Low-carbon martensitic stainless steel for valve box and smelting method thereof

A low-carbon martensite and smelting method technology, applied in the field of stainless steel smelting, can solve the problems of high production raw material cost, long smelting process, and inability to directly reduce, so as to avoid returning to refining to adjust carbon increase, avoid returning to refining to adjust, and reduce The effect of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

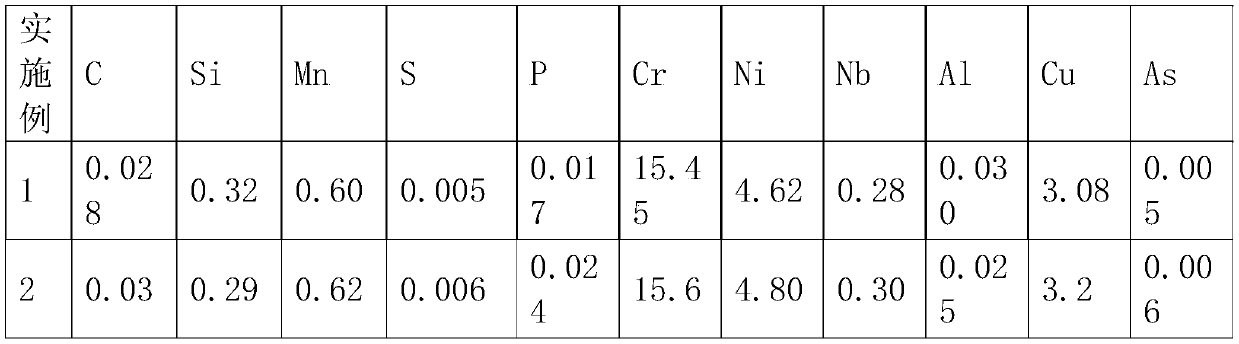

Examples

Embodiment 1

[0022] Example 1: A low-carbon martensitic stainless steel for a valve box, its technological process is: batching-induction furnace melting material head, steel shavings-deoxidation reduction microalloying in refining furnace-slag removal-VOD vacuum oxygen blowing decarburization- Reduction under vacuum conditions - vacuum degassing - die casting steel - annealing or hot delivery.

[0023] Its composition is as follows: C≤0.05%, Si:0.20-0.50%, Mn:0.30-0.70%, P≤0.025%, S≤0.010%, Ni:3.00-5.00%, Cr:15.0-17.5%, Cu:3.00 -5.00%, Nb:0.15-0.45%, Al≤0.040%.

[0024] A method for smelting low-carbon martensitic stainless steel for valve boxes, using batching-induction furnace melting head, steel shavings-deoxidation reduction microalloying in refining furnace-slag removal-VOD vacuum blowing oxygen decarburization-reduction under vacuum conditions- The technological process of vacuum degassing-die casting and pouring steel; specifically includes the following steps:

[0025] Step SO1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com