A kind of hollow black aluminum titanium oxide solar light absorbing material and its preparation method and application

A technology for absorbing materials and sunlight, applied in titanium oxide/hydroxide, chemical instruments and methods, titanium dioxide, etc., to achieve high-efficiency light absorption, high light-to-heat conversion efficiency, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1 hollow black aluminum titanium oxide solar absorption material sample 1 # Preparation

[0074] Tell 5G Tio 2 Powder, 3G aluminum powder, 7.14g alcl 3 The powder was ground for 30 min with a mortar. Then, poured into the nickel crucible, placed the nickel crucible in the tube furnace, calcined parameters: heating rate 5 ° C · min -1 The calcination at a temperature of 600 ° C and the holding time is 5 h, the calcination atmosphere is Ar, and naturally cooling after calcination. After the above reaction, the product was washed with a 1 MHCl solution for 24 h to give a hollow black aluminum titanium oxide, remembered as a sample 1. # . Determination of the measurement element analysis, the molar ratio of the Al (Al + Ti) = 0.46 in the sample of the Ti element.

Embodiment 2

[0077] Example 2 Hollow Black Aluminum Titanium Oxide Solar Absorption Material Sample 2 # Preparation

[0078] Tell 5G Tio 2 Powder, 3 g of aluminum powder, grinding the two for 30 min, then poured into the nickel crucible, placing the nickel crucible in the tube furnace, calcined parameters: temperature rising 5 ° C · min -1 The calcination at a temperature of 600 ° C and the holding time is 5 h, the calcination atmosphere is Ar, and naturally cooling after calcination. After the above reaction, the product was washed with 1 M HCl solution for 24 h, gave a hollow black aluminum titanium oxide, remembered as a sample 2 # .

[0079] Table 1

[0080]

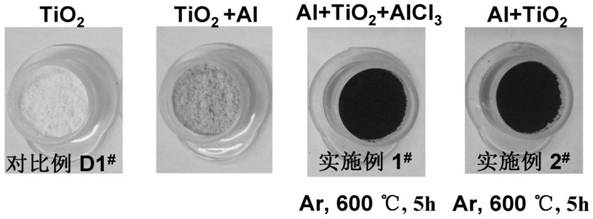

[0081] Al + TiO in the sample cover 2 Powder, contrast D1 # (Tio 2 Powder), sample 1 # ~ 2 # Such as figure 1 Indicated. From figure 1 It can be seen that the sample 1 after calcination and pickling # ~ 2 # Black is presented.

Embodiment 3

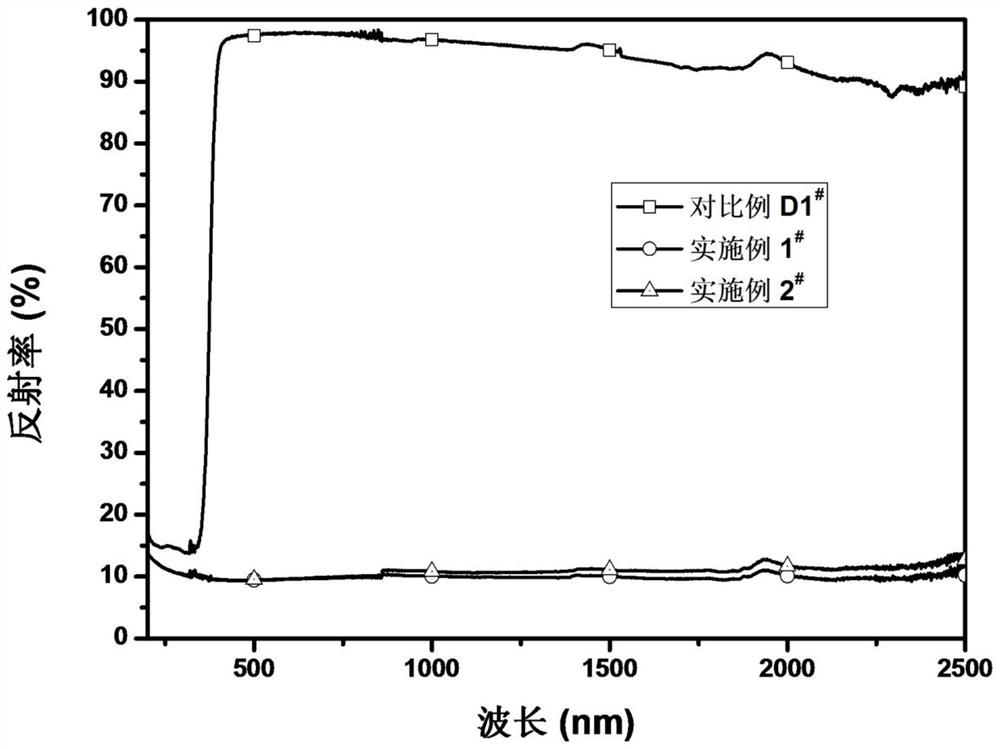

[0082] Example 3 Parallel sample D1 # (Tio 2 Powder), sample 1 # ~ 2 # Light absorption characterization

[0083] Contracted sample D1 # , Sample 1 # ~ 2 # Perform ultraviolet - visible - near-infrared diffuse reflection test, such as figure 2 Indicated. The results show that the hollow black aluminum titanium oxide solar absorbing material provided in this application, and the optical absorption can exceed 90% in the wavelength range of 200 nm to 2500 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com