Titanium carbonitride-based cermet with metal-rich phase gradient structure and preparation method thereof

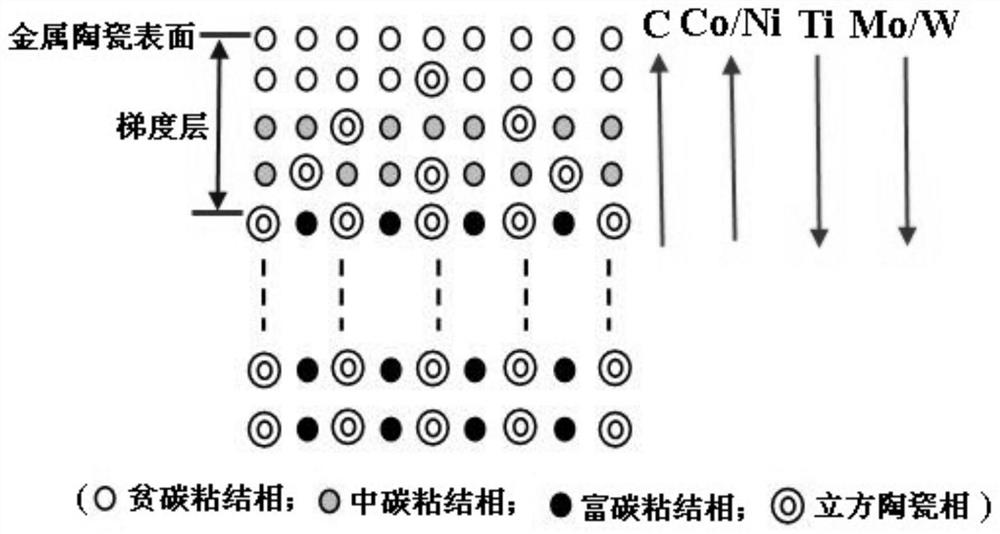

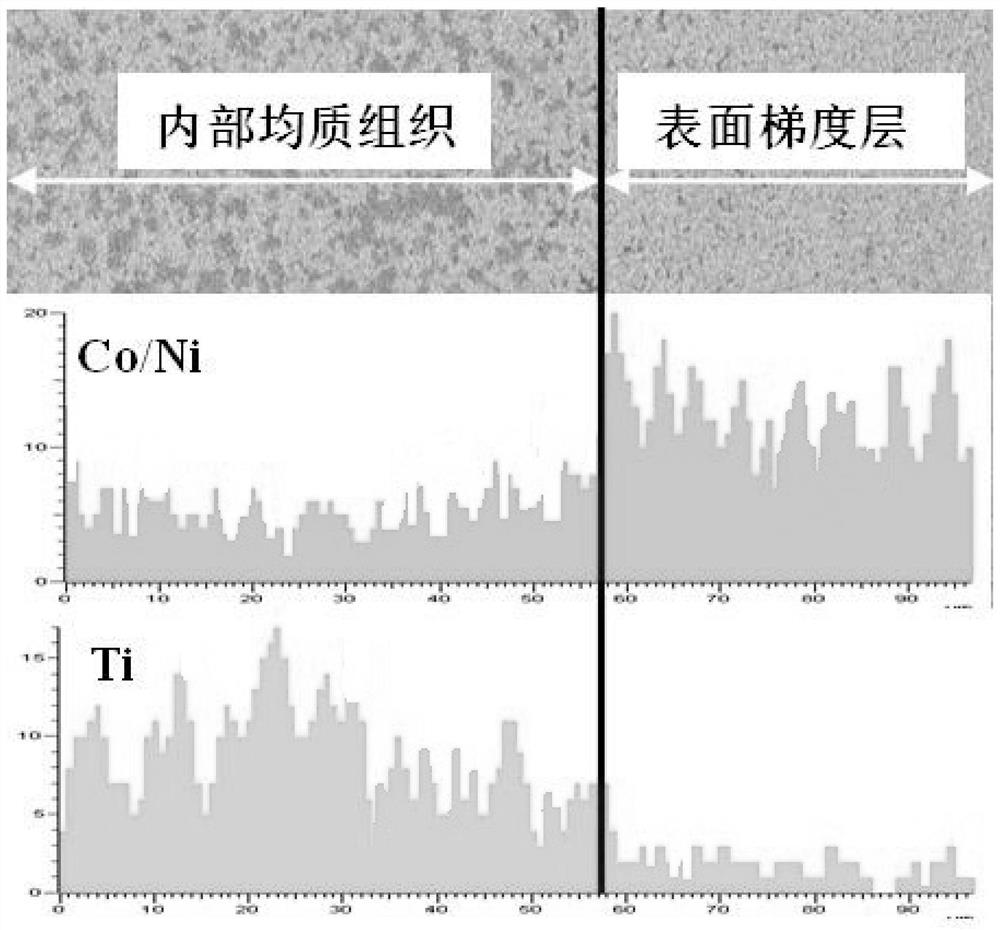

A gradient structure, titanium carbonitride technology, applied in the field of cermets, can solve problems such as low sintering efficiency, product structure deformation, gradient layer structure and low compositional continuity, achieve good strength and toughness, improve strength, carbon The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]A titanium carbonitride-based cermet with a metal-rich phase gradient structure, comprising the following raw materials in weight percentage: 10% nickel, 10% cobalt, 5% molybdenum carbide and 10% tungsten carbide, and the balance is TiC 0.7 N 0.3 .

[0028] The preparation method of the above-mentioned titanium carbonitride-based cermet with gradient metal-rich phase structure comprises the following steps:

[0029] (1) Weigh nickel, cobalt, molybdenum carbide, tungsten carbide and TiC respectively 0.7 N 0.3 , to obtain mixed powder after mixing evenly;

[0030] (2) The mixed powder obtained in step (1) is ball milled at a speed of 60r / min for 48h, the ball milling medium is No. 120 solvent gasoline, the addition is 0.8mL / g, and the grinding ball is a tungsten carbide alloy ball with a diameter of 6mm containing 8wt% cobalt , the ball-to-material ratio is 5:1, and 5wt% paraffin wax is added to the mixed powder; after being filtered through a 200-mesh screen, vacuum-d...

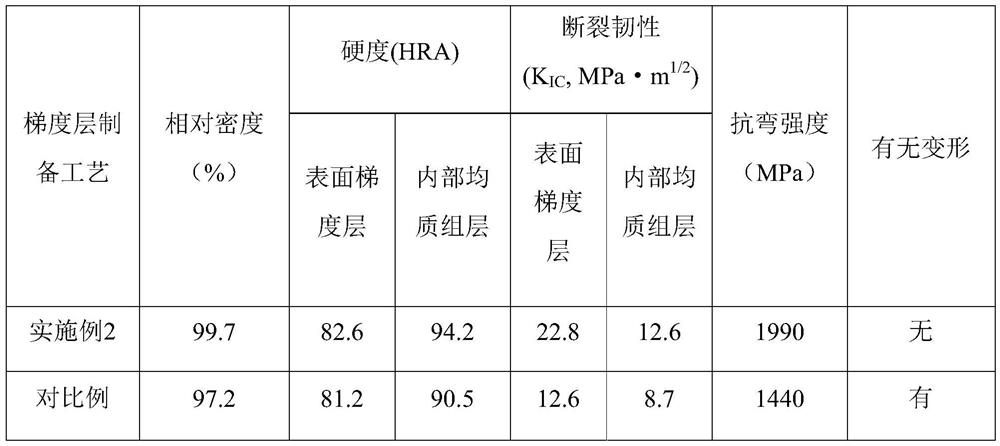

Embodiment 2

[0033] A titanium carbonitride-based cermet with a metal-rich phase gradient structure, comprising the following raw materials in weight percentage: 15% nickel, 15% cobalt, 8% molybdenum carbide and 15% tungsten carbide, and the balance is TiC 0.7 N 0.3 .

[0034] The preparation method of the above-mentioned titanium carbonitride-based cermet with gradient metal-rich phase structure comprises the following steps:

[0035] (1) Weigh nickel, cobalt, molybdenum carbide, tungsten carbide and TiC respectively 0.7 N 0.3 , to obtain mixed powder after mixing evenly;

[0036] (2) The mixed powder obtained in step (1) is ball-milled at a speed of 90r / min for 60h, the ball-milling medium is No. 120 solvent gasoline, the addition is 1.2mL / g, and the grinding ball is a tungsten carbide alloy ball with a diameter of 7mm containing 8wt% cobalt , the ball-to-material ratio is 10:1, and 8wt% paraffin wax is added to the mixed powder; after being filtered through a 300-mesh screen, vacuum...

Embodiment 3

[0039] A titanium carbonitride-based cermet with a gradient metal-rich phase structure, comprising the following raw materials in weight percent: 20% nickel, 20% cobalt, 10% molybdenum carbide and 20% tungsten carbide, and the balance is TiC 0.7 N 0.3 .

[0040] The preparation method of the above-mentioned titanium carbonitride-based cermet with gradient metal-rich phase structure comprises the following steps:

[0041] (1) Weigh nickel, cobalt, molybdenum carbide, tungsten carbide and TiC respectively 0.7 N 0.3 , to obtain mixed powder after mixing evenly;

[0042] (2) The mixed powder obtained in step (1) is ball milled at a speed of 120r / min for 72h, the ball milling medium is No. 120 solvent gasoline, the addition is 1.5mL / g, and the grinding ball is a tungsten carbide alloy ball with a diameter of 8mm containing 8wt% cobalt , the ball-to-material ratio is 15:1, and 10wt% paraffin wax is added to the mixed powder; after being filtered through a 400-mesh screen, vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com