Double-crystal hard alloy and preparation method thereof

A cemented carbide and grain technology, applied in the field of cemented carbide, can solve the problems of adverse effects on the performance of the alloy and the inability to eliminate the agglomeration of WC grains, and achieve complete grain crystallization, less grain defects, and narrow particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

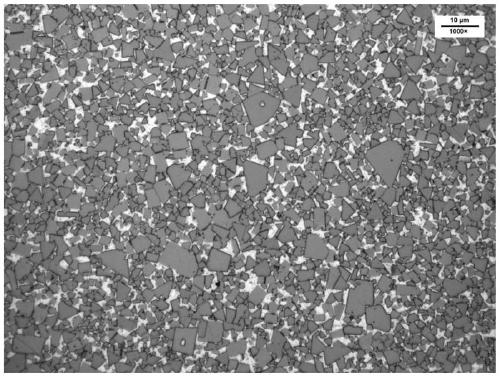

Embodiment 1

[0040] The first tungsten carbide powder with an average particle size of 10 μm is classified by the airflow classification method to obtain the second single crystal tungsten carbide powder with an average particle size of 3 μm; the particle size of 60wt% of the total weight of the WC powder is first calculated by using a ball-to-material ratio of 10. The first WC powder of 10 μm is carried out intensive ball milling, ball milling 30 hours; Then add the second WC powder that accounts for 40wt% of WC powder gross weight and be the second WC powder of 3 μm and account for raw material (comprising the first WC powder, the second WC powder and Co powder) Co powder with a total weight of 12wt% is ball milled for 6 hours before unloading, and then granulated---pressed---sintered at 1480°C for 1.5h to obtain a structure with uniform distribution of 1.6-2.0μm and 5-10μm tungsten carbide grains Structure, denoted as WC-12wt% Co, the hardness of the twin crystal cemented carbide prepare...

Embodiment 2

[0044] The first tungsten carbide powder with an average particle size of 10 μm is classified by the airflow classification method to obtain the second single crystal tungsten carbide powder with an average particle size of 5 μm; the particle size of 70wt% of the total weight of the WC powder is first calculated by using a ball-to-material ratio of 12. The first WC powder of 10 μm is carried out intensive ball milling, and ball milling is 39 hours; Then add the second WC powder that accounts for 30wt% of WC powder gross weight and be the second WC powder of 5 μm and account for raw material (comprising the first WC powder, the second WC powder and Co powder) Co powder with a total weight of 16wt% is ball milled for 10 hours before unloading, then granulated --- pressed --- sintered at 1450 ° C for 2.0 hours to obtain a structure with uniform distribution of tungsten carbide grains of 1.6-2.0 μm and 5-10 μm The structure is denoted as WC-16wt% Co, and the hardness of the twin cr...

Embodiment 3

[0048] The first tungsten carbide powder with an average particle size of 10 μm is classified by the airflow classification method, and the second single crystal tungsten carbide powder with an average particle size of 7 μm is obtained; the particle size of 80wt% of the total weight of the WC powder is first obtained by using a ball-to-material ratio of 15. The first WC powder of 20 μm is carried out intensive ball milling, ball milling 48 hours; Then add the second WC powder that accounts for 20wt% of WC powder gross weight and be the second WC powder of 7 μm and account for raw material (comprising first WC powder, the second WC powder and Co powder) Co powder with a total weight of 8wt% is ball milled for 14 hours before unloading, and then granulated---pressed---sintered at 1520°C for 0.5h to obtain a structure with uniform distribution of 1.6-2.0μm and 5-10μm tungsten carbide grains Structure, denoted as WC-8wt% Co, the hardness of the twin crystal cemented carbide prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com