Method for preparing nano-MoS2-Al2O3 composite rolling lubricant by utilizing dopamine polymerization

A mos2-al2o3, compound rolling technology, applied in the field of lubrication, can solve the problems of reducing anti-wear and anti-friction performance, and achieve the effect of reducing rolling force and friction coefficient, improving surface quality and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

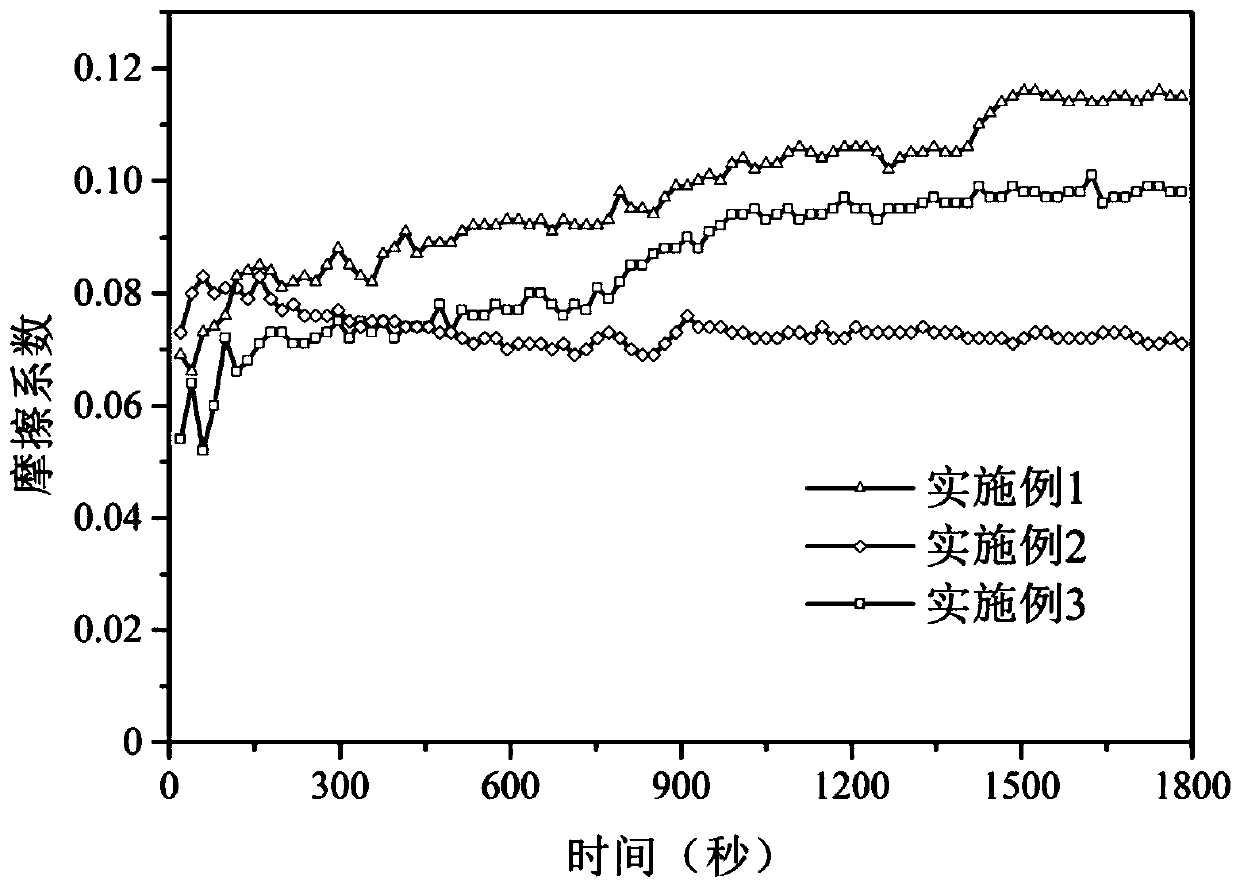

Embodiment 1

[0028] The main components and mass fraction of embodiment 1 are as follows:

[0029] serial number component name Mass fraction / wt.% 1 Molybdenum disulfide-alumina nanoparticles 1 2 Glycerol 5 3 Triethanolamine 6 4 Hexametaphosphate 0.4 5 Sodium dodecyl benzene sulfonate 0.8 6 Waterborne Borate 0.5 7 Defoamer 0.1 8 Deionized water 86.2

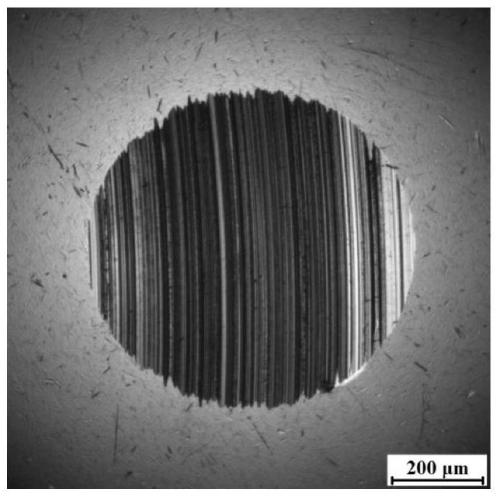

[0030] Add 2.0 g of polydopamine-modified molybdenum disulfide nanosheets and 100 g of ethylene glycol into the beaker, and after magnetic stirring for 5 min, gradually add 4.0 g of aluminum chloride hexahydrate and 10.0 g of polyethylene glycol 200, and continue at 900 r / min After stirring for 20 min, the beaker was placed in 40 kHz ultrasonic wave for 15 min. Then add 20g of sodium acetate, keep stirring at the above temperature and speed for 2 hours, transfer the obtained liquid to a high-temperature reactor, heat it to 180°C for hydrothermal reaction for 15 hours, a...

Embodiment 2

[0033] The main components and mass fraction of embodiment 2 are as follows:

[0034] serial number component name Mass fraction / wt.% 1 Molybdenum disulfide-alumina nanoparticles 3 2 Glycerol 3 3 Triethanolamine 5 4 Hexametaphosphate 1 5 Sodium dodecyl benzene sulfonate 2.2 6 Waterborne Borate 0.5 7 Defoamer 0.1 8 Deionized water 85.2

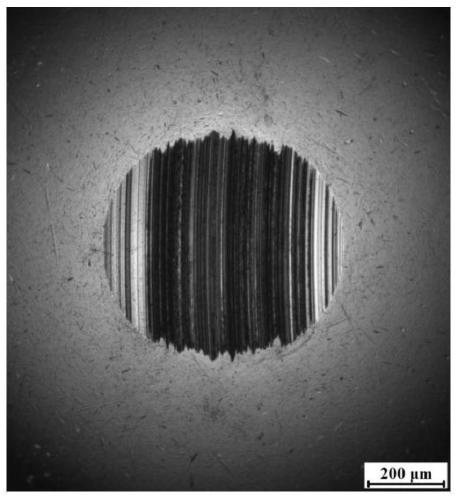

[0035]Add 2.0 g of polydopamine-modified molybdenum disulfide nanosheets and 100 g of ethylene glycol into the beaker, and after magnetic stirring for 5 min, gradually add 4.0 g of aluminum chloride hexahydrate and 8.0 g of polyethylene glycol 200, and continue at 900 r / min After stirring for 20 min, the beaker was placed in 40 kHz ultrasonic wave for 15 min. Then add 20g of sodium acetate, keep stirring at the above temperature and speed for 2 hours, transfer the obtained liquid to a high-temperature reactor, heat to 180°C for hydrothermal reaction for 15 hours, and cent...

Embodiment 3

[0038] The main components and mass fraction of embodiment 3 are as follows:

[0039] serial number component name Mass fraction / wt.% 1 Molybdenum disulfide-alumina nanoparticles 4 2 Glycerol 3 3 Triethanolamine 3 4 Hexametaphosphate 1.5 5 Sodium dodecyl benzene sulfonate 3.2 6 Waterborne Borate 0.5 7 Defoamer 0.1 8 Deionized water 84.7

[0040] Add 2.0 g of polydopamine-modified molybdenum disulfide nanosheets and 100 g of ethylene glycol into the beaker, and after magnetic stirring for 5 min, gradually add 6.0 g of aluminum chloride hexahydrate and 10.0 g of polyethylene glycol 200, and continue at 1000 r / min After stirring for 20 min, the beaker was placed in 40 kHz ultrasonic wave for 15 min. Then add 20g of sodium acetate, keep stirring at the above temperature and speed for 2 hours, transfer the obtained liquid to a high-temperature reactor, heat to 190°C for hydrothermal reaction for 15 hours, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com