Alkaline-water-resistant lubricating grease and preparation method thereof

A technology of lubricating grease and alkaline water, applied in the field of lubrication, can solve the problems of bearing rust damage, poor protection performance, bearing rust, etc., and achieve the effect of neat molecular composition of polyurea and good shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

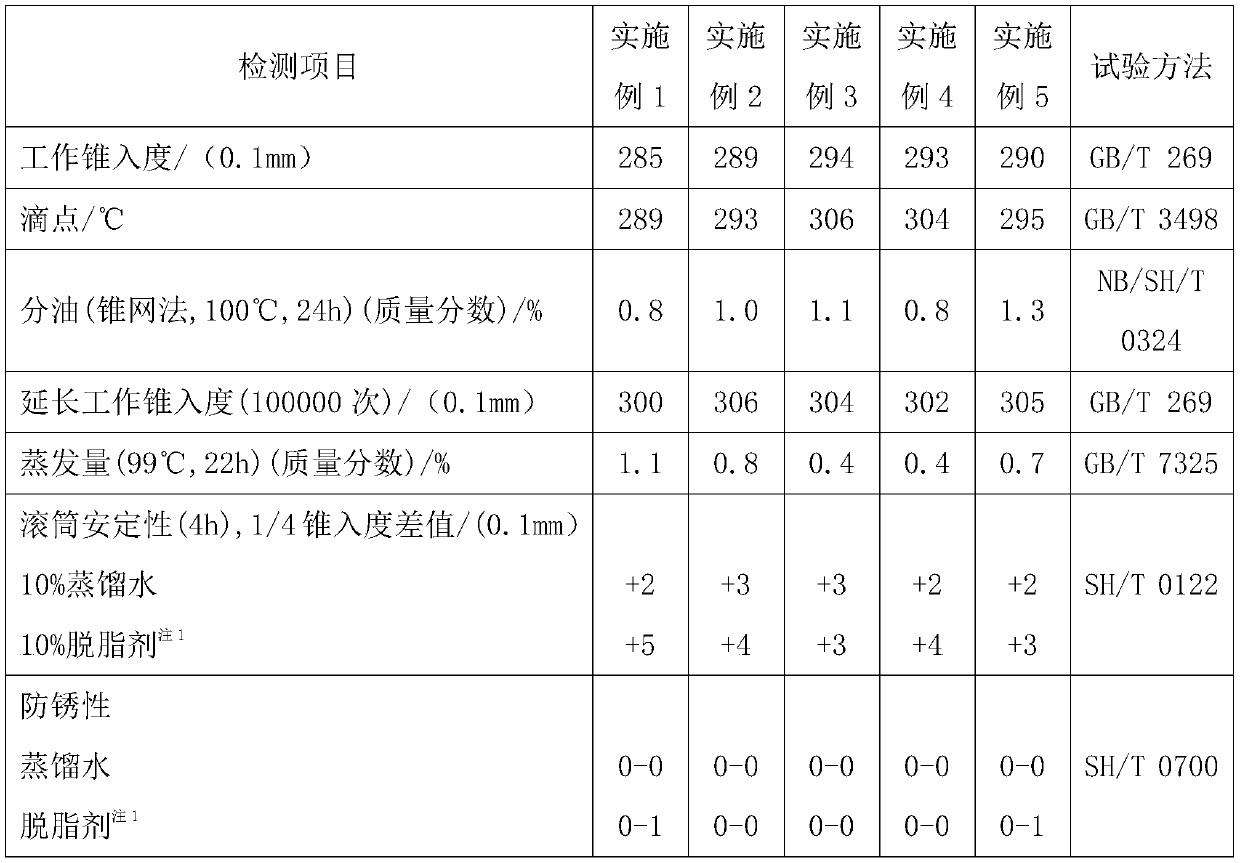

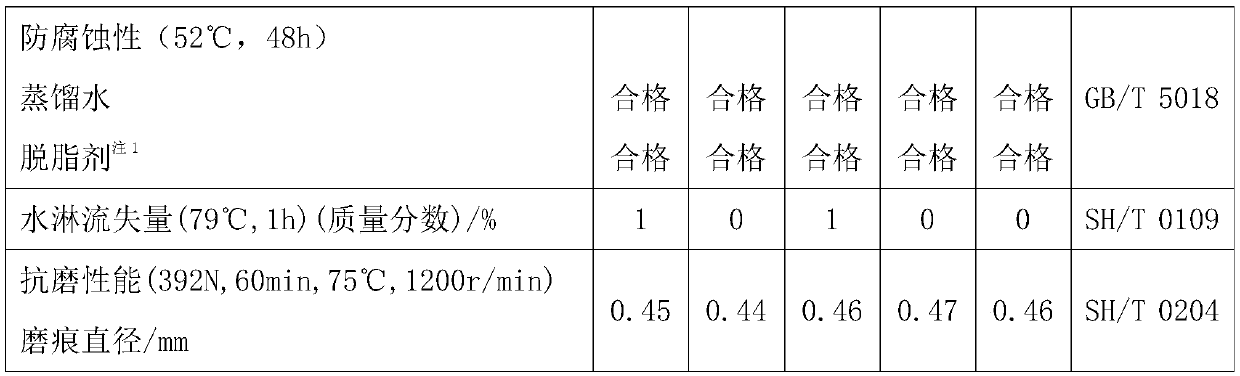

Examples

Embodiment 1

[0064] An alkaline water-resistant grease consisting of the following components: naphthenic oil: 257.6kg; paraffinic base oil: 601.1kg; 4.4`-diphenylmethane diisocyanate: 61.3kg; aniline: 12.8kg; cyclohexylamine : 36.2kg; Nonyl diphenylamine: 3kg; Maleic anhydride grafted polyethylene wax: 2kg; Sodium petroleum sulfonate: 5kg; Sorbitan monooleate: 5kg; Calcium bicarbonate: 8kg; Polyaluminum chloride: 3kg; zinc carbamate: 5kg.

[0065] The preparation method of anti-alkali water lubricating grease is as follows:

[0066]Mix naphthenic oil and paraffin base oil with maleic anhydride grafted polyethylene wax, heat up to 40-50°C; half of the mixed oil is used to dissolve 4.4`-diphenylmethane diisocyanate, and the other half is used To dissolve aniline; after all the dissolution, 3 / 5 of the dissolved oil of 4.4`-diphenylmethane diisocyanate is mixed with the dissolved oil of aniline to carry out a one-step polymerization reaction for 1.5~2.0h; after the reaction, add cyclohexylam...

Embodiment 2

[0068] An alkaline water-resistant lubricating grease, consisting of the following components: naphthenic oil: 254.1kg; second-class hydrogenated oil: 592.8kg; 4.4`-diphenylmethane diisocyanate: 71.9kg; aniline: 15.9kg; Hexylamine: 42.3kg; phenyl α-naphthylamine: 4kg; maleic anhydride grafted polyethylene wax: 2.5kg; petroleum calcium sulfonate: 5kg; magnesium bicarbonate: 4kg; polyaluminum chloride: 3.5kg; 4kg.

[0069] The preparation method of anti-alkali water lubricating grease is as follows:

[0070] Mix naphthenic oil and type II hydrogenated oil with maleic anhydride grafted polyethylene wax, heat up to 40-50°C, half of the mixed oil is used to dissolve 4.4`-diphenylmethane diisocyanate, and the other Half of it is used to dissolve aniline; after all of it is dissolved, 2 / 3 of the dissolved oil of 4.4`-diphenylmethane diisocyanate is mixed with the dissolved oil of aniline for one-step polymerization reaction for 1.5-2.0 hours; after the reaction, add cyclohexylamine ...

Embodiment 3

[0072] An alkaline water-resistant grease consisting of the following components: naphthenic oil: 289.1kg; paraffinic base oil: 289.2kg; polyalphaolefin: 247.9kg; 2.4-tolyl diisocyanate: 77.6kg; aniline: 16.9kg ; Cyclohexylamine: 46.3kg; Methylene bis-dibutyldithiocarbamate: 10kg; Maleic anhydride grafted polyethylene wax: 3kg; Petroleum calcium sulfonate: 10kg; Magnesium bicarbonate: 4kg; Aluminum chloride: 2.5kg; dimercaptothiadiazole dimer: 3.5kg.

[0073] The preparation method of anti-alkali water lubricating grease is as follows:

[0074] Mix naphthenic oil, paraffin base oil and polyalphaolefin with maleic anhydride grafted polyethylene wax, heat up to 40-50°C, half of the mixed oil is used to dissolve 2.4-tolyl diisocyanate, and the other half It is used to dissolve aniline; after it is completely dissolved, 3 / 5 of the dissolved oil of 2.4-tolyl diisocyanate is mixed with the dissolved oil of aniline for one-step polymerization reaction for 1.5-2.0 hours; after the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com