Preparation of phenolic resin photocatalyst and sterilization and disinfection method thereof

A technology of photocatalysts and phenolic resins, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as high cost, insufficient safety and reliability, and reach the price Low, good bactericidal performance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

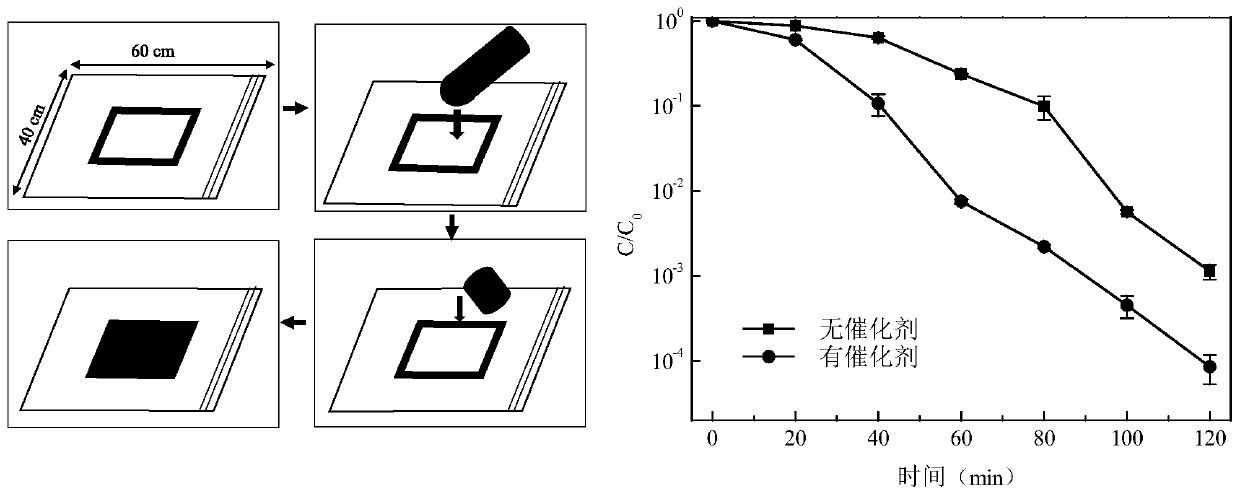

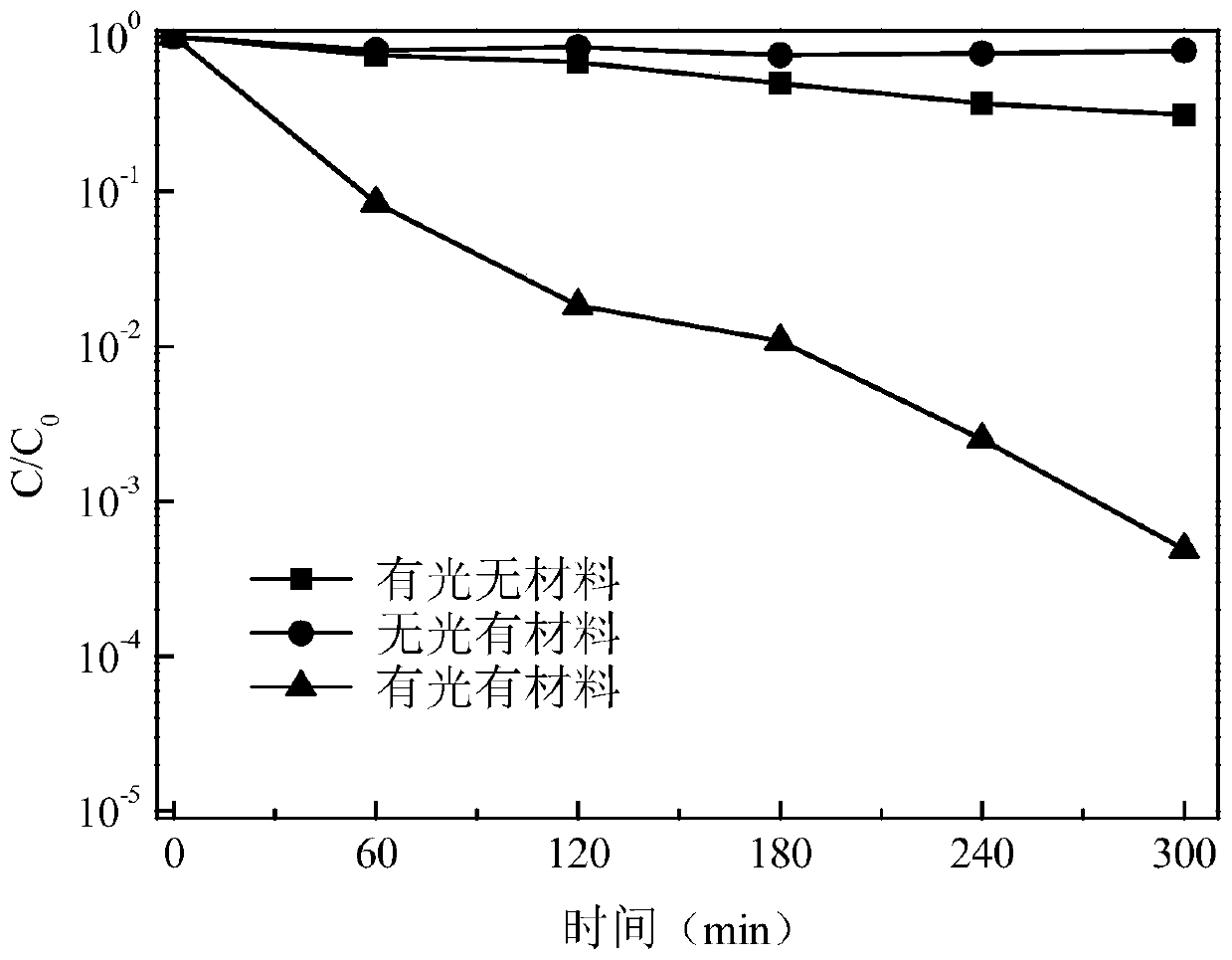

[0045] The initial concentration of E. coli in the 50ml reaction system was 10 6 CFU / mL, the degradation solution is sterile water, the light source is LED white light, and the light intensity is 40mW / cm 2 , the concentration of photocatalyst is 1mg / mL, the inactivation efficiency of E. coli after 5 hours of photocatalytic reaction is 99.95%; if no light is added and only photocatalyst is added, under the same conditions, the inactivation efficiency of E. coli is only 20%. It can be considered that there is no change within the error range; if only light is added and no photocatalyst is added, under the same conditions, the inactivation efficiency of Escherichia coli is about 60%. The corresponding photocatalytic sterilization effect diagram is as follows: figure 2 shown.

Embodiment 2

[0047] The inactivation efficiency of Escherichia coli under different light intensities was compared. The initial concentration of E. coli in the 50ml reaction system was 106 CFU / mL, the degradation solution is sterile water, the light source is LED white light, and the light intensity is changed to 20, 40, 60, 80mW / cm 2 , the concentration of photocatalyst is 1mg / mL, the inactivation efficiency of Escherichia coli after photocatalytic reaction for 5h is 99.3%, 99.95%, 99.96% and 99.996%, respectively, and the proportion of photolytic sterilization is 0%, 40%, 60% % and 99.1%.

Embodiment 3

[0049] The inactivation efficiency of Escherichia coli under different catalyst dosage conditions was compared. The initial concentration of E. coli in the 50ml reaction system was 10 6 CFU / mL, the degradation solution is sterile water, the light source is LED white light, and the light intensity is 40mW / cm 2 , changing the concentration of photocatalyst to 0.25, 0.5, 1.0, 1.5, 2.0mg / mL respectively, the inactivation efficiency of Escherichia coli after photocatalytic reaction for 5h was 98.6%, 99.2%, 99.9%, 99.996% and 99.997%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com