Construction method of high-yield pantothenic-acid genetically engineered bacterium and bacterium strain

A technology of genetically engineered strains and genetically engineered bacteria, which is applied in the field of improving the production of pantothenic acid in genetically engineered bacteria and in the field of strains, which can solve problems such as insufficient final yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

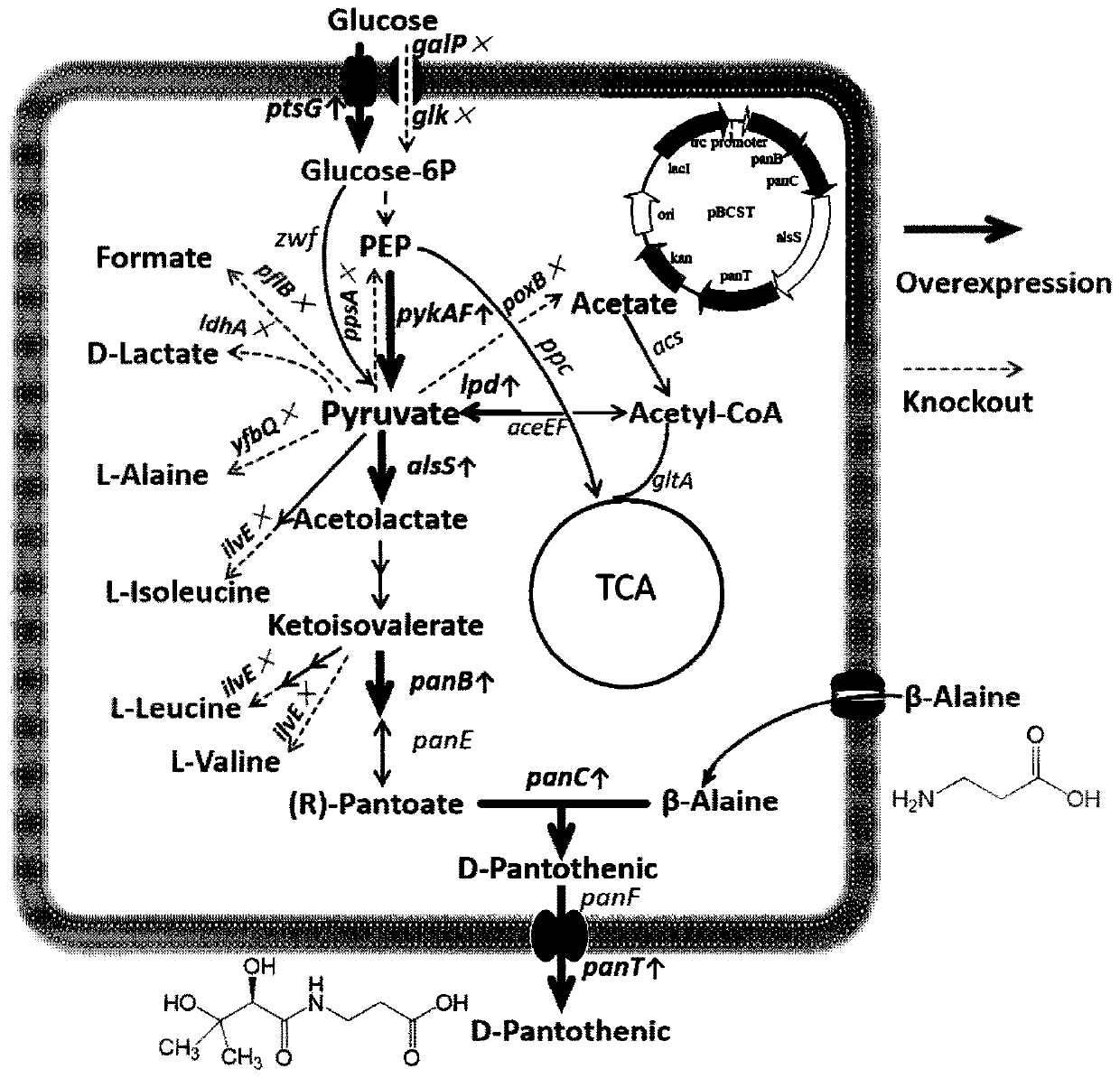

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1: Determination of D-pantothenic acid content in fermented liquid by HPLC method

[0083] The detection method is as follows:

[0084] Sample treatment: Take 1ml of fermentation broth and centrifuge to get the supernatant, dilute the supernatant with ultrapure water to an appropriate multiple, and keep the D-pantothenic acid content between 0.05g / L and 0.40g / L;

[0085] Chromatographic conditions: C 18 Column (250×4.6mm, particle size 5μm, Agilent Technologies Co., Santa Clara, CA, USA), detection wavelength: 200nm, column temperature: 30°C, flow rate: 0.9ml / min;

[0086] Mobile phase: acetonitrile / water / phosphoric acid: (50 / 949 / 1);

[0087] Data collection time: 23min.

Embodiment 2

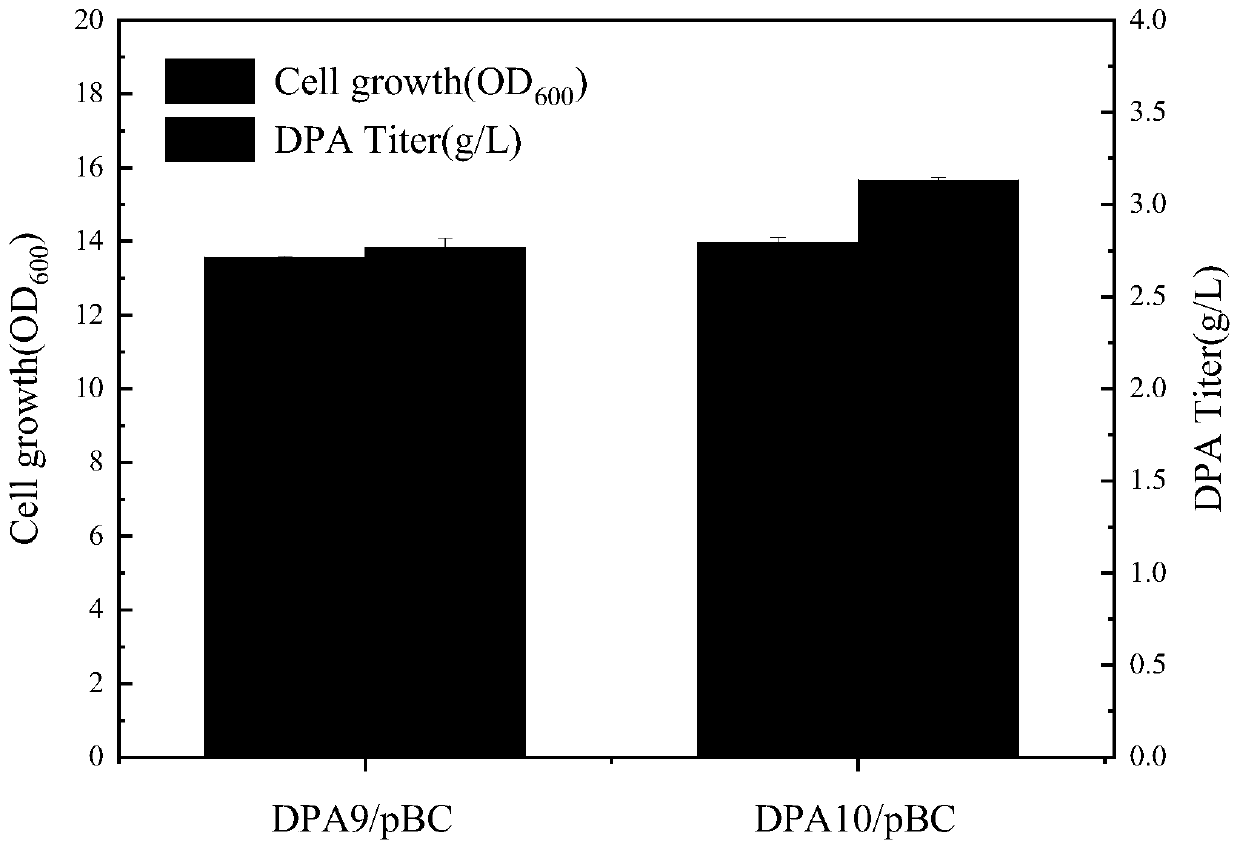

[0088] Embodiment 2: Construction and shake flask fermentation of strain DPA10 overexpressing lpd gene

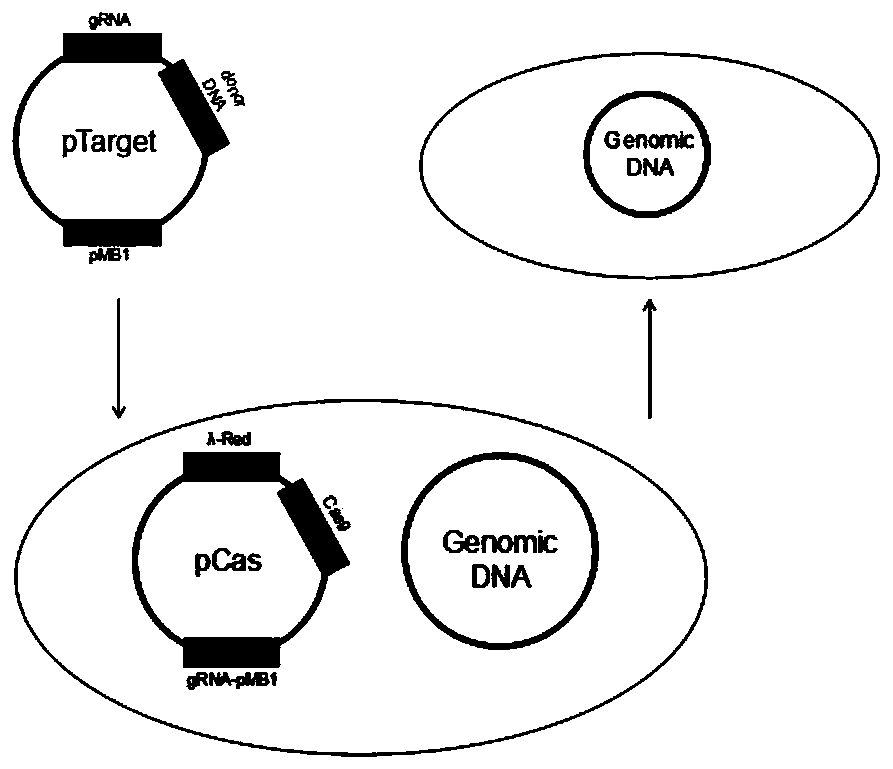

[0089] Using genetically engineered bacteria DPA9 (CCTCC NO: M 2018914) as the starting strain, using CRISPR-Cas9-mediated gene editing technology such as figure 1 (Yu Jiang et al.2015Multigene Editing in the Escherichiacoli Genome via the CRISPR-Cas9System.Applied Environmental Microbiology.81:2506-2514), with the Trc promoter derived from pTrc99A (nucleotide sequence shown in SEQ ID No.1 ), to replace the natural promoter of the lpd gene in the genome to enhance the expression intensity of the lpd gene.

[0090] (1) Construction of pTarget-panC plasmid: use pTarget F plasmid (Addgene Plasmid#62226) as a template, use pT-lpd F / pT-lpd R as primers for PCR amplification, and the obtained PCR product is digested by Dpn I at 37°C 3h, and then transformed into E.coli DH5αtransformation-competent medium, screened with spectinomycin (SD) plate, and sequenced to verify that the c...

Embodiment 3

[0099] Embodiment 3: Construction and shake flask fermentation of the strain DPA11 of knockout glk gene

[0100] (1) Construction of pTarget-glk plasmid: use pTarget F plasmid (Addgene Plasmid#62226) as a template, use pTarget-glk F / pTarget-glk R as primers for PCR amplification, and digest the PCR product with Dpn I at 37°C for 3 hours. Then transformed into E.coli DH5α-transformation competent cells, screened with spectizyme plate, and sequenced to verify that the correct pTarget-glk plasmid was obtained for subsequent connection with DonorDNA.

[0101] (2) Construction of the pTD-glk plasmid: using the E.coli W3110 genome as a template, pTD-glk P1, pTD-glk P2, pTD-glk P3 and pTD-glk P4 as primers, the construction steps are the same as in Example 2 (2), The pTD-glk plasmid was obtained.

[0102] (3) The pCas plasmid (Addgene Plasmid #62225) was introduced into the competent strain DPA10 obtained in Example 2, and the preparation method of the competent strain DPA10 was the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com