Continuous production device and process for chlorinated fatty acid methyl ester

A technology for chlorinated fatty acid methyl esters and fatty acid methyl esters is applied in the field of continuous production devices of chlorinated fatty acid methyl esters, and can solve the problems of unfavorable chlorinated fatty acid methyl esters product stability and quality maintenance, reaction temperature product chromaticity increase, The acid value and chromaticity of the product are increased to achieve the effect of reducing costs, reducing energy consumption, and improving the degree of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

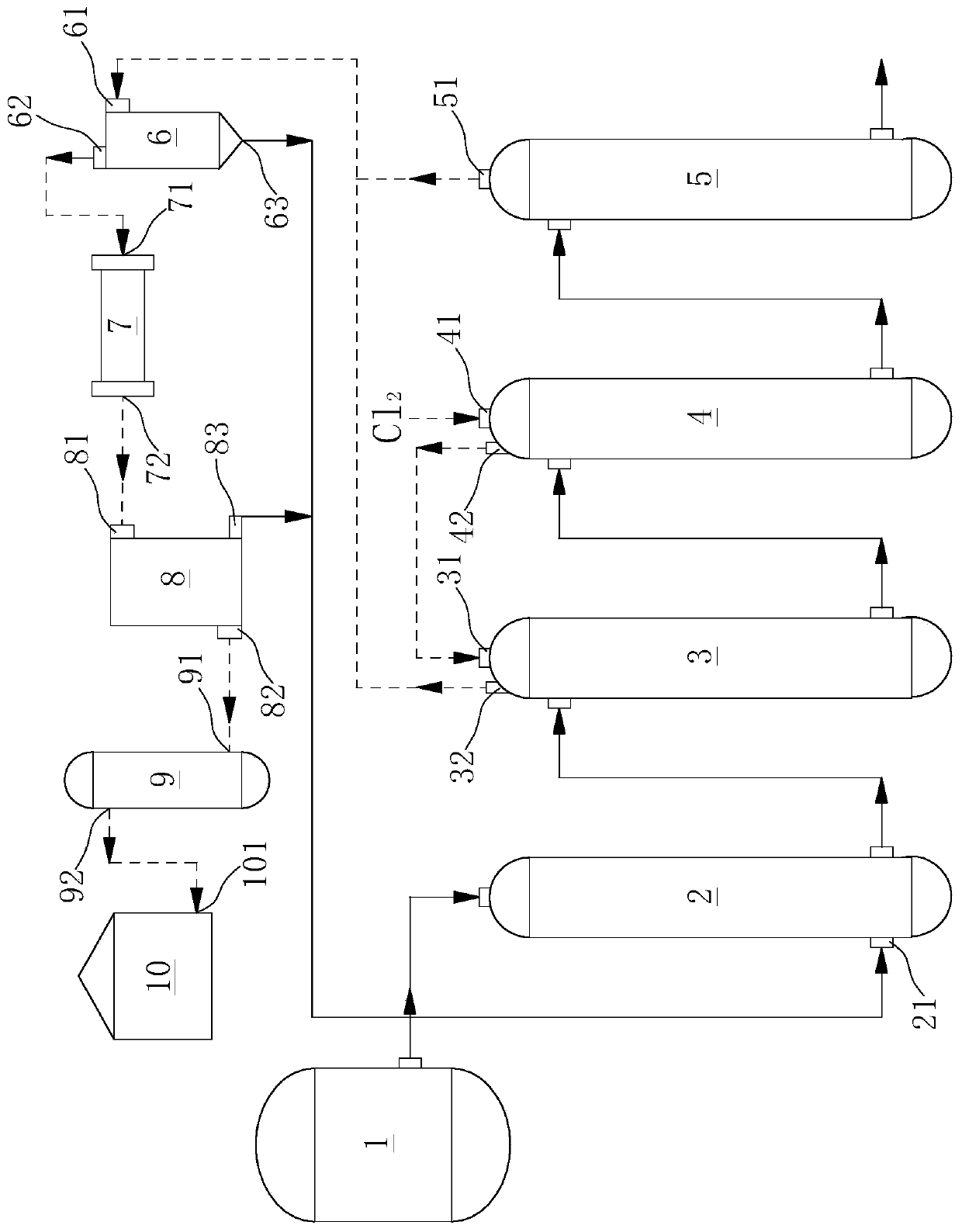

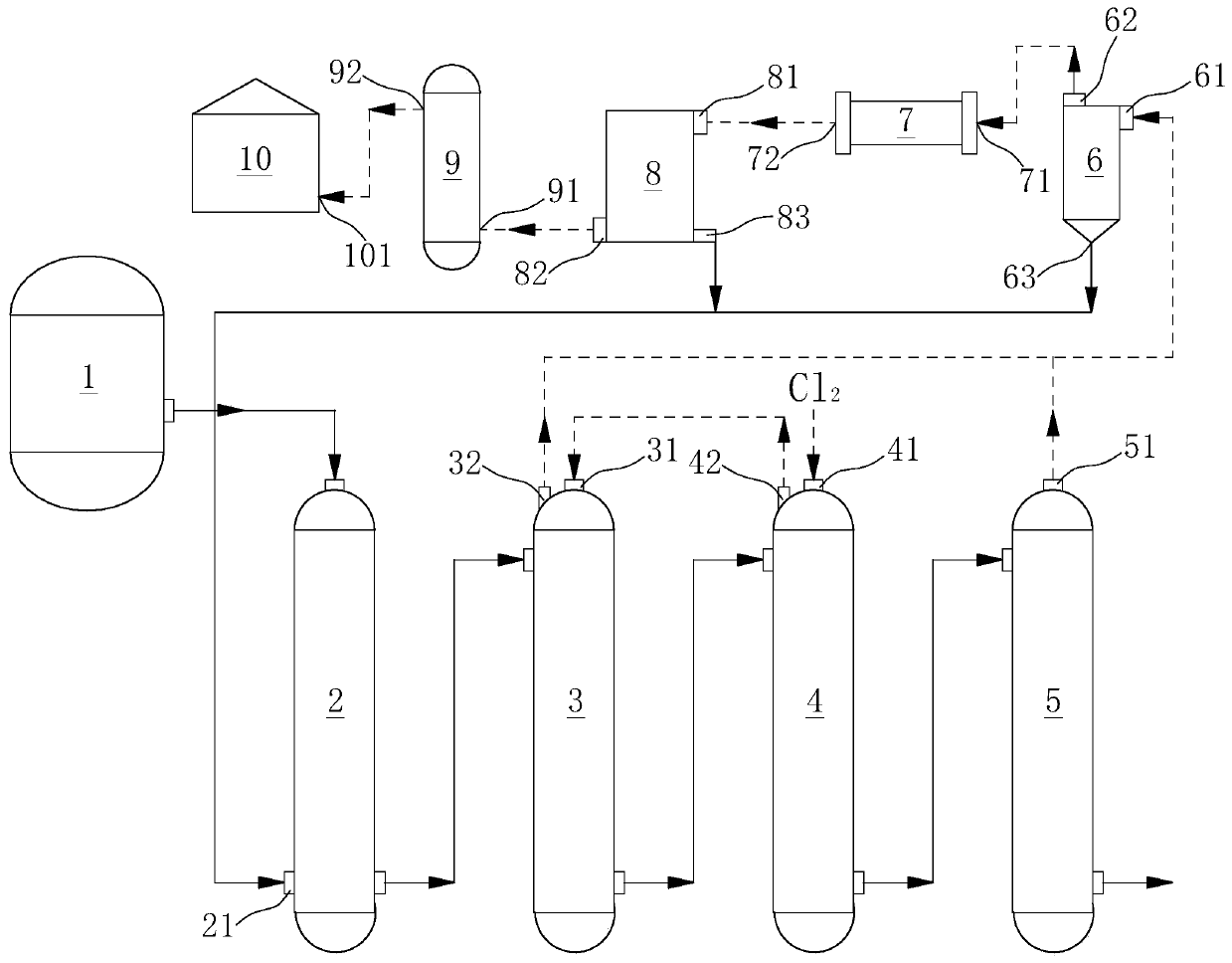

[0063] (1) the fatty acid methyl ester that iodine value is 28, color number is 20 enters the material inlet of absorption tower 2 through the material outlet in raw material storage tank 1;

[0064] (2) the fatty acid methyl ester from the material inlet of absorption tower 2 and the material (fatty acid methyl ester and chlorinated product thereof) from material replenishment inlet 21 enter absorption tower 2 and discharge by overflow after mixing, and enter by the material outlet of absorption tower 2 The material inlet of the primary reaction tower 3;

[0065] (3) fatty acid methyl ester from the material inlet of primary reaction tower 3 and the hydrogen chloride tail gas from the first air inlet 31 enter primary reaction tower 3, under aluminum trichloride catalyst and 45 ℃ of conditions, fatty acid methyl ester and Hydrogen chloride carries out addition reaction, judges the degree of material reaction according to sampling measurement specific gravity, the chlorinated f...

Embodiment 2

[0076] (1) the fatty acid methyl ester that iodine value is 30, color number is 30 enters the material inlet of absorption tower 2 through the material outlet in raw material storage tank 1;

[0077] (2) the fatty acid methyl ester from the material inlet of absorption tower 2 and the material (fatty acid methyl ester and chlorinated product thereof) from material replenishment inlet 21 enter absorption tower 2 and discharge by overflow after mixing, and enter by the material outlet of absorption tower 2 The material inlet of the primary reaction tower 3;

[0078] (3) fatty acid methyl ester from the material inlet of primary reaction tower 3 and the hydrogen chloride tail gas from the first gas inlet 31 enter primary reaction tower 3, under aluminum trichloride catalyst and 60 ℃ of conditions, fatty acid methyl ester and Hydrogen chloride carries out addition reaction, judges the degree of material reaction according to sampling measurement specific gravity, the chlorinated f...

Embodiment 3

[0089] (1) the fatty acid methyl ester that iodine value is 26, color number is 25 enters the material inlet of absorption tower 2 through the material outlet in raw material storage tank 1;

[0090] (2) the fatty acid methyl ester from the material inlet of absorption tower 2 and the material (fatty acid methyl ester and chlorinated product thereof) from material replenishment inlet 21 enter absorption tower 2 and discharge by overflow after mixing, and enter by the material outlet of absorption tower 2 The material inlet of the primary reaction tower 3;

[0091] (3) fatty acid methyl ester from the material inlet of primary reaction tower 3 and the hydrogen chloride tail gas from the first air inlet 31 enter primary reaction tower 3, under aluminum trichloride catalyst and 40 ℃ of conditions, fatty acid methyl ester and Hydrogen chloride carries out addition reaction, judges the degree of material reaction according to sampling measurement specific gravity, the chlorinated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com