Porous dielectric material, preparation method thereof and capacitive pressure sensor

A technology of dielectric material and filling material, which is applied in the direction of fluid pressure measurement, instrument, and measurement force using capacitance change, can solve the problems of inability to further improve the sensitivity of capacitive pressure sensor and small dielectric constant, and achieve good flexibility. , High dielectric constant, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

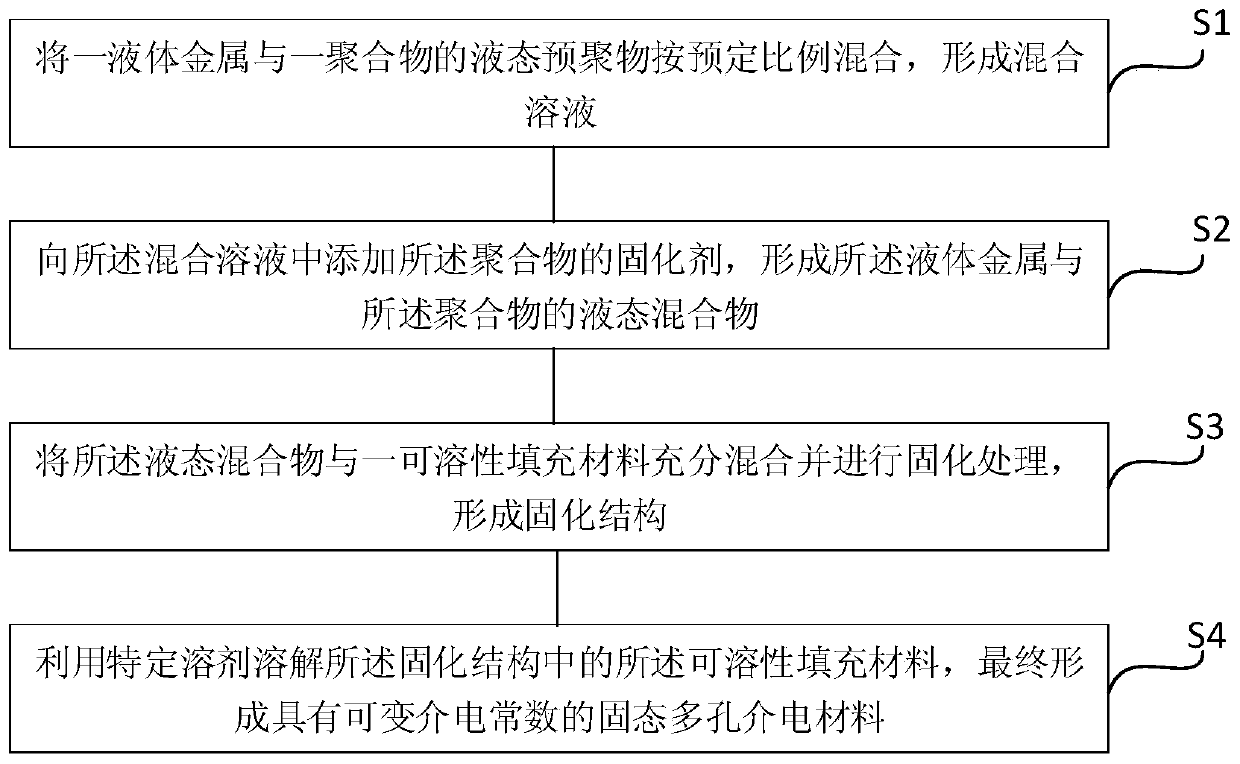

[0046] See figure 1 , figure 1 It is a flowchart of a method for preparing a porous dielectric material provided by an embodiment of the present invention.

[0047] The preparation method of the porous dielectric material comprises:

[0048] S1: Mixing a liquid metal and a liquid prepolymer of a polymer in a predetermined ratio to form a mixed solution;

[0049]In this embodiment, eutectic gallium indium or gallium indium tin alloy is selected as the liquid metal; platinum catalyzed silicone rubber, polydimethylsiloxane (PDMS) or silicone is selected as the polymer, and the polymer The material includes liquid prepolymer and matching curing agent. It should be noted that the silicone polymer material used in this example (such as platinum catalyzed silicone rubber, polydimethylsiloxane (PDMS) or silicone, etc.) contains two parts before mixing: prepolymer and The curing agent (cross-linking agent) is used together. After mixing the two parts, it will remain in a liquid sta...

Embodiment 2

[0086] On the basis of the first embodiment, this embodiment provides a porous dielectric material for a capacitive pressure sensor, and the porous dielectric material can be made by the preparation method described in the first embodiment.

[0087] Specifically, in this embodiment, eutectic gallium indium or gallium indium tin alloy is selected as the liquid metal; platinum catalyzed silicone rubber, polydimethylsiloxane (PDMS) or silicone is selected as the polymer, The polymer includes a liquid prepolymer and a corresponding curing agent.

[0088] Further, the liquid metal accounts for 10%-95% of the total mass of the porous dielectric material. as example one and Figure 5 As shown, as the volume fraction of liquid metal increases, the overall dielectric constant of the dielectric material increases gradually. However, too much liquid metal content will affect the flexibility and stretchability of the formed hybrid material, while too little liquid metal will lead to an ...

Embodiment 3

[0090] On the basis of the above embodiments, this embodiment provides a capacitive pressure sensor based on a porous dielectric material, the capacitive pressure sensor includes two electrode plates and a flexible dielectric between the two electrode plates layer, wherein the flexible dielectric layer is made of the above-mentioned porous dielectric material.

[0091] See Figure 8 , Figure 8 It is a performance curve diagram of a capacitive voltage sensor based on a porous dielectric material provided by an embodiment of the present invention, wherein the abscissa is the compressive stress, the ordinate is the capacitance, and different curves represent the liquid metal in the porous dielectric material. Volume ratio, liquid metal is 0% volume ratio, 10% volume ratio, 20% volume ratio, 30% volume ratio and 40% volume ratio. It should be noted that during the parameter test process, the liquid metal component is eutectic gallium indium, and the polymer component is platinu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com