Self-cleaning amphiphobic coating for degrading NO and preparation method of self-cleaning amphiphobic coating

A kind of sparse coating and self-cleaning technology, which is applied in coatings, separation methods, chemical instruments and methods, etc., can solve the problems of reducing the durability of super-amphiphobic coatings, losing super-amphiphobic properties, and being easy to damage, and achieving improved UV stability, excellent photocatalytic activity and adsorption effect, improved anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

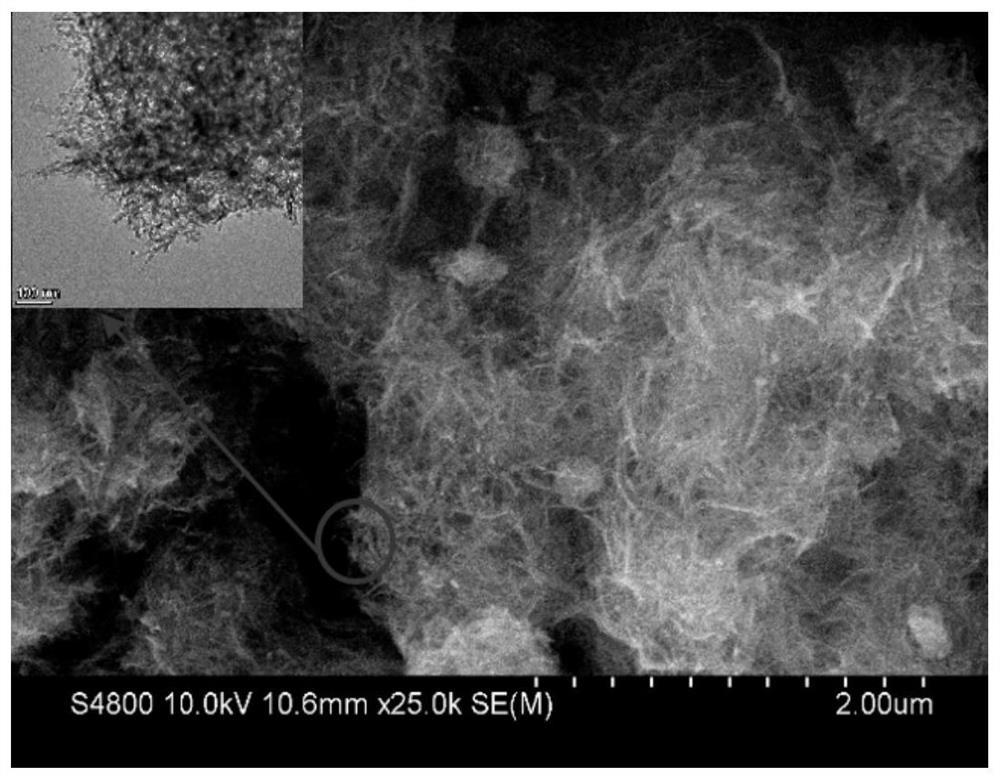

[0039] A method for preparing a self-cleaning amphobic coating for degrading NO, the specific steps are as follows:

[0040] Step 1: In parts by weight, 7 parts of P25 nano-titanium dioxide were added to 70 parts of 10mol / L sodium hydroxide solution, and stirred for 2 hours to obtain a suspension;

[0041] Step 2: Add the suspension into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 150°C for 48 hours to obtain a hydrothermal product;

[0042] Step 3: Wash the hydrothermal product 5-6 times with dilute hydrochloric acid, adjust the pH to 1-2, and stir for 24 hours;

[0043]Step 4: filter the precipitate, wash with deionized water until neutral, add absolute ethanol to disperse for 24 hours, and obtain a suspension;

[0044] Step 5: Suction filter the suspension in step 4, and dry at 110°C to constant weight to obtain titanium dioxide nanotubes;

[0045] Step 6: Disperse 0.1 part of epoxy resin (E44) in 18 parts of absolute ethanol, stir until dissolv...

Embodiment 2

[0051] A method for preparing a self-cleaning amphobic coating for degrading NO, the specific steps are as follows:

[0052] Step 1: In parts by weight, 10 parts of P25 nano-titanium dioxide were added to 70 parts of 10mol / L sodium hydroxide solution, and stirred for 2 hours to obtain a suspension;

[0053] Step 2: Add the suspension into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 150°C for 48 hours;

[0054] Step 3: Wash the hydrothermal product 5-6 times with dilute hydrochloric acid, adjust the pH to 1-2, and stir for 24 hours;

[0055] Step 4: Filter the precipitate generated in step 3, wash with deionized water until neutral, add absolute ethanol to disperse for 24 hours, and obtain a suspension;

[0056] Step 5: Suction filter the suspension prepared in Step 4, and dry at 110°C to constant weight to obtain titanium dioxide nanotubes;

[0057] Step 6: Disperse 0.4 parts of epoxy resin (E44) in 18 parts of absolute ethanol, stir until dissolve...

Embodiment 3

[0063] A method for preparing a self-cleaning amphobic coating for degrading NO, the specific steps are as follows:

[0064] Step 1: In parts by weight, 12 parts of P25 nano-titanium dioxide were added to 70 parts of 10mol / L sodium hydroxide solution, and stirred for 2 hours to obtain a suspension;

[0065] Step 2: Add the suspension into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 150°C for 48 hours;

[0066] Step 3: Wash the hydrothermal product 5-6 times with dilute hydrochloric acid, adjust the pH to 1-2, and stir for 24 hours;

[0067] Step 4: Filter the precipitate generated in step 3, wash with deionized water until neutral, add absolute ethanol to disperse for 24 hours, and obtain a suspension;

[0068] Step 5: Suction filter the suspension in step 4, and dry at 110°C to constant weight to obtain titanium dioxide nanotubes;

[0069] Step 6: Disperse 0.7 parts of epoxy resin (E44) in 18 parts of absolute ethanol, stir until dissolved, add 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com