A biomimetic hydroxyapatite powder/gelatin/sodium alginate composite 3D printing scaffold and preparation method thereof

A technology of hydroxyapatite and sodium alginate, applied in prosthesis, tissue regeneration, additive processing, etc., can solve problems such as unfavorable stem cell growth, enhance osteogenic activity and osteoinductivity, and promote bone tissue regeneration and repair , rheology and stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation of hydroxyapatite powder with hierarchical structure:

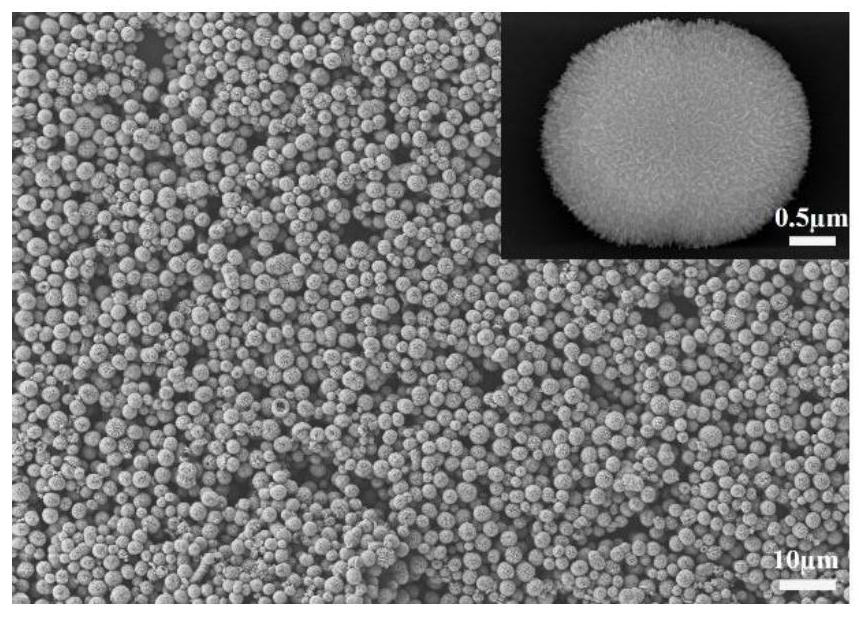

[0067] Configured with 24mM (NH4) 2 PO 4 solution, adjust the pH to 6.0 to obtain solution a. 40mmol of Ca(NO 3 ) 2 4H 2 O was added to solution a, fully dissolved, and stirred evenly to obtain solution b. Then add 6mmol of sodium citrate into solution b and stir vigorously to obtain a mixed solution. The mixture was transferred to a polytetrafluoroethylene-lined autoclave, and reacted at 180° C. for 3 h. After centrifugal washing and freeze-drying, the hydroxyapatite powder (ie HA particles) with hierarchical structure was obtained. Under the observation of scanning electron microscope, its appearance was as follows: figure 1 shown. The HA particles have a surface micro-nano hierarchical structure and a hollow structure, and the specific surface area is as high as 106.7m 2 / g.

Embodiment 2

[0069] The preparation of hydroxyapatite powder / gelatin / sodium alginate composite 3D printing scaffold includes the following steps:

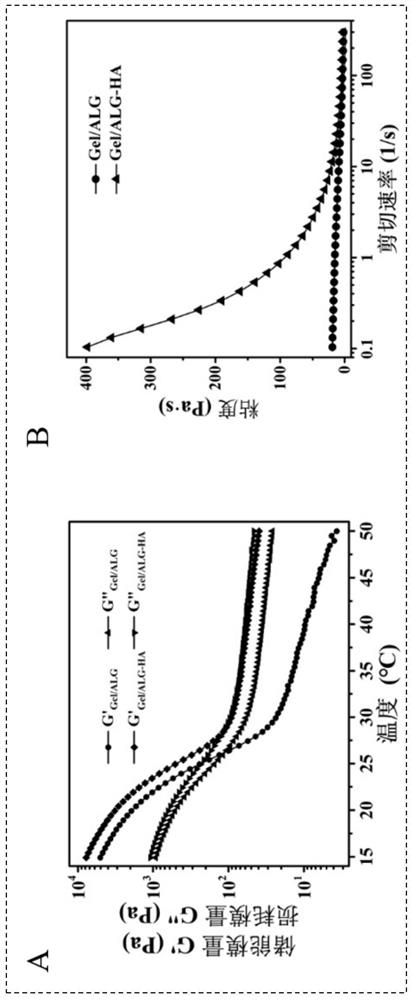

[0070] (1) Preparation of hydroxyapatite powder / gelatin / sodium alginate composite slurry: take 5g of gelatin particles, add to 50mL of deionized water, fully magnetically stir, stir evenly, and obtain a concentration of 0.1g / mL gelatin solution; then add 5 g of the HA particles obtained in Example 1, and stir until the HA particles are evenly dispersed in the gelatin solution; add 2.2 g of sodium alginate to the above solution, stir well, and ultrasonically remove air bubbles to obtain printing paste;

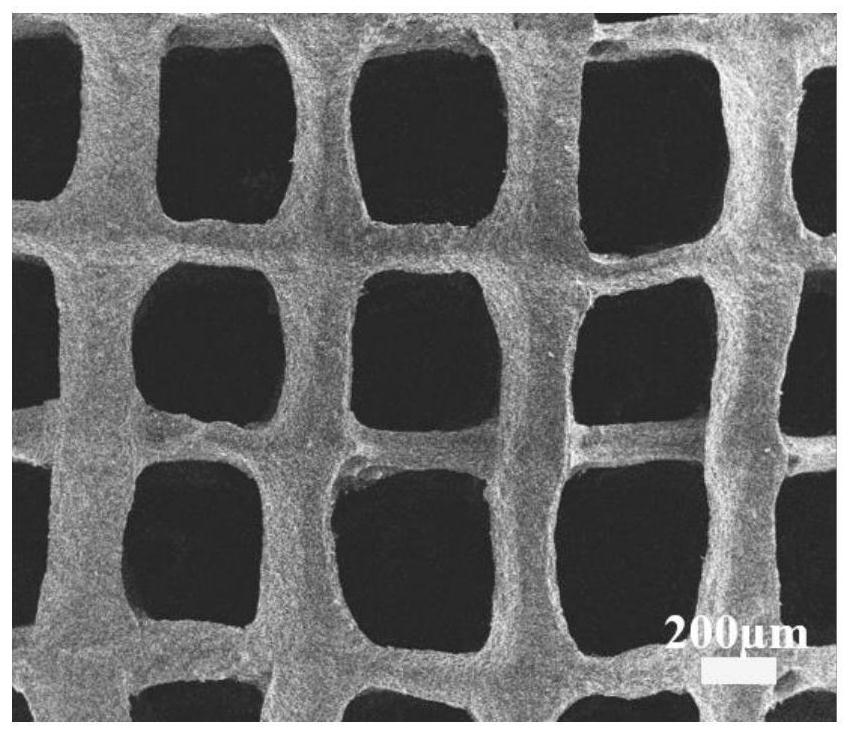

[0071] (2) Preparation of biomimetic 3D printing scaffold: put the composite slurry of hydroxyapatite particles / gelatin / sodium alginate (that is, the printing slurry) into the barrel, the diameter of the needle is 0.4mm, and the external dimensions of the scaffold material are designed It is a circle with a diameter of 10mm and a height of 2mm....

Embodiment 3

[0073] The preparation of hydroxyapatite powder / gelatin / sodium alginate composite 3D printing scaffold includes the following steps:

[0074] (1) Preparation of hydroxyapatite powder / gelatin / sodium alginate composite slurry: take 5g of gelatin particles, add them to 50mL of deionized water, and fully magnetically stir to obtain a gelatin solution with a concentration of 0.1g / mL Then add 7.5g of the HA particles obtained in Example 1, and stir until the HA particles are evenly dispersed in the gelatin solution; add 1.8g of sodium alginate to the above solution, stir well, and ultrasonically remove air bubbles, and the printing paste is prepared material;

[0075] (2) Preparation of biomimetic 3D printing scaffold: put the composite slurry of hydroxyapatite particles / gelatin / sodium alginate (that is, the printing slurry) into the barrel, the diameter of the needle is 0.4mm, and the external dimensions of the scaffold material are designed It is a circle with a diameter of 10mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com