Composite chromium-free corrosion inhibition passivator as well as preparation and application thereof

A passivating agent and composite technology, applied in the coating process of metal materials, etc., can solve the problems of short protection period, poor corrosion resistance, weak adhesion of passivation layer, etc., and achieve comprehensive quality improvement, prolong protection period, effective Facilitate the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

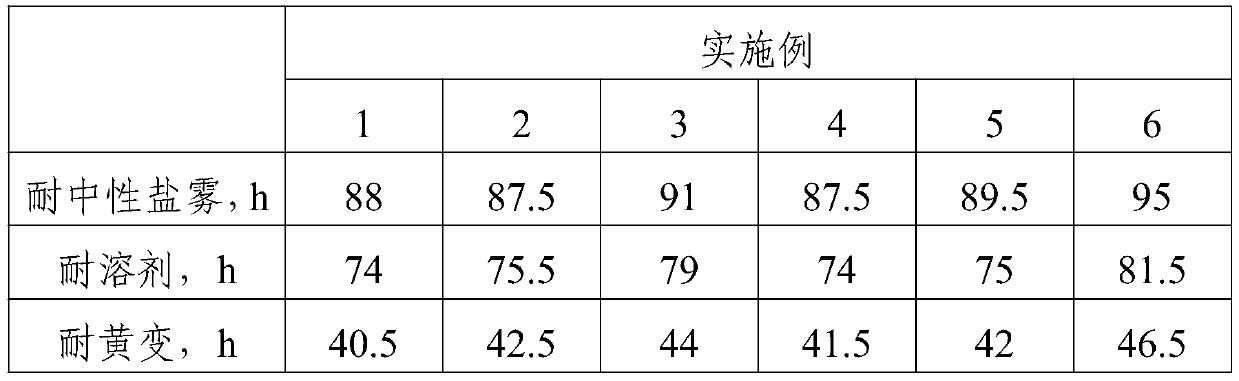

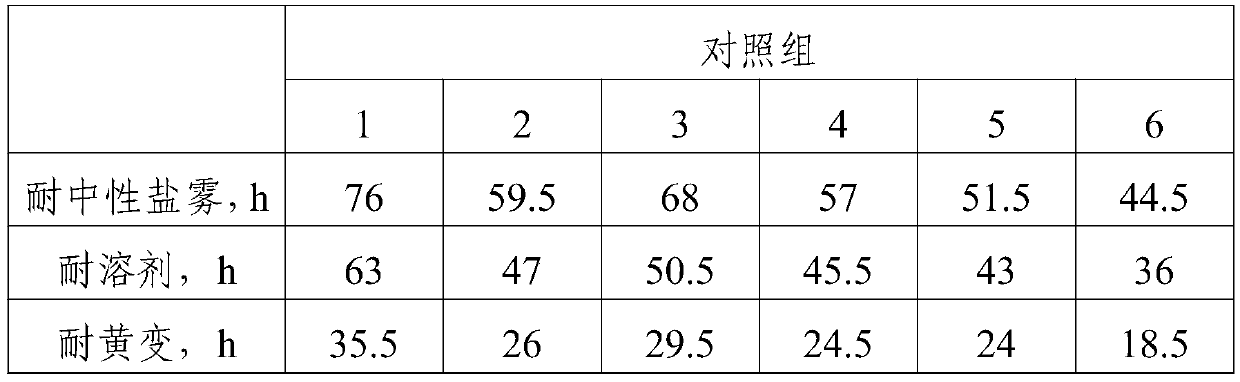

Examples

Embodiment 1

[0029] A composite chromium-free corrosion inhibitor and passivation agent, consisting of agent A and agent B with a mass ratio of 1:2.5, wherein agent A includes humic acid, barium metaborate, magnesium nitride, hydrogenated polydimethylsiloxane, Styrene-acrylic emulsion; agent B includes phosphate, nano-scale ore powder, plant slurry, bis(dicarbonyl cyclopentadienyl iron), silane coupling agent, water-based silicone resin, and deionized water.

[0030]The mass percentage content of each component in agent A is: humic acid 20%, barium metaborate 8%, magnesium nitride 8%, hydrogenated polydimethylsiloxane 6%, styrene-acrylic emulsion balance; The preparation steps are as follows: grind humic acid at 25-30°C under a nitrogen / ammonia atmosphere, then add barium metaborate and magnesium nitride into it alternately in 2 equal parts, and keep grinding for 3 hours to obtain a mixture; The styrene-acrylic emulsion is preheated and stirred at 35±5°C for 20 minutes, then hydrogenated p...

Embodiment 2

[0036] A composite chromium-free corrosion inhibitor and passivation agent, consisting of agent A and agent B with a mass ratio of 1:2.5, wherein agent A includes humic acid, barium metaborate, magnesium nitride, hydrogenated polydimethylsiloxane, Styrene-acrylic emulsion; agent B includes phosphate, nano-scale ore powder, plant slurry, bis(dicarbonyl cyclopentadienyl iron), silane coupling agent, water-based silicone resin, and deionized water.

[0037] The mass percentage content of each component in agent A is: humic acid 30%, barium metaborate 10%, magnesium nitride 10%, hydrogenated polydimethylsiloxane 8%, styrene-acrylic emulsion balance; The preparation steps are as follows: grind humic acid at 25-30°C under a nitrogen / ammonia atmosphere, then add barium metaborate and magnesium nitride into it alternately in 2 equal parts, and keep grinding for 4 hours to obtain a mixture; The styrene-acrylic emulsion is preheated and stirred at 35±5°C for 30 minutes, then hydrogenate...

Embodiment 3

[0043] A composite chromium-free corrosion inhibitor and passivation agent, consisting of agent A and agent B with a mass ratio of 1:2.5, wherein agent A includes humic acid, barium metaborate, magnesium nitride, hydrogenated polydimethylsiloxane, Styrene-acrylic emulsion; agent B includes phosphate, nano-scale ore powder, plant slurry, bis(dicarbonyl cyclopentadienyl iron), silane coupling agent, water-based silicone resin, and deionized water.

[0044] The mass percentage content of each component in agent A is: humic acid 15%, barium metaborate 5%, magnesium nitride 10%, hydrogenated polydimethylsiloxane 6%, styrene-acrylic emulsion balance; The preparation steps are as follows: grind humic acid at 25-30°C under a nitrogen / ammonia atmosphere, then add barium metaborate and magnesium nitride into it alternately in 3 equal parts, and keep grinding for 4 hours to obtain a mixture; The styrene-acrylic emulsion is preheated and stirred at 35±5°C for 20 minutes, then hydrogenated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com