Low-GI (glycemic index) highland barley cereal premixed flour product as well as making process and application thereof

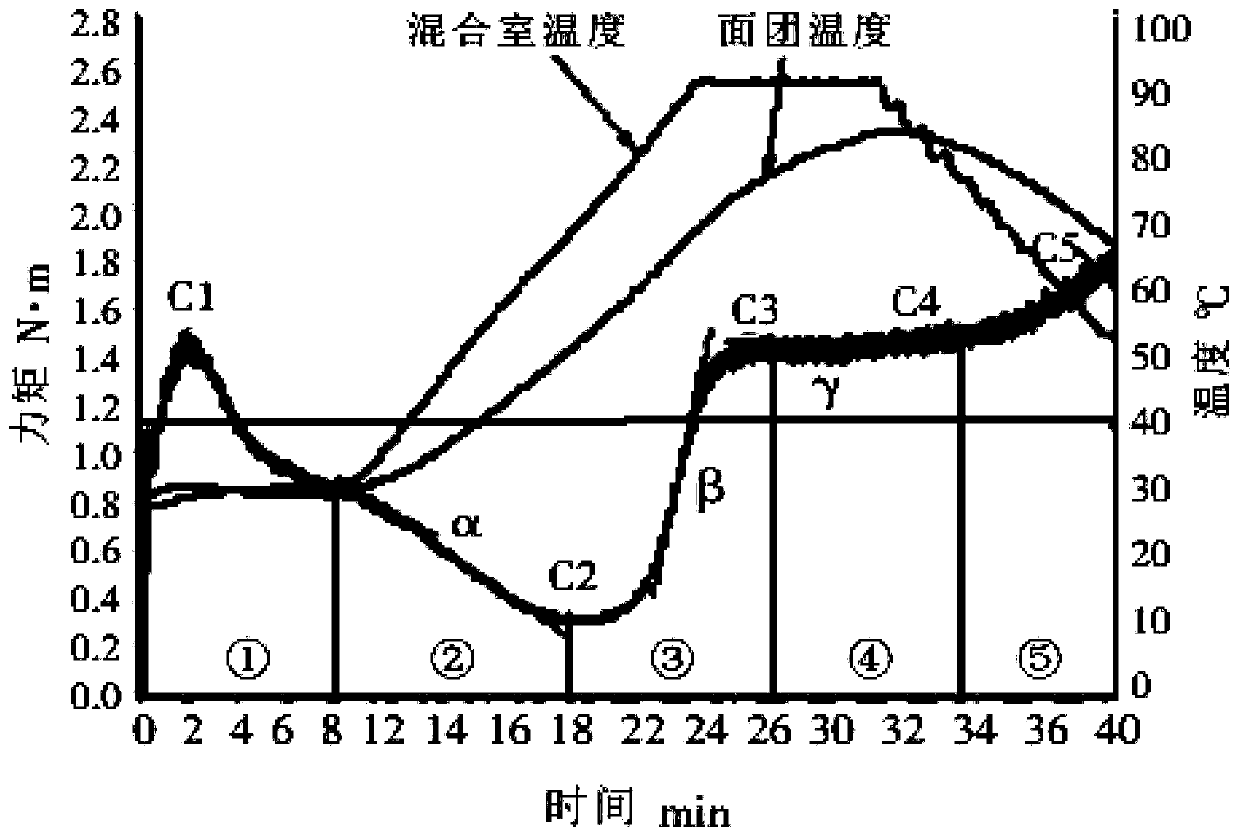

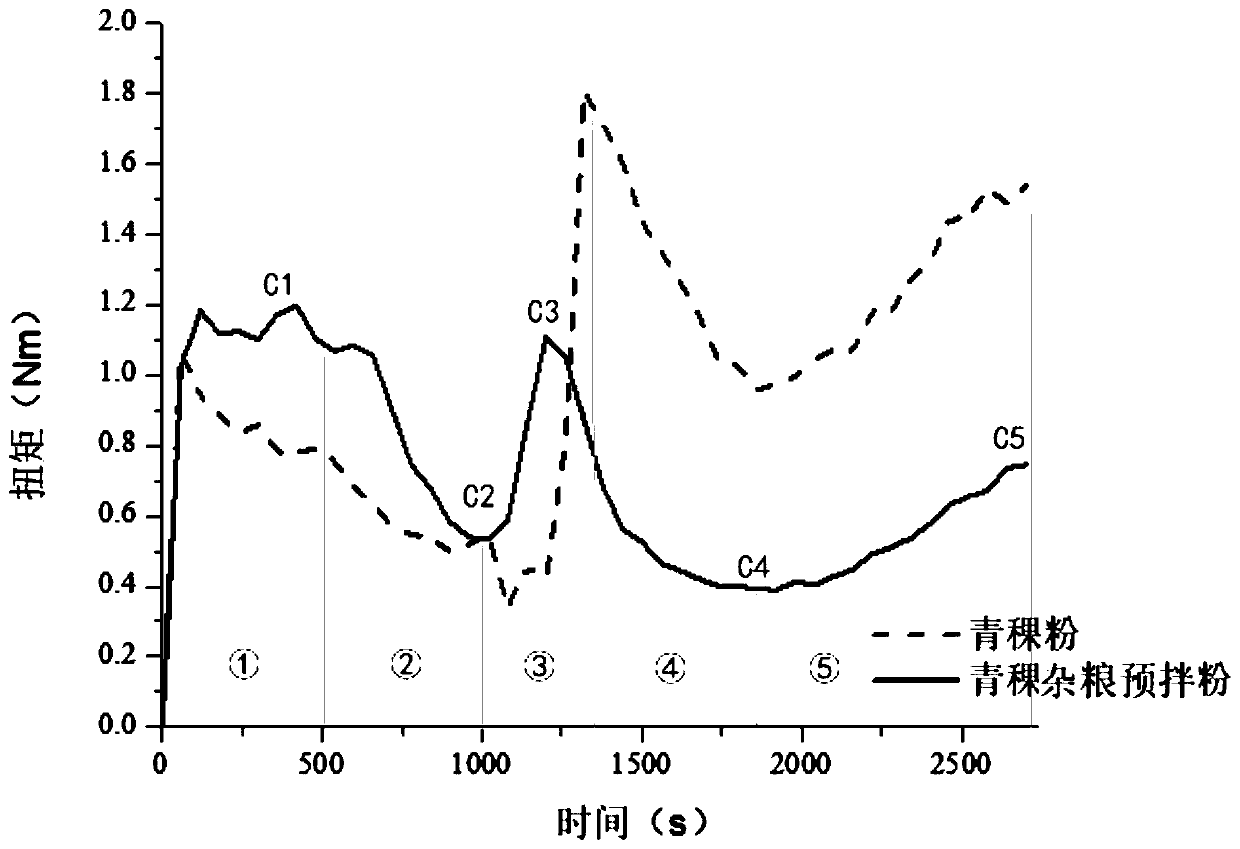

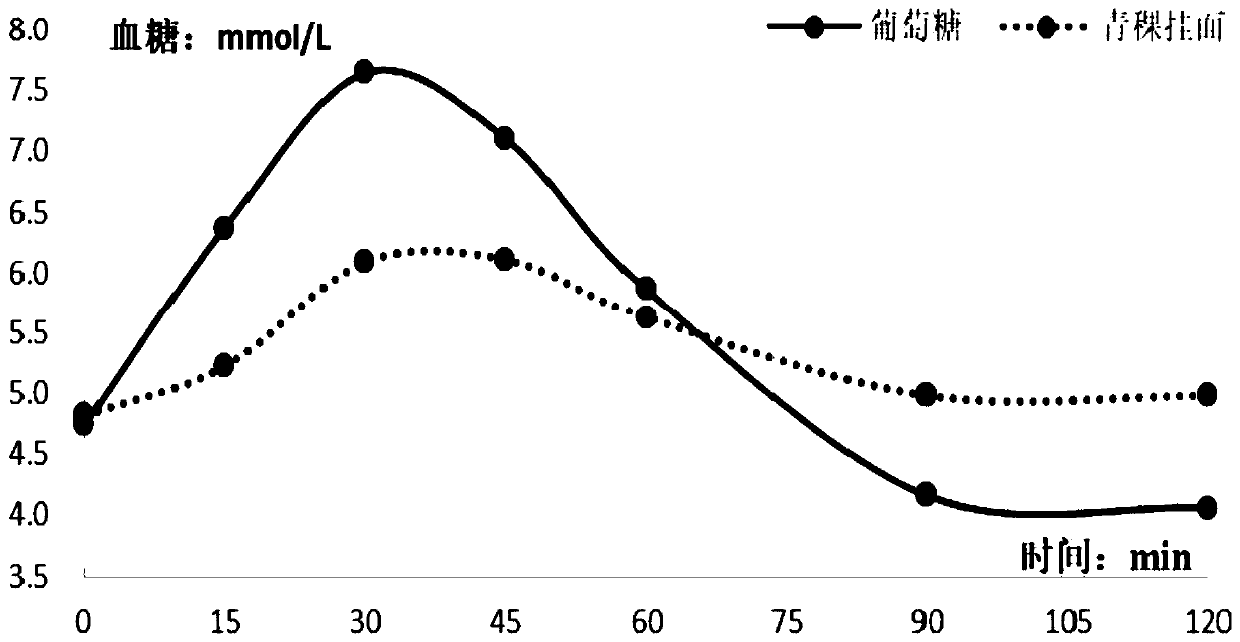

A technology for ready-mixed flour and highland barley flour, which is applied to low-GI highland barley miscellaneous grain ready-mixed powder products and its preparation process and application field, can solve the problems of easy aging of highland barley starch, poor cooking properties, and high content of high-viscosity β-glucan , to achieve the effect of delaying the increase of blood sugar concentration and insulin level, good food quality and nutritional value, and stable powder structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment provides a kind of premixed highland barley miscellaneous grains, the formula is as follows:

[0069]

[0070]

[0071] The preparation method is as follows:

[0072] (1) Mix HF compound enzyme, soybean protein isolate and whole egg powder to obtain the first material;

[0073] (2) mixing gluten, potato starch and salt to obtain the second portion of material;

[0074] (3) mixing the whole highland barley powder, wheat flour, the first part and the second part to obtain the premixed highland barley powder;

[0075] Wherein, the whole highland barley powder is obtained by crushing yellow highland barley grains and passing through a 100-mesh sieve;

[0076] Wheat flour was purchased from Qinghai Xindingxiang Grain and Oil Co., Ltd., F0 flour;

[0077] Gluten powder was purchased from Zhengzhou Yuxiang Food Development Co., Ltd., the model is "Midaner";

[0078] Soy protein isolate was purchased from Shucai Trading (Shanghai) Co., Ltd., the model ...

Embodiment 2

[0084] This embodiment provides a kind of premixed highland barley miscellaneous grains, the formula is as follows:

[0085]

[0086]

[0087] Raw material source and preparation method are identical with embodiment 1.

Embodiment 3

[0089] This embodiment provides a kind of premixed highland barley miscellaneous grains, the formula is as follows:

[0090]

[0091] Raw material source and preparation method are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com