A Method for Generating Orthogonal Polarization Synchronous Pulsed Laser Based on Double 45°-mgo:ln Cavity Dumping

A synchronous pulse and orthogonal polarization technology, applied in the laser field, can solve the problems of low stability and economy, poor beam quality, low output power, etc., and achieve high-power polarized pulse laser output with improved light-to-light conversion efficiency , The effect of reducing the crystal voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

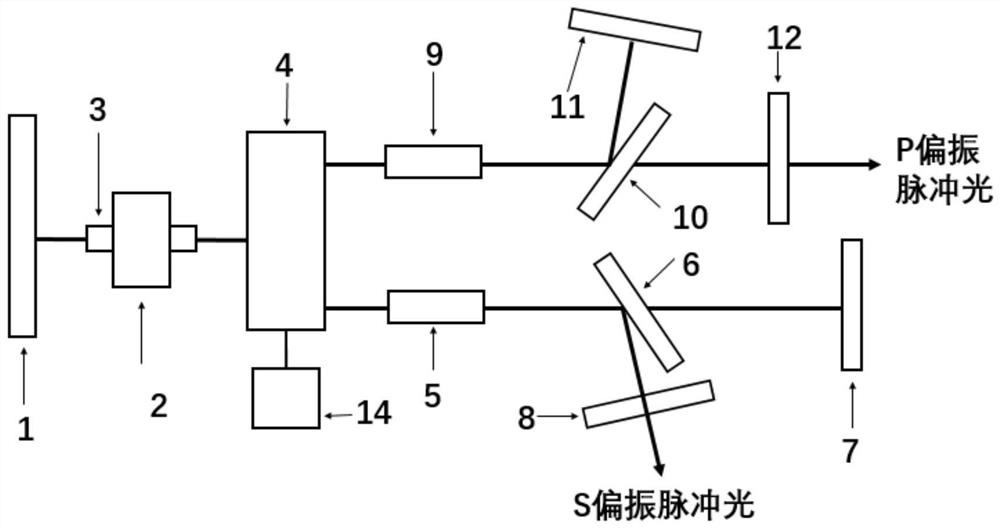

[0044] Such as figure 1 As shown in the schematic diagram, the resonant cavity mirror adopts a plano-concave mirror coated with a 1064nm total reflection film (HR, R>99.7%)

[0045] , radius of curvature R=1m; the pump source 808nm laser diode array side pump source; the gain medium is Nd:YAG crystal rod, size Φ4mmX67mm, Nd 3+ The doping concentration is 1.0mol%, and the two ends are coated with a 1064nm high-transparency film (AR, R2 ;; The s-light-total reflection mirror and the p-light-total reflection mirror are all just coated with a flat mirror with a 1064nm high-reflection film (HR, R>99.7%); the s-light-output mirror and p-light-output mirror A flat mirror is adopted, and the transmittance to 1064nm is 20%at; the size of the block MgO:LN crystal is 7mm×7mm×20mm, and the transparent end is coated with a 1064nm high-transparency film, and the doping concentration of MgO is 5.5mol%. Realize 1064nm narrow pulse width and high peak power synchronously pulsed 1064nm laser w...

Embodiment 2

[0047] Same as Example 1, the main difference is that the 808nm laser diode array side pumping source in Example 1 is replaced by 808nm continuous end pumping laser and then enters the resonant cavity through the pump light shaping system to realize 1064nm laser oscillation output.

Embodiment 3

[0049] Replace the two double-cavity emptying optical paths behind the 45°-MgO:LN crystal with two acousto-optic Q-switched optical paths, that is, two acousto-optic modulated orthogonally polarized synchronous pulse lasers can be realized. The advantage is that the cavity structure is simpler compact.

[0050] In summary, the present invention discloses a dual 45°-MgO:LN cavity-dumped orthogonal polarization synchronous pulse laser generation method. The laser device sequentially includes a front cavity mirror, a pump source, a laser gain medium, a double 45° doped magnesium oxide lithium niobate crystal (double 45°-MgO:LN), an s-light-polarization cavity emptying device, and a p Light-polarizing cavity emptying device. Applying a transverse λ / 2 voltage to the double 45°-MgO:LN crystal is used to control synchronous orthogonally polarized pulse output. The s light-polarization cavity emptying device and the p light-polarization cavity emptying device respectively control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com