Preparation method for 2D/2D nitrogen-doped lanthanum titanate/sulfur-indium-zinc heterojunction photocatalyst

A photocatalyst and heterojunction technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as autoxidation reaction, small specific surface area, photocorrosion, etc., and achieve improved photocatalytic performance, The reaction conditions are simple and the effect of solving the problem of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

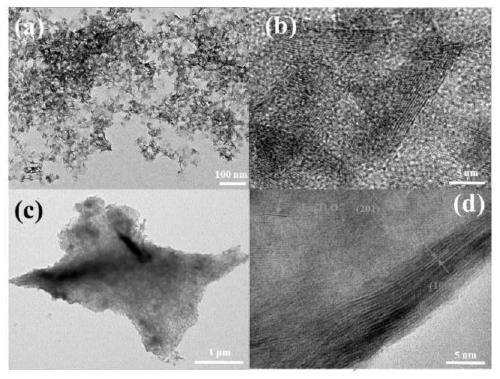

[0031] (1) Two-dimensional La 2 Ti 2 o 7 Preparation of nanosheets: Weigh 1g Ti(SO 4 ) 2 9H 2 O with 1.8g La(NO 3 )·6H 2 Add O into 60mL of deionized water, stir for 10min, and record it as solution A; dissolve 1g of NaOH in 10mL of deionized water, disperse it ultrasonically, and record it as solution B; under magnetic stirring, add solution B into solution A, and stir 4h, marked as liquid C; transfer liquid C to a reaction kettle, react at 220°C for 20h, cool to room temperature, centrifuge and wash 3 times, and dry at 60°C to obtain La 2 Ti 2 o 7 Nanosheets.

[0032] (2) Two-dimensional nitrogen-doped La 2 Ti 2 o 7 Preparation of nanosheets: 0.3g La 2 Ti 2 o 7 Add the nanosheets to 30mL of triethanolamine, stir vigorously at room temperature for 8-12h, then transfer the mixture to a reaction kettle, react at 220°C for 40h, cool to room temperature, centrifuge and wash 3 times, and dry at 60°C. Obtain N-doped La 2 Ti 2 o 7 Nanosheets.

[0033] (3) Two-dim...

Embodiment 2

[0036] (1) Two-dimensional La 2 Ti 2 o 7 Preparation of nanosheets: Weigh 1.5g Ti(SO 4 ) 2 9H 2 O with 2.7g La(NO 3 )·6H 2 Add O into 60mL of deionized water, stir for 10min, and record it as liquid A; dissolve 1.5g of NaOH in 10mL of deionized water, disperse it ultrasonically, and record it as liquid B; under magnetic stirring, add liquid B into liquid A, Stir for 4 hours and mark it as solution C; transfer solution C to a reaction kettle, react at 230°C for 26 hours, cool to room temperature, centrifuge and wash 3 times, and dry at 60°C to obtain La 2 Ti 2 o 7 Nanosheets.

[0037] (2) Two-dimensional nitrogen-doped La 2 Ti 2 o 7 Preparation of nanosheets: 0.5g La 2 Ti 2 o 7 Add nanosheets to 30mL of triethanolamine, stir vigorously at room temperature for 8-12h, then transfer the mixture to a reaction kettle, react at 230°C for 50h, cool to room temperature, centrifuge and wash 3 times, and dry at 60°C. Obtain N-doped La 2 Ti 2 o 7 Nanosheets.

[0038] (...

Embodiment 3

[0041] (1) Two-dimensional La 2 Ti 2 o 7 Preparation of nanosheets: Weigh 2g Ti(SO 4 ) 2 9H 2 O with 3.6g La(NO 3 )·6H 2 Add O into 60mL of deionized water, stir for 10min, and record it as liquid A; dissolve 2g of NaOH in 10mL of deionized water, disperse it ultrasonically, and record it as liquid B; under magnetic stirring, add liquid B into liquid A, and stir 4h, marked as liquid C; transfer liquid C to the reaction kettle, react at 240°C for 24h, cool to room temperature, centrifuge and wash 3 times, and dry at 60°C to obtain La 2 Ti 2 o 7 Nanosheets.

[0042] (2) Two-dimensional nitrogen-doped La 2 Ti 2 o 7 Preparation of nanosheets: 1g La 2 Ti 2 o 7 Add the nanosheets into 50mL of triethanolamine, stir vigorously at room temperature for 8-12h, then transfer the mixture to a reaction kettle, react at 240°C for 48h, cool to room temperature, centrifuge and wash 3 times, and dry at 60°C. Obtain N-doped La 2 Ti 2 o 7 Nanosheets.

[0043] (3) Two-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com