CO & CO2 co-methanation catalyst and preparation method and application thereof

The technology of a methanation catalyst and auxiliary agent is applied in the field of CO&CO2 co-methanation catalyst and its preparation, which can solve the problems that the reaction conditions need to be further optimized, the catalyst preparation process is complicated, and the catalyst preparation cost is high, and the catalyst has good repeatability and good industrial performance. Application prospects, the effect of easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

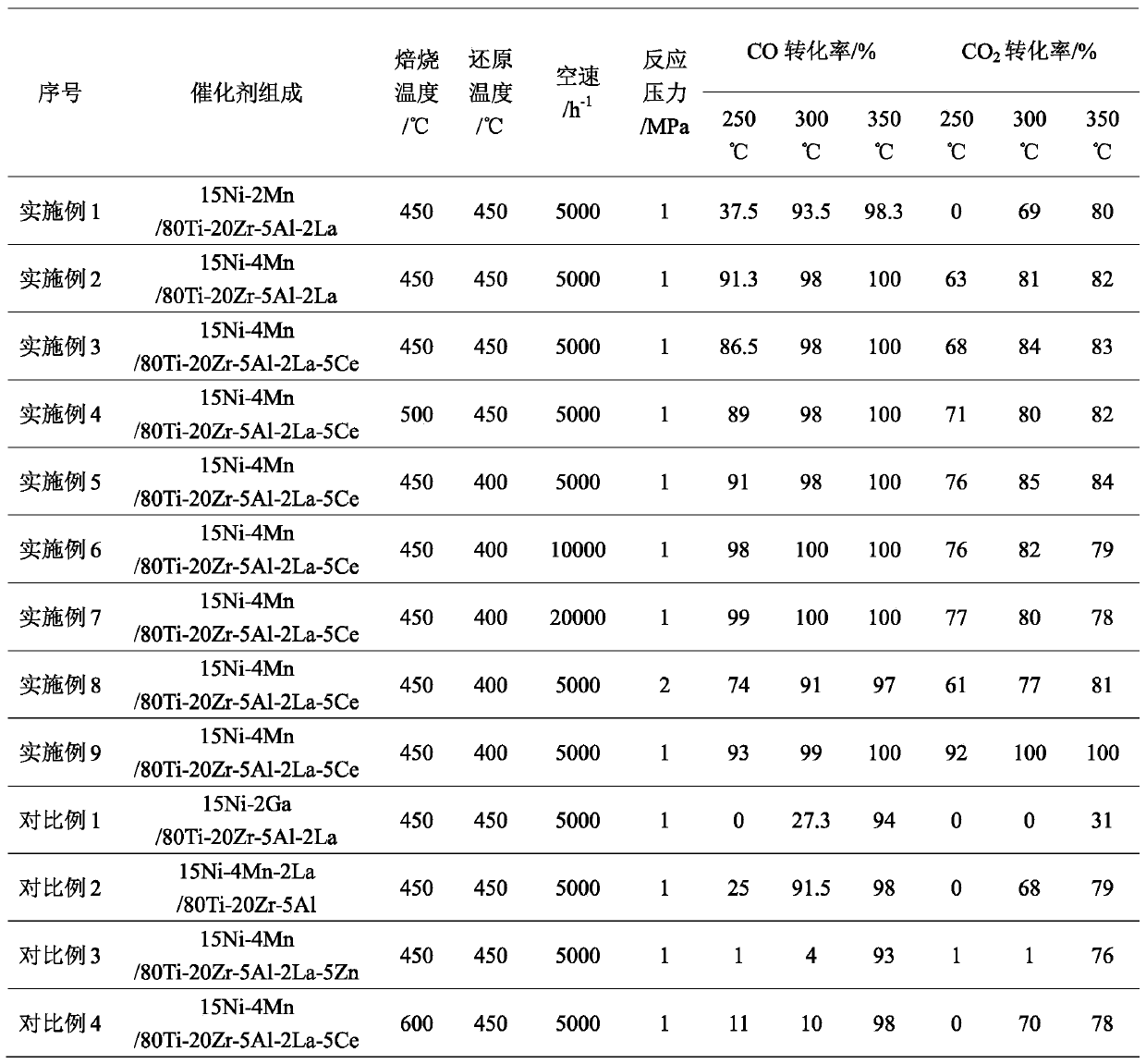

Examples

Embodiment 1

[0029] (1) Put 26.55g of lanthanum nitrate, 50g of pseudoboehmite and 10g of plant glue into the kneader, add 250mL of deionized water, add dilute nitric acid to adjust the pH to 3-4, fully knead to obtain aluminum sol, and then add 400g of TiO 2 powder and 278g Zr(OH) 4 The powder is mixed and kneaded into a plastic mass, and then extruded with an extruder to form a strip, left at room temperature for 6-20 hours, then dried at 80-120°C for 4-6h and roasted at 500°C for 4-8h to obtain the carrier;

[0030] (2) 5.9g of nickel nitrate, 0.823g of manganese nitrate and 5g of deionized water were prepared into a solution, and 10g of the above-mentioned carrier was impregnated in it, the number of immersions was 1-3 times, and the total time of immersion was 4-10h. Stand for 4-12h and dry at 110°C for 4-10h;

[0031] (3) Place the material obtained in step (2) in a muffle furnace, raise the temperature to 550°C at a heating rate of 2-5°C / min, and roast for 4-8h to obtain the CO&CO ...

Embodiment 2

[0034] (1) with embodiment 1;

[0035] (2) 5.9g of nickel nitrate, 1.646g of manganese nitrate and 5g of deionized water were prepared into a solution, and 10g of the above-mentioned carrier was impregnated in it. The number of immersions was 1-3 times, and the total time of immersion was 4-10h. Stand for 4-12h and dry at 110°C for 4-10h;

[0036](3) Place the material obtained in step (2) in a muffle furnace, raise the temperature to 550°C at a heating rate of 2-5°C / min, and roast for 4-8h to obtain the CO&CO 2 Co-methanation catalyst.

[0037] The CO&CO that this embodiment makes 2 Co-methanation catalyst for fixed bed CO&CO 2 Co-methanation reaction, the composition of the reaction gas contains CO, CO 2 and H 2 , H 2 The volume ratio of H and CO is 5:1, H 2 and CO 2 The volume ratio is 10:1, the space velocity of the reaction gas is 5000 / h, the reaction temperature is 450°C, the reaction time is 2h, and the reaction pressure is 1MPa.

Embodiment 3

[0039] (1) Put 26.55g of lanthanum nitrate, 63g of cerium nitrate, 50g of pseudoboehmite and 10g of plant glue into a kneader, add 250mL of deionized water, add dilute nitric acid to adjust the pH to 3-4, fully knead to obtain aluminum sol, and then Add 400g TiO 2 powder and 278gZr(OH) 4 The powder is mixed and kneaded into a plastic mass, and then extruded with an extruder to form a strip, left at room temperature for 6-20 hours, then dried at 80-120°C for 4-6h and roasted at 500°C for 4-8h to obtain the carrier;

[0040] (2) 5.9g of nickel nitrate, 1.646g of manganese nitrate and 5g of deionized water were prepared into a solution, and 10g of the above-mentioned carrier was impregnated in it. The number of immersions was 1-3 times, and the total time of immersion was 4-10h. Stand for 4-12h and dry at 110°C for 4-10h;

[0041] (3) Place the material obtained in step (2) in a muffle furnace, raise the temperature to 550°C at a heating rate of 2-5°C / min, and roast for 4-8h to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com