A kind of preparation method of three-dimensional nanostructure nickel cobalt sulfide material

A nickel-cobalt sulfide, three-dimensional nanotechnology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of energy storage devices limited by energy density and power balance, and achieve excellent electrochemical performance, Large specific surface area, simple and practical method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

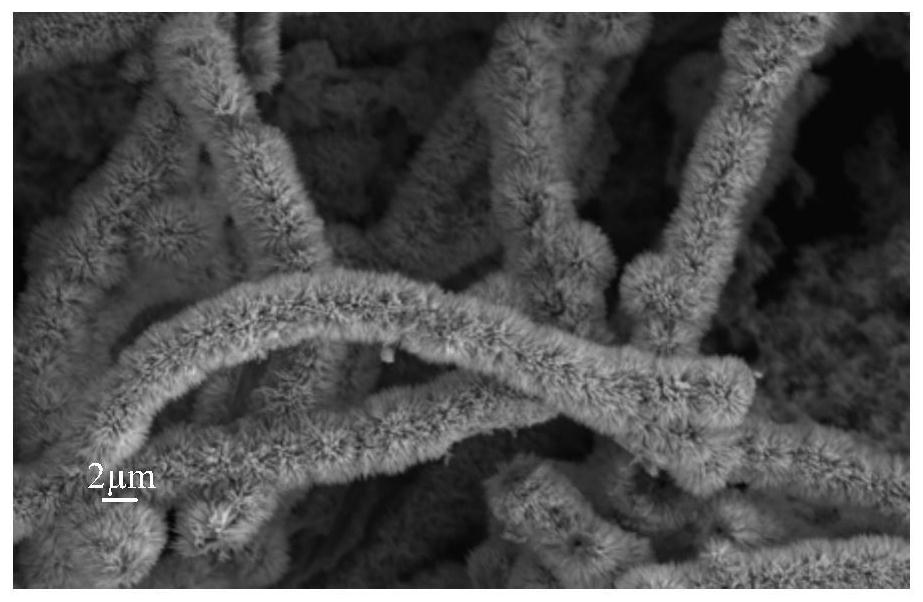

[0062] 1) Preparation of Ni-Co-S electrode with tubular fiber structure

[0063] The samples of tubular fiber structure with different vulcanization times, acetylene black and polyvinylidene fluoride (PVDF) were weighed according to the mass ratio of 8:1:1, and the weighed powder was put into an agate mortar for grinding until three Mix the powder completely, then transfer the powder to a 25mm×25mm weighing bottle, put a magnetic stirrer, and slowly add N-methylpyrrolidone (NMP) dropwise to allow the solution to completely soak the powder, then place the weighing bottle on Stir for 4 hours on a magnetic stirrer to obtain a viscous liquid. Afterwards, the viscous liquid was scraped and coated on the cleaned carbon cloth with a blade, and then dried in a vacuum drying oven to obtain a flexible electrode sheet.

[0064] The size of the above-mentioned carbon cloth is 2cm×1.5cm, and the cleaning can be performed by adding acetone, deionized water, and absolute ethanol in sequence...

Embodiment 2

[0069] 1) Preparation of Ni-Co-S electrodes with nano-petal-like structure

[0070] The samples of nano petal-like structure, acetylene black and polyvinylidene fluoride (PVDF) with different vulcanization time were weighed according to the mass ratio of 8:1:1, and the weighed powder was put into an agate mortar for grinding until three Mix the seed powder completely, then transfer the powder to a weighing bottle of 25mm×25mm, put in a magnetic stirrer, and slowly add N-methylpyrrolidone (NMP) dropwise, so that the solution completely infiltrates the powder, and then place the weighing bottle Stir for 4 h on a magnetic stirrer to obtain a viscous liquid. Afterwards, the viscous liquid was scraped and coated on the cleaned carbon cloth with a blade, and then dried in a vacuum drying oven to obtain a flexible electrode sheet.

[0071] The size of the above-mentioned carbon cloth is 2cm×1.5cm, and the cleaning can be performed by adding acetone, deionized water, and absolute eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com