Vertical grinding machine production ultra-fine filling material and surface treatment composite technique

A technology of ultra-fine filler and composite process, applied in the direction of dyeing physical treatment, etc., can solve the problems of increasing the cost of electric energy, increasing manpower, material resources, and backward production of ultra-fine filler, etc., and achieve the effect of fracture resistance strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

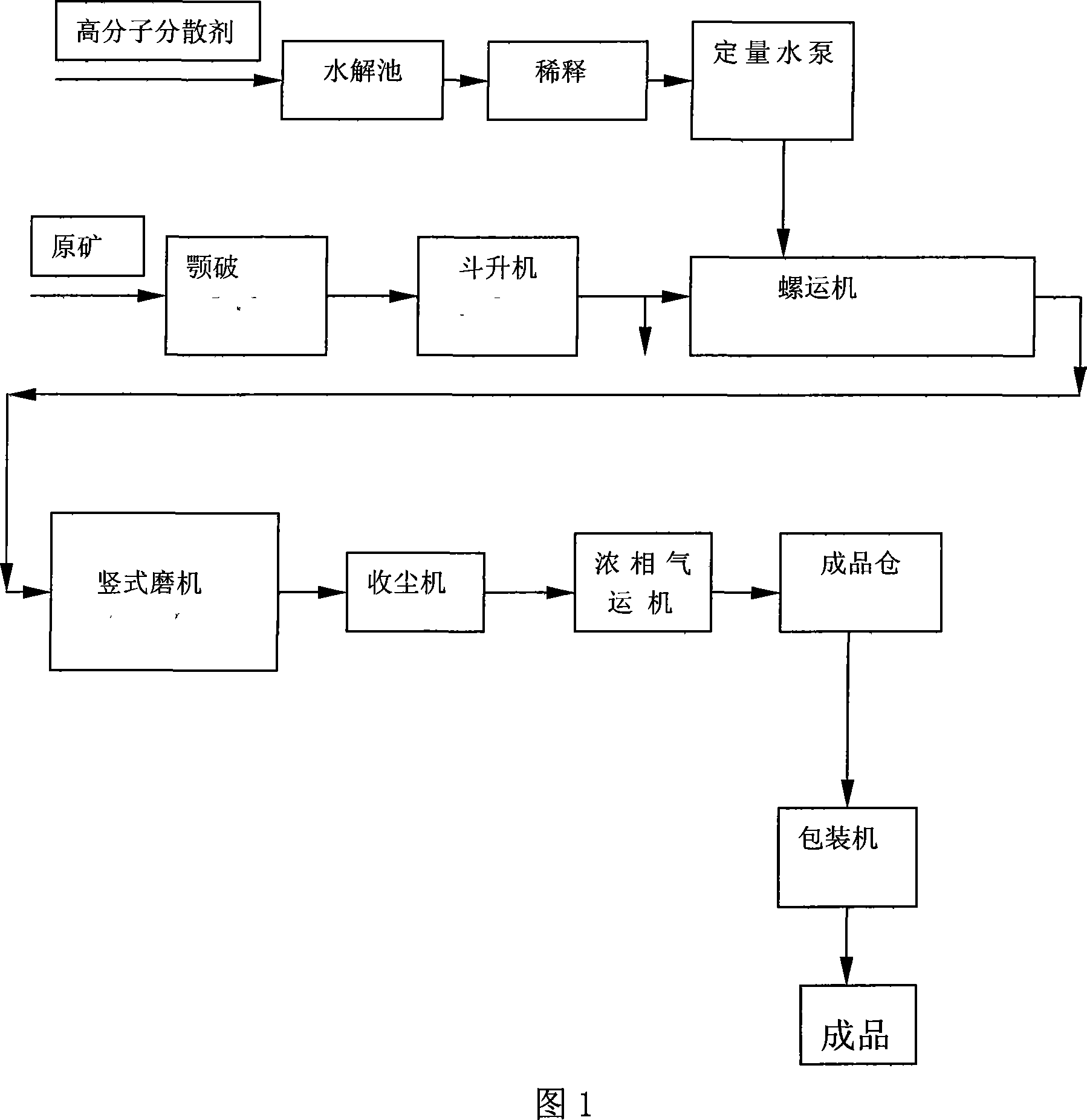

[0011] As shown in Figure 1, a composite process for producing superfine fillers and surface treatment by a vertical mill in the present invention includes the following steps: firstly prepare materials, use a crusher to compress the raw ore into primary crushed powder, and pass through a bucket elevator and a screw The conveyor transports it to the vertical mill to grind it into ultra-fine filler powder, and then uses the dense phase air conveyor to transport the ultra-fine filler powder to the finished product warehouse for packaging as finished products. In addition, it also includes Add the hydrolyzed surfactant mixture with a content of 8% to 16% into the screw conveyor for full mixing. Among them, the surfactant mixture is formed by hydrolyzing the polymer dispersant through the hydrolysis tank first, and then adding water to dilute it. The surfactant mixture is transported to the screw conveyor through a quantitative water pump, and enters the vertical mill for grinding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com