Crosslinkable and chemically sinterable high-cohesiveness silver nanowire conductive ink and conductive film prepared from same

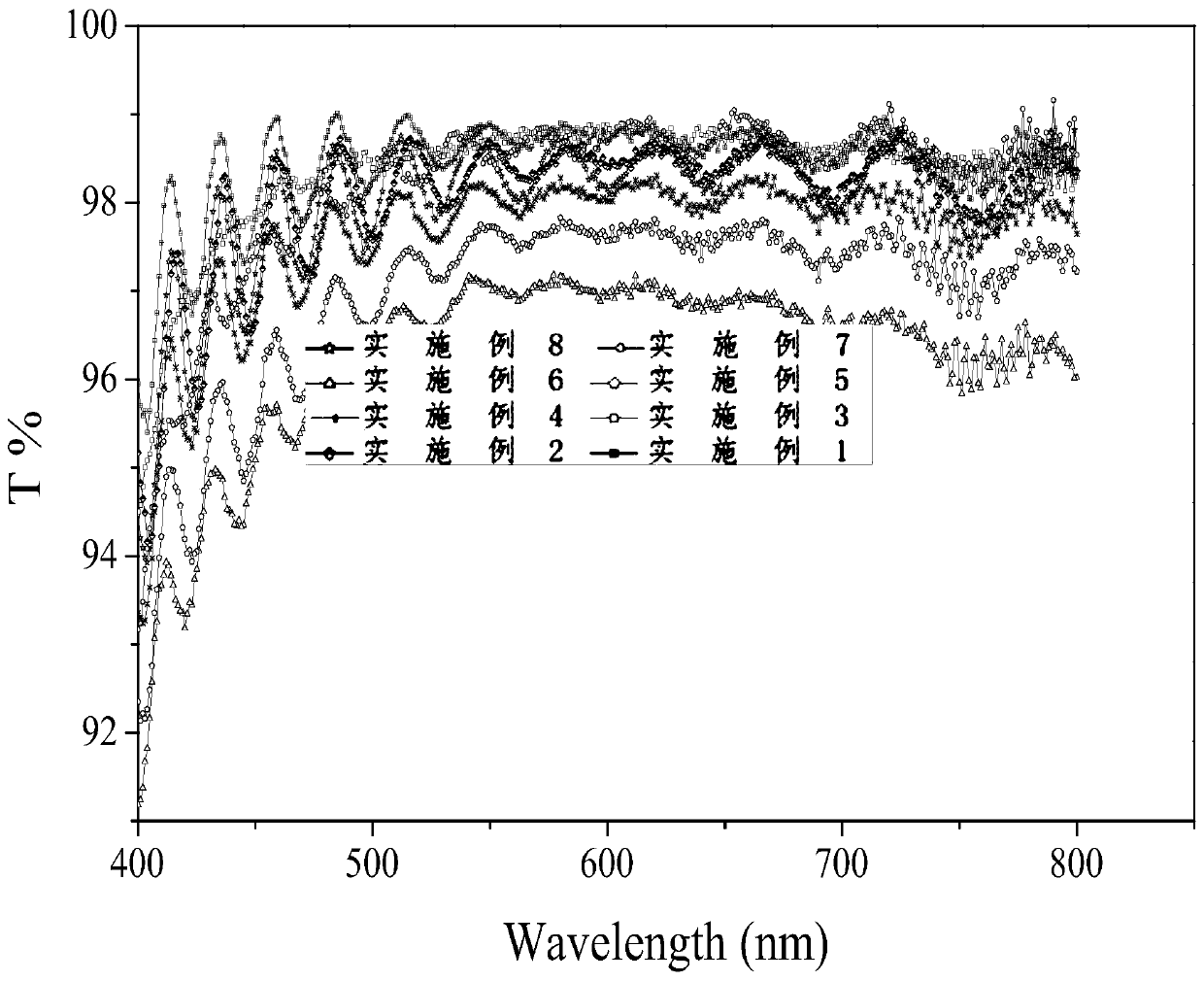

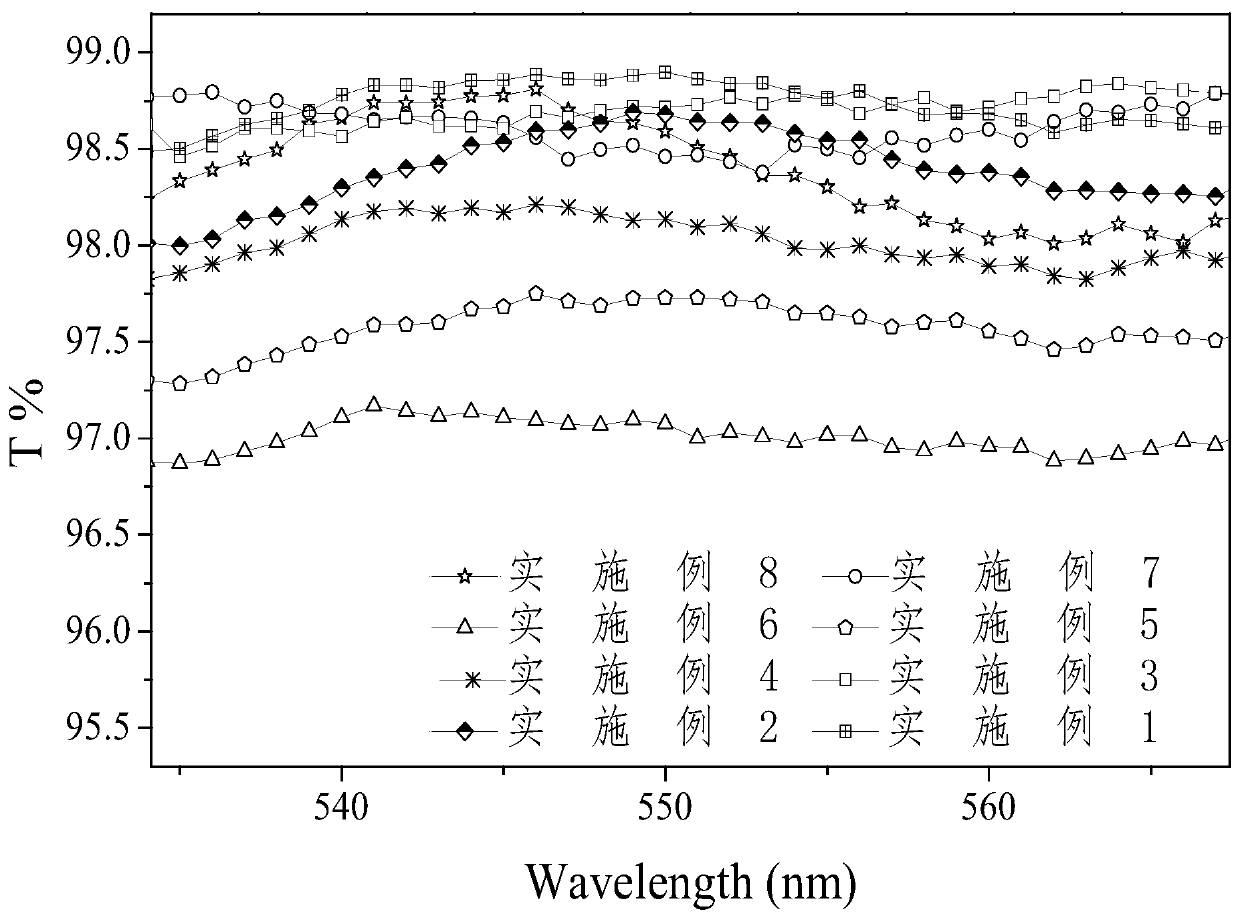

A technology of silver nanowires and conductive inks, which is applied to equipment for manufacturing conductive/semiconductive layers, conductive layers on insulating carriers, cable/conductor manufacturing, etc., can solve the problem of increasing the manufacturing cost of silver nanowire transparent conductive films, Increase the visible light transmittance of the silver nanowire junction resistance, the implementation process is complicated, etc., to achieve the effect of improving the conductivity and visible light transmittance, improving the adhesion, conductivity and visible light transmittance, and the preparation method is simple and easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

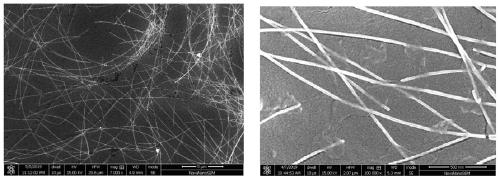

[0036] The preparation and purification of silver nanowires used in the embodiments of the present invention refer to the following two documents:

[0037] Document 1: Dan Jia, Yan Zhao, Wei Wei, Chao Chen, Guowei Lei, Mengjuan Wan, Jingqi Tao, Shuxin Li, Shulin Ji, Changhui Ye, Synthesis of Very Thin AgNanowires with Fewer Particles by Suppressing Secondary Seeding. CrystEngComm2017, 19, 148-153 .

[0038] Document 2: Guinan Chen, Lili Bi, Zhonglin Yang, Liangjun Chen, Guixin Wang, and Changhui Ye, Water-Based Purification of Ultrathin Silver Nanowires toward Transparent Conductive Films with a Transmittance Higher than 99%, ACS Appl. Mater. Interfaces 2019, November, 25 ,22648-22654.

Embodiment 1

[0040] The formula and mass percent of the silver nanowire conductive ink of this embodiment are: 0.5% silver nanowire with a diameter of 20nm and a length of 15-25 μm, 0.15% of an alginic acid binder, and a dispersant of 2-amino-2methyl- 1-propanol 0.005%, leveling agent diacetone alcohol 0.015%, surfactant Triton X-1000.002%, thickener hydroxypropyl methylcellulose 0.3%, defoamer n-heptane 0.08%, crosslinking agent (Chemical sintering agent) calcium chloride 0.002%, solvent water 98.946%.

[0041] The silver nanowire conductive ink of this embodiment can be prepared by mixing all the components evenly.

[0042] The preparation method of the conductive film of the present embodiment is:

[0043] Place a PET base material on the operating table of the automatic coating machine, and make it closely adhere to the operating table through negative pressure;

[0044] Fix the OSP-25 wire rod on the PET, take 1mL conductive ink with a straw, and place it evenly in front of the wire...

Embodiment 2

[0047] The formula and mass percent of the silver nanowire conductive ink of this embodiment are: 0.5% of silver nanowires with a diameter of 20nm and a length of 15-25 μm, 0.45% of alginic acid binder, dispersant 2-amino-2methyl- 1-propanol 0.005%, leveling agent diacetone alcohol 0.015%, surfactant Triton X-1000.002%, thickener hydroxypropyl methylcellulose 0.3%, defoamer n-heptane 0.08%, crosslinking agent (Chemical sintering agent) calcium chloride 0.002%, solvent water 98.646%.

[0048] The silver nanowire conductive ink of this embodiment can be prepared by mixing all the components evenly.

[0049] The preparation method of the conductive film of the present embodiment is:

[0050] Place a PET base material on the operating table of the automatic coating machine, and make it closely adhere to the operating table through negative pressure;

[0051] Fix the OSP-25 wire rod on the PET, take 1mL conductive ink with a straw, and place it evenly in front of the wire rod;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com