Ultrasonic-assisted selective laser melting device for TiC/TiAl/Nb micro-laminated composite material

A selective laser melting, ultrasonic-assisted technology, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problem of materials that cannot meet the needs of use, cannot be produced with good performance, and cannot overcome the excessive spheroidization of layer spacing. and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

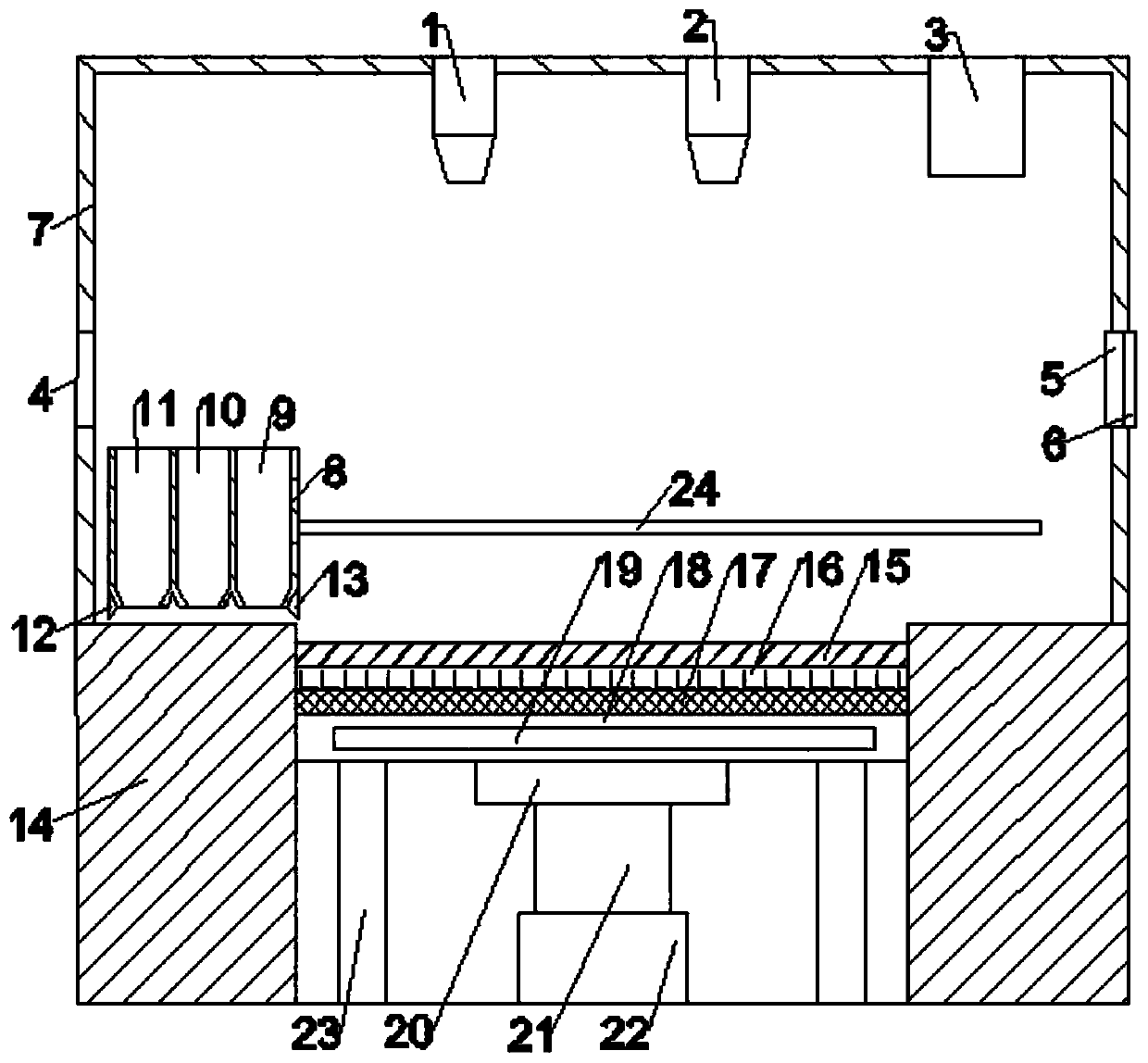

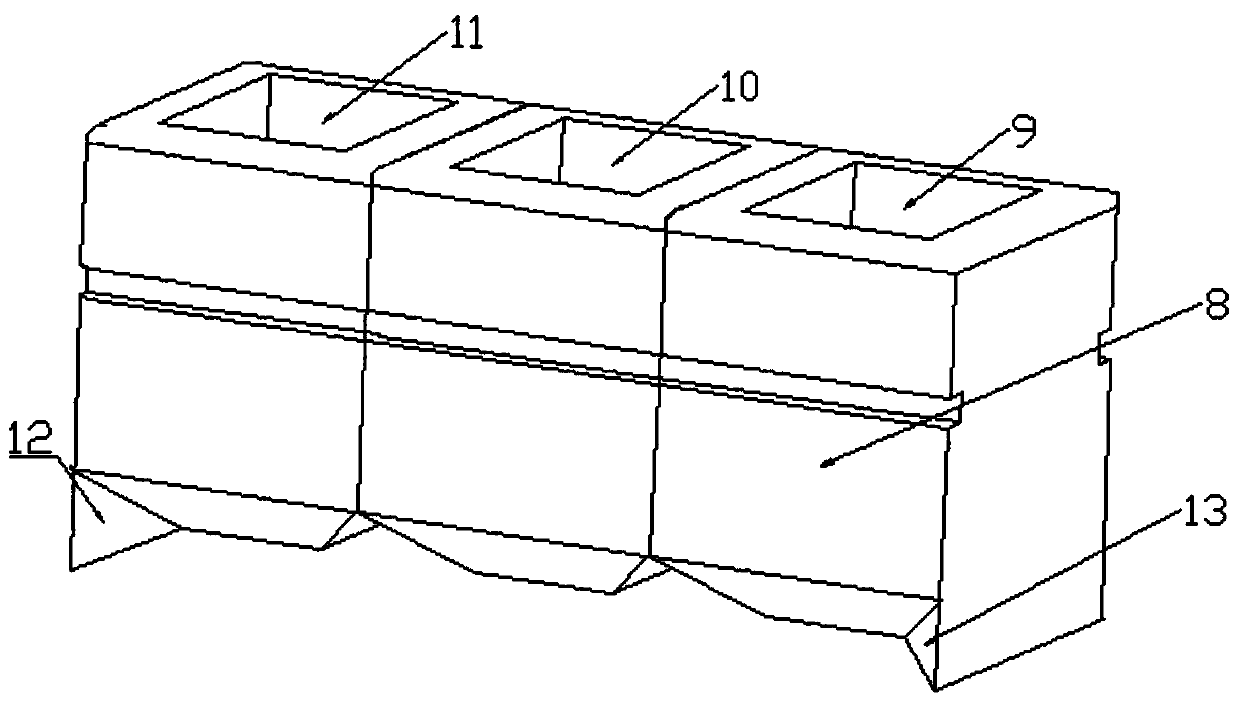

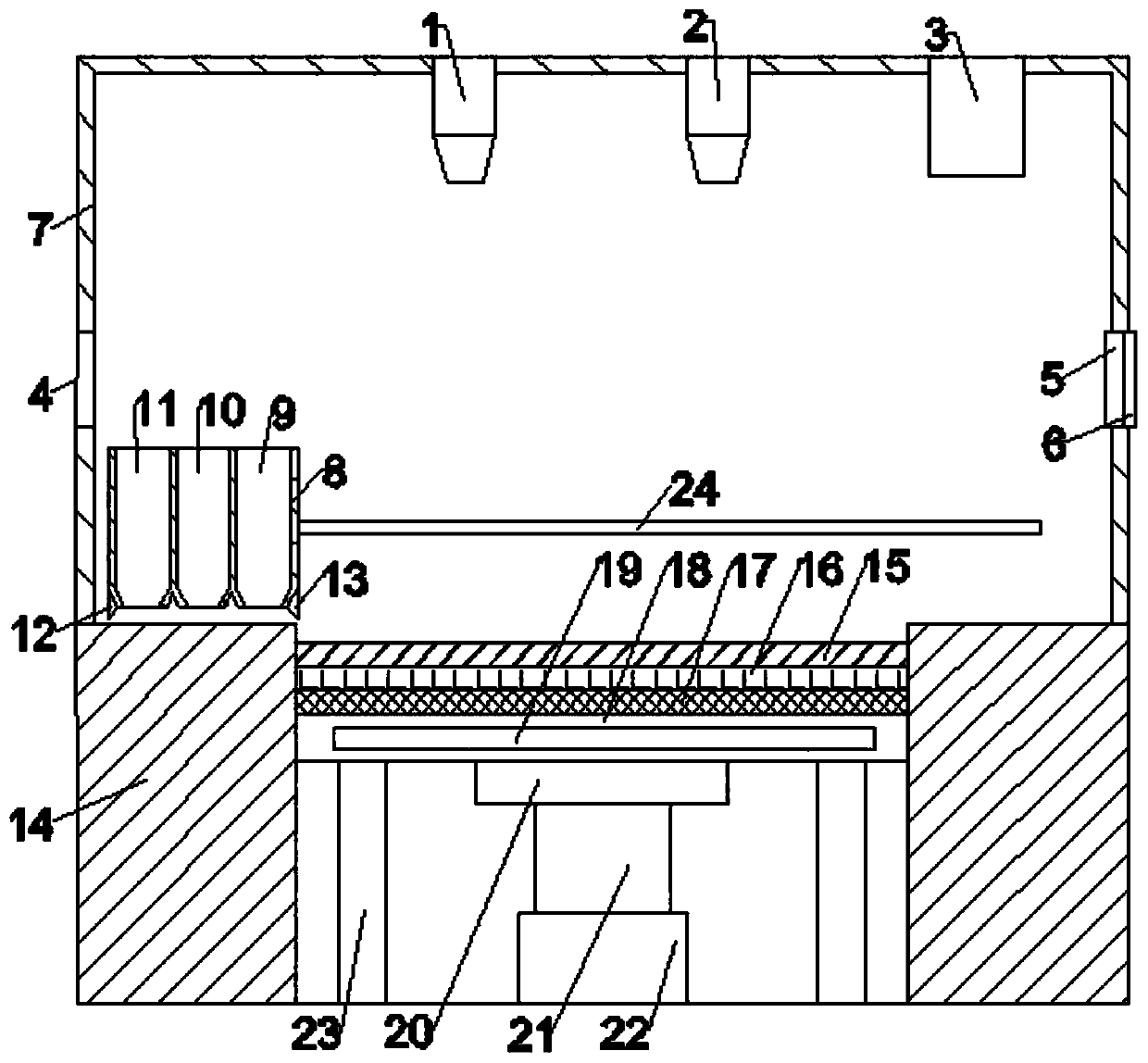

[0040] Import the three-dimensional model of the TiC / TiAl / Nb micro-laminated composite parts to be manufactured into the computer, perform layered slicing of the model and scan path planning, and input the parameters required in the forming process. Put the dried TiC powder, TiAl powder and Nb powder into the TiC chamber, TiAl chamber and Nb chamber respectively. The high-purity argon is dried through the inlet drier, heated by the inlet heater and passed into the forming chamber. The substrate is preheated by the substrate preheater of the substrate, the powder is preheated by the material preheater of the powder room, the heating function of the forming room is turned on, and the heat preservation of the forming room is carried out.

[0041] Drive the substrate moving rod through the motor screw to adjust the height of the substrate to a position lower than the thickness of the first layer of powder on the height platform, and use the external motor to move the powder chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com