A petal-shaped microsphere molybdenum disulfide composite carbon material loaded PD metal catalyst and preparation method thereof

A metal catalyst and composite carbon technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of catalyst poisoning, failure activity, occupation, environmental pollution, etc., and achieve the effect of low equipment requirements, simple process, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

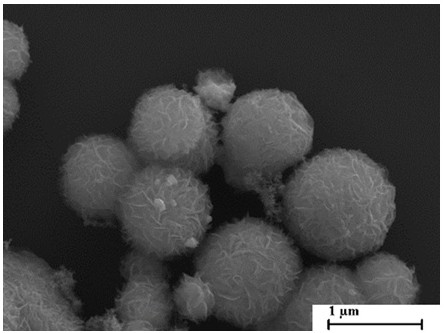

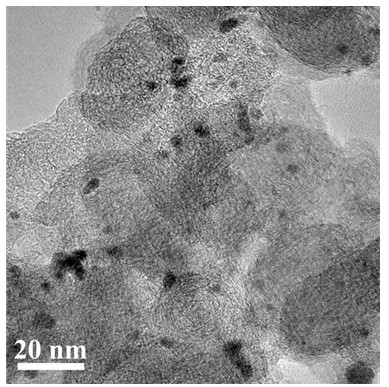

[0022] A petal-shaped microsphere MoS 2 The preparation method of composite carbon material supported Pd metal catalyst, concrete steps are as follows:

[0023] (1) Add 0.5g of XC-72 carbon black into 40mL of deionized water to disperse evenly, add 0.1g of sodium molybdate and 0.1g of thiourea into the above solution, ultrasonicate for 30min, stir for 30min, and then carry out 6h pretreatment in 80℃ water bath After treatment, the solution was transferred to a microwave reactor, microwaved at 200 °C for 5 min, and then dried by centrifugation to obtain MoS 2 Composite carbon materials;

[0024] (2) The MoS obtained in step (1) 2 The composite carbon material was treated at 500 °C for 4 h in a nitrogen atmosphere to obtain MoS 2 / C;

[0025] (3) The MoS in step (2) 2 / C is poured into 40mL of 5mmol / L chloropalladium acid solution according to the molar ratio of molar ratio of platinum and palladium elements, then ultrasonic treatment for 1h and stirring for 1h to form a un...

Embodiment 2

[0028] A petal-shaped microsphere MoS 2 The preparation method of composite carbon material supported Pd metal catalyst, concrete steps are as follows:

[0029] (1) Add 0.5g of XC-72 carbon black into 40 mL of deionized water to disperse evenly, add 0.1g of sodium molybdate and 0.1g of thiourea into the above solution, ultrasonicate for 30min, stir for 30min, and then carry out 80℃ water bath for 6h Pretreatment, then transfer the solution to a microwave reactor, microwave treatment at 200 ° C for 8 min, and then perform centrifugal drying to obtain MoS 2 Composite carbon materials;

[0030] (2) The MoS obtained in step (1) 2 Composite carbon materials in N 2 Treat at 550°C for 3 hours in the atmosphere to get MoS 2 / C;

[0031] (3) The MoS in step (2) 2 / C is poured into 40mL of 5mmol / L chloropalladium acid solution according to the molar ratio of molar ratio of platinum and palladium elements, then ultrasonic treatment for 1h and stirring for 1h to form a uniform suspe...

Embodiment 3

[0034] A petal-shaped microsphere MoS 2 The preparation method of composite carbon material supported Pd metal catalyst, concrete steps are as follows:

[0035] (1) Add 0.5g of XC-72 carbon black into 40 mL of deionized water to disperse evenly, add 0.1g of sodium molybdate and 0.1g of thiourea into the above solution, ultrasonicate for 30min, stir for 30min, and then carry out 80℃ water bath for 6h Pretreatment, then transfer the solution to a microwave reactor, microwave treatment at 200 ° C for 10 min, and then perform centrifugal drying to obtain MoS 2 Composite carbon materials;

[0036] (2) The MoS obtained in step (1) 2 Composite carbon materials in N 2 Treat at 600°C for 2 hours in the atmosphere to get MoS 2 / C;

[0037] (3) The MoS in step (2) 2 / C is poured into 40mL of 5mmol / L chloropalladium acid solution according to the molar ratio of molar ratio of platinum and palladium elements, then ultrasonic treatment for 1h and stirring for 1h to form a uniform susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com