Aluminum alloy surface high-corrosion-resistant wear-resistant iron-based amorphous coating and preparation method thereof

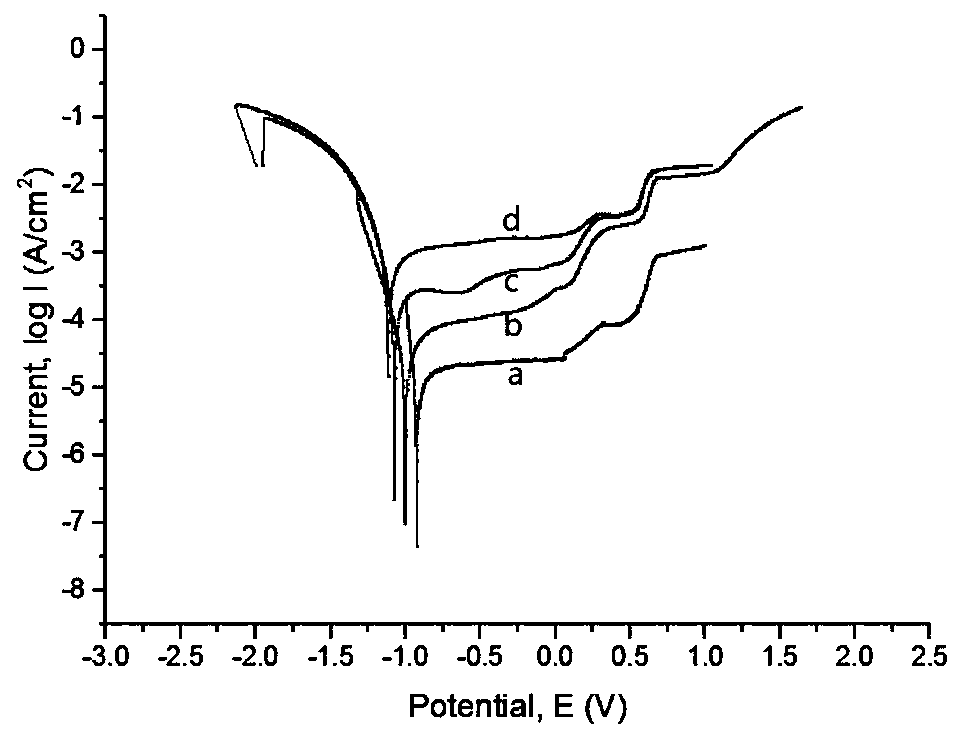

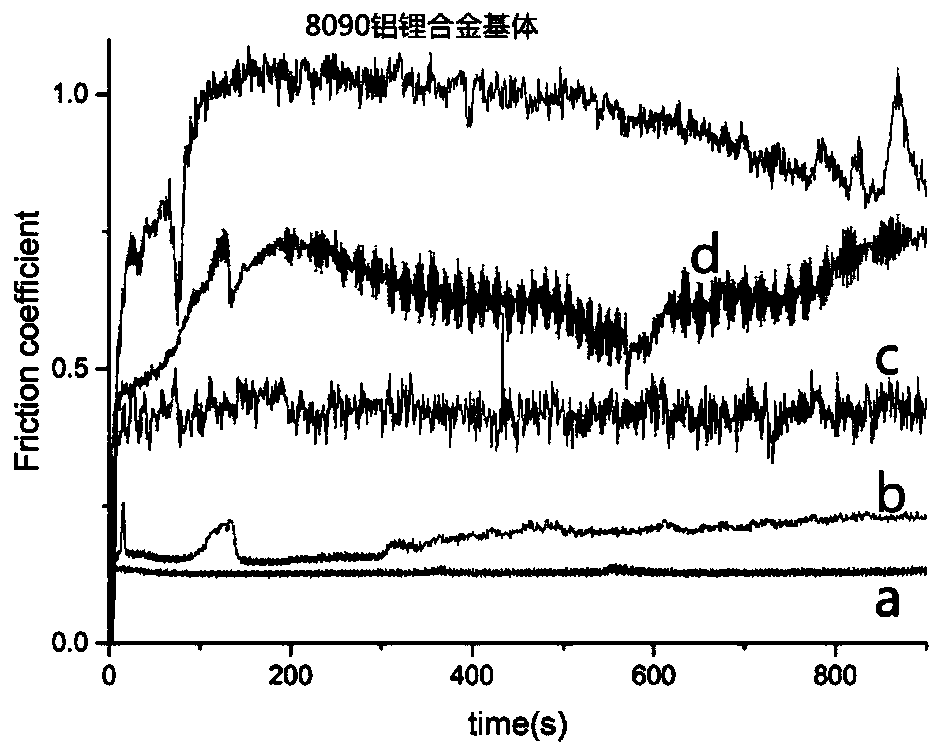

An aluminum alloy surface, iron-based amorphous technology, applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of low surface hardness, easy corrosion and wear, corrosion and wear of aluminum alloy, etc., to achieve enhanced Effects of durability, enhanced bonding strength, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Select 8090 Al-Li alloy as the matrix material, and pretreat the Al-Li alloy matrix. First, use 800# sandpaper to polish the substrate, and then place it in ethanol for ultrasonic cleaning. After ultrasonic cleaning for 4 minutes, place it at room temperature to dry naturally;

[0034] (2) 30 minutes before spraying, perform sandblasting on the pretreated aluminum alloy substrate. The abrasive used for sandblasting is 20# white corundum sand, the pressure of sandblasting is 0.6MPa, the speed is 0.6cm / s, and the time is 6min

[0035] (3) Dry the iron-based amorphous powder in the particle size range of 30-50 μm and the Ni60 powder in the particle size range of 38-75 μm under vacuum conditions at 100° C. for 1 hour;

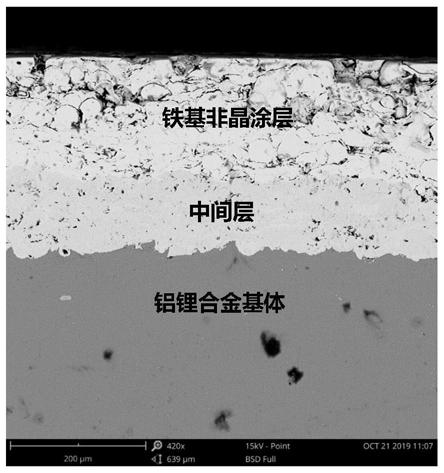

[0036] (4) the aluminum alloy substrate that step (2) is obtained is fixed; With described step (4) gained dry Ni60 powder and iron-based amorphous alloy powder as the material to be sprayed, the material to be sprayed is loaded into the supersonic flam...

Embodiment 2

[0040] (1) Select 8090 aluminum-lithium alloy as the base material, and pretreat the aluminum alloy base. First, use 800# sandpaper to polish the substrate, and then place it in ethanol for ultrasonic cleaning. After ultrasonic cleaning for 4 minutes, place it at room temperature to dry naturally;

[0041] (2) 30 minutes before spraying, perform sandblasting on the pretreated aluminum alloy substrate. The abrasive used for sandblasting is 20# white corundum sand, the pressure of sandblasting is 0.6MPa, the speed is 0.6cm / s, and the time is 6min

[0042] (3) Dry the iron-based amorphous powder in the particle size range of 30-50 μm and the Ni60 powder in the particle size range of 38-75 μm under vacuum conditions at 100° C. for 1 hour;

[0043] (4) the aluminum alloy substrate that step (2) is obtained is fixed; With described step (4) gained dry Ni60 powder and iron-based amorphous alloy powder as the material to be sprayed, the material to be sprayed is loaded into the super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com