefficient | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com