Preparation method of amorphous nanocrystalline alloy with high magnetic permeability

An amorphous nanocrystalline, high magnetic permeability technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the lack of, unfavorable miniaturization of electronic components, high frequency and miniaturization of power electronic components development obstacles and other issues, to achieve the effect of increasing the magnetic moment reversal speed, which is conducive to high power and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

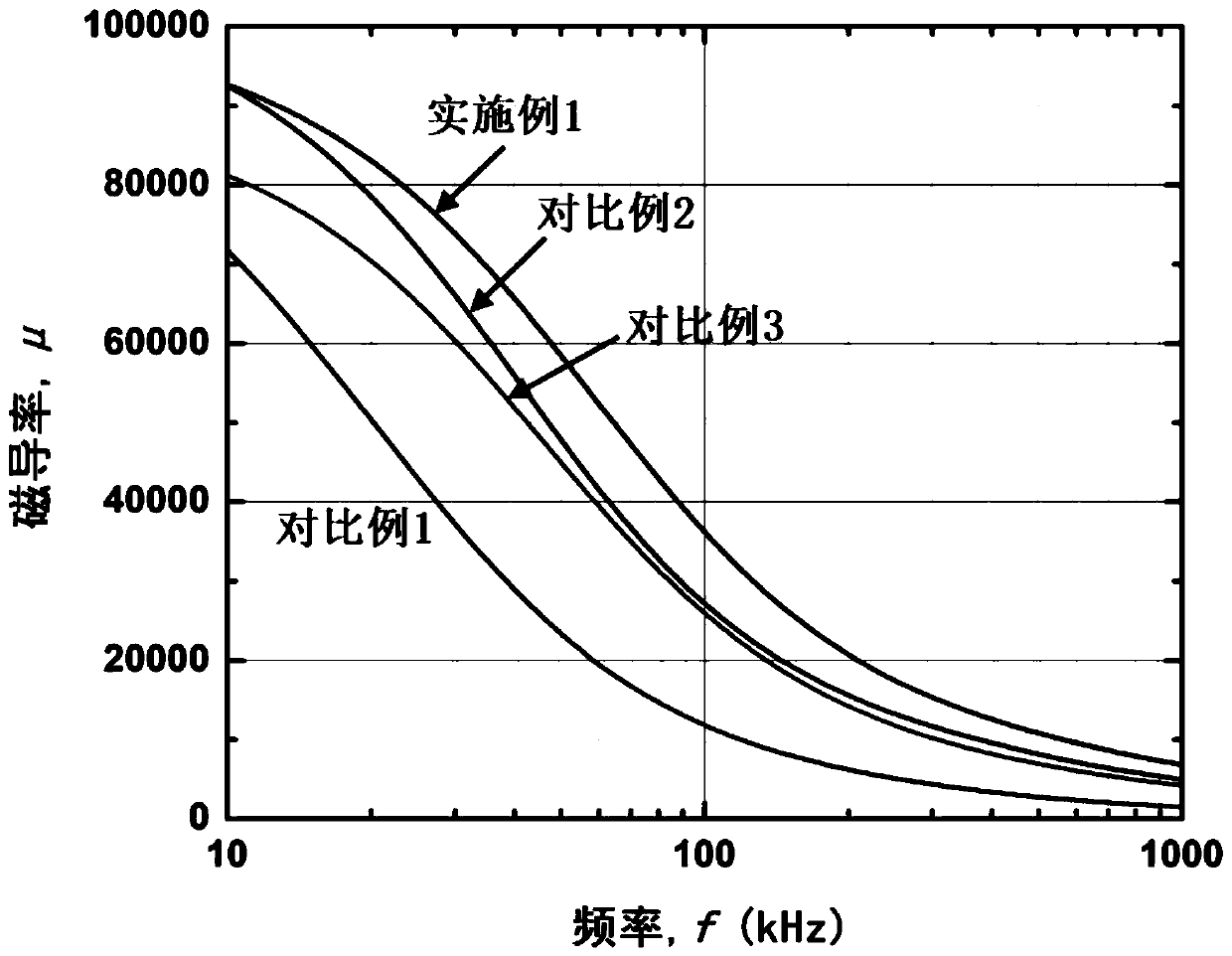

Embodiment 1

[0045] In this embodiment, the composition expression of high magnetic permeability amorphous nanocrystalline alloy is: Fe 76 co 0.2 Si 12.8 B 8 Nb 2 Cu 1 .

[0046] The method and steps for the preparation and heat treatment of the amorphous nanocrystalline alloy are as follows:

[0047] (1) Ingredients: according to the content of various elements in the alloy composition expression, weigh pure iron, pure cobalt, pure silicon, pure copper, boron-iron alloy and niobium-iron alloy with a mass percentage purity of not less than 99%, and prepare this alloy raw materials;

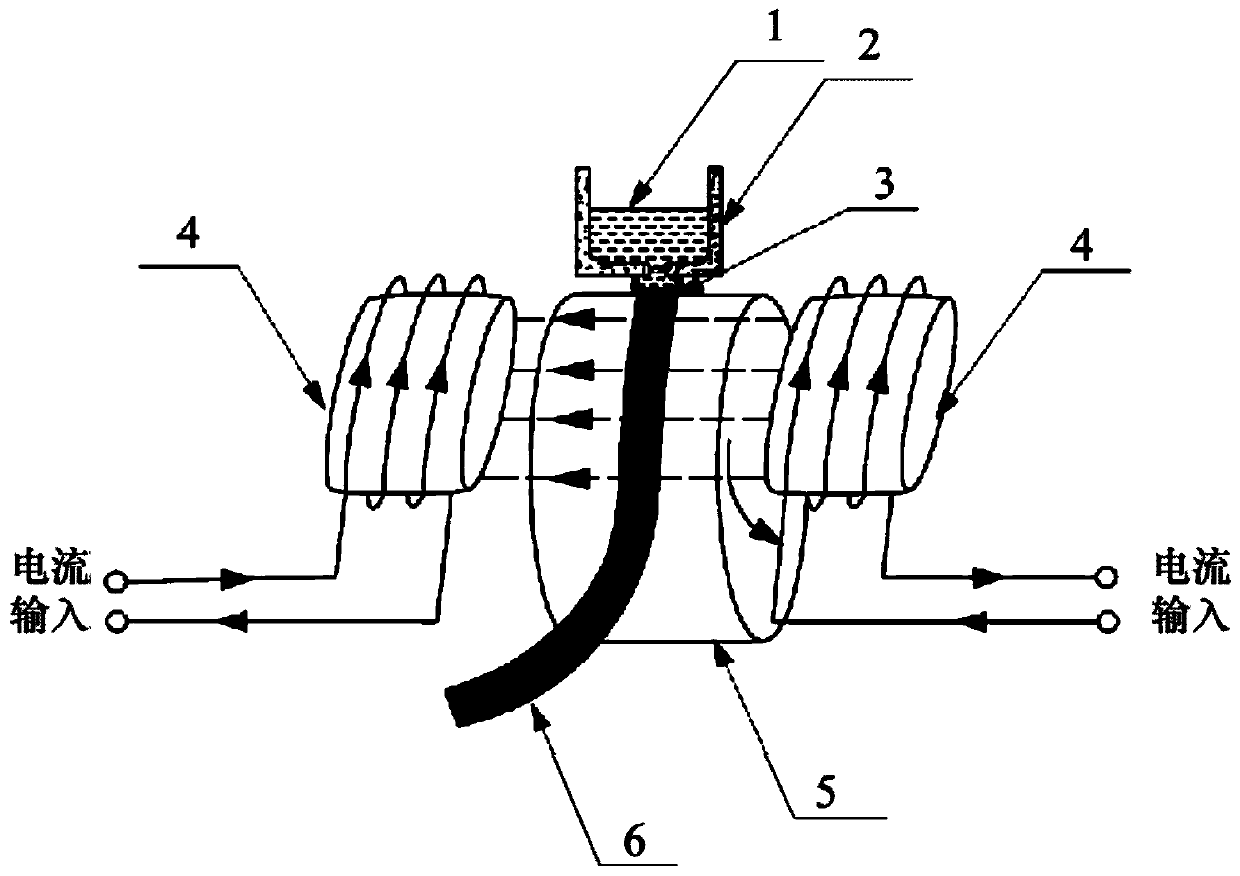

[0048] (2) Smelting master alloy: the raw material of Fe-Co-Si-B-Cu-Nb alloy prepared in step (1) is added in the crucible of vacuum induction melting furnace, evacuated to below 1Pa, energized and heated, and The alloy raw materials are all melted; after all the raw materials are melted, the vacuum is broken and the slag is removed. After the slag is removed, the process of "vacuumizing-smelting-slaggi...

Embodiment 2

[0074] In this embodiment, the composition expression of high magnetic permeability amorphous nanocrystalline alloy is: Fe 78 co 0.5 Si 10 B 8 Nb 2.5 Cu 1 .

[0075] The method and steps of preparation and heat treatment of the amorphous nanocrystalline alloy strip are as follows:

[0076] (1) Ingredients: according to the content of various elements in the alloy composition expression, weigh pure iron, pure cobalt, pure silicon, pure copper, boron-iron alloy and niobium-iron alloy with a mass percentage purity of not less than 99%, and prepare this alloy raw materials;

[0077] (2) Smelting master alloy: the raw material of Fe-Co-Si-B-Cu-Nb alloy prepared in step (1) is added in the crucible of vacuum induction melting furnace, evacuated to below 1Pa, energized and heated, and The alloy raw materials are all melted; after all the raw materials are melted, the vacuum is broken and the slag is removed. After the slag is removed, the process of "vacuumizing-smelting-slagg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com