Preparation method of microcapsule fire extinguishing agent taking whey protein isolate/anionic polysaccharide as wall material

A technology of whey protein isolate and anionic polysaccharide, which is applied in the direction of fire prevention equipment, can solve the problems such as microencapsulation, and achieve the effects of suppressing or extinguishing fire, safe use and high fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

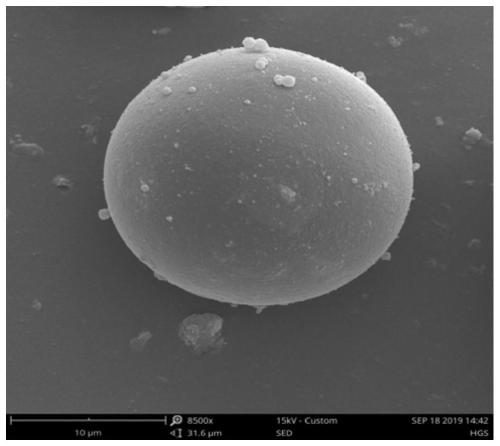

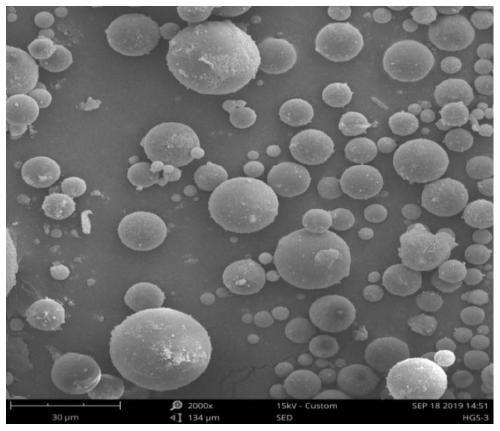

[0028] A whey protein isolate, anionic polysaccharide coated low-boiling point liquid fire extinguishing agent, and a method for preparing fire extinguishing agent microcapsules, comprising the following steps:

[0029] (1) Configuration of the wall material solution: respectively configure a whey protein isolate aqueous solution with a concentration of 2%, and an aqueous gum arabic solution with a concentration of 2%;

[0030] (2) Preparation of emulsion: Measure 50ml of 2% whey protein isolate solution in a three-necked flask, weigh 0.24g of Span80 and 2ml of tetrafluorodibromoethane, mix and stir, then slowly drop into the three-necked flask solution at room temperature Stir homogeneously, the rotation speed is 3000r / min, the emulsification time is 18min, continue to add 50ml of 2% gum arabic solution, and mix and stir for 10min to form a stable and uniform emulsion.

[0031] (3) Formation of microcapsules: Slowly add 10% glacial acetic acid solution dropwise to the system ...

Embodiment 2

[0034] A whey protein isolate, anionic polysaccharide coated low-boiling point liquid fire extinguishing agent, and a method for preparing fire extinguishing agent microcapsules, comprising the following steps:

[0035] (1) Configuration of the wall material solution: respectively configure a whey protein isolate aqueous solution with a concentration of 2%, and an aqueous carrageenan solution with a concentration of 2%;

[0036] (2) Preparation of emulsion: Measure 50ml of 2% whey protein isolate solution in a three-necked flask, weigh 0.24gspan80 and 2ml of tetrafluorodibromoethane, mix and stir, slowly add it dropwise to the three-necked flask solution at room temperature Stir homogeneously at high speed with a rotation speed of 3000r / min and an emulsification time of 18 minutes. Continue to add 50ml of 2% carrageenan solution and mix and stir for 10 minutes to form a stable emulsion.

[0037] (3) Formation of microcapsules: Slowly add 10% glacial acetic acid solution dropwi...

Embodiment 3

[0040] A whey protein isolate, anionic polysaccharide coated low-boiling point liquid fire extinguishing agent, and a method for preparing fire extinguishing agent microcapsules, comprising the following steps:

[0041] (1) Configuration of the wall material solution: respectively configure a whey protein isolate aqueous solution with a concentration of 2%, and an aqueous gum arabic solution with a concentration of 1%;

[0042] (2) Preparation of emulsion: Measure 50ml of 2% whey protein isolate solution in a three-necked flask, weigh 0.13gspan80 and 1.5ml of trifluorotrichloroethane, mix and stir, then slowly drop into the three-necked flask solution at room temperature Under high-speed homogeneous stirring, the rotation speed is 3000r / min, and the emulsification time is 18min. After the end, add 50ml of 2% gum arabic solution, and mix and stir for 10min to form a stable emulsion.

[0043](3) Formation of microcapsules: Slowly add 10% glacial acetic acid solution dropwise to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com