A kind of composite catalyst and its preparation method and application

A technology of composite catalyst and hydrogenation reaction, which is applied in the direction of catalytic reaction, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problems of low metal utilization rate, poor reaction selectivity, low metal utilization rate, etc., and increase the load Stability, improved hydrogenation selectivity, and high metal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A second aspect of the present invention provides a preparation method of the above-mentioned composite catalyst, the preparation method comprising the following steps:

[0029] a. Dissolve or disperse the polymer matrix in C 1 -C 4 In the low-carbon alcohol of , obtain the first solution;

[0030] b. Dissolve polybasic acid in C 1 -C 4 In the low-carbon alcohol of , obtain the second solution;

[0031] c. Under stirring, the second solution is added dropwise to the first solution to generate the first precipitation;

[0032] D, the first precipitation produced in step c is separated, obtains solid substance;

[0033] e. Dissolve the salt of the metal active component in C 1 -C 4 In the low-carbon alcohol, the third solution is obtained;

[0034] f, the solid matter obtained in step d is redispersed in C 1 -C 4 In the low-carbon alcohol, the fourth solution is obtained; in a state of stirring, the third solution is added dropwise to the fourth solution to prod...

Embodiment 1

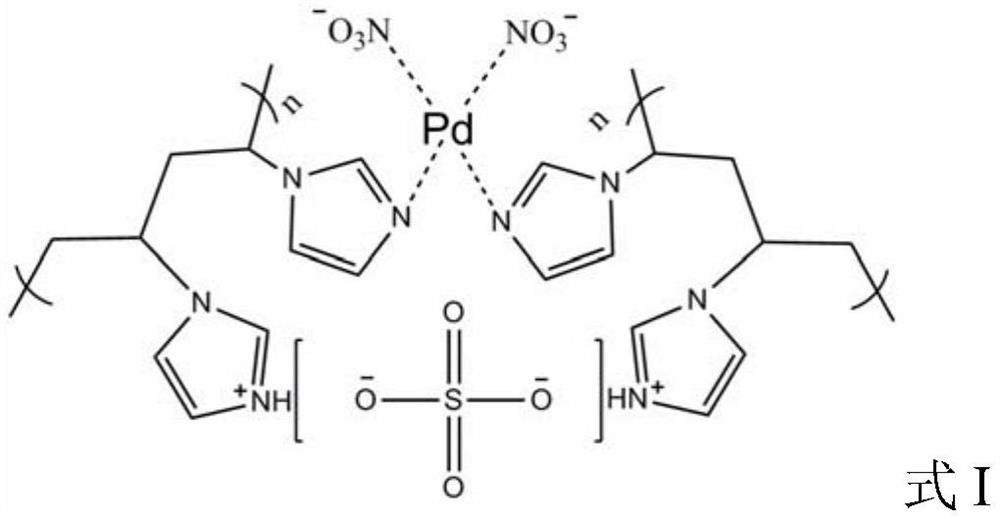

[0047] (1) 20 mmol (1.88 g) of polyvinylimidazole (PVIM) was weighed and dissolved in 200 mL of methanol, and 50 mL of methanol solution with a sulfuric acid concentration of 0.1 mmol / mL was added dropwise under stirring, and a solid substance was immediately produced in the solution. After the dropwise addition was completed, stirring was maintained for 4h. Finally, through vacuum filtration and methanol washing 3 times, the sulfuric acid-polyvinylimidazole complex (H 2 SO 4 -PVIM).

[0048] (2) The H obtained above was 2 SO 4 -PVIM was dispersed in methanol at a concentration of 0.1 g / mL. 10 mL of a methanol solution of palladium nitrate with a palladium concentration of 0.05 mmol / mL was added dropwise with stirring. After the dropwise addition was completed, stirring was maintained for 4 h. Finally, after vacuum filtration and washing with methanol for 3 times, drying at 80 °C for 8 h to obtain a palladium-sulfuric acid-polyvinylimidazole composite catalyst (Pd-H 2 S...

Embodiment 2

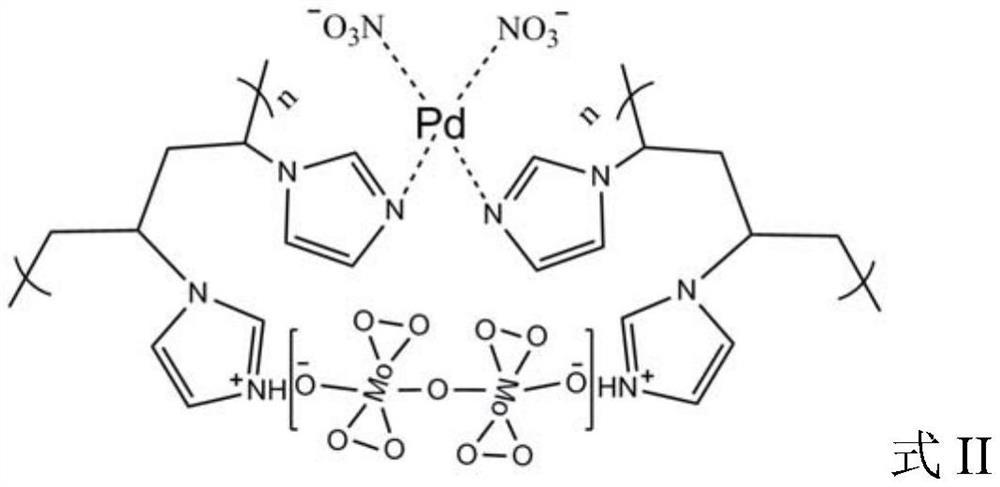

[0052] (1) 20 mmol (1.88 g) of polyvinylimidazole (PVIM) was weighed and dissolved in 200 mL of methanol, and 50 mL of methanol solution with a sulfuric acid concentration of 0.1 mmol / mL was added dropwise under stirring, and a solid substance was immediately produced in the solution. After the dropwise addition was completed, stirring was maintained for 4h. Finally, through vacuum filtration and methanol washing 3 times, the sulfuric acid-polyvinylimidazole complex (H 2 SO 4 -PVIM).

[0053] (2) The H obtained above was 2 SO 4 -PVIM was dispersed in methanol at a concentration of 0.1 g / mL. Take 0.4mL of palladium nitrate methanol solution containing palladium concentration of 0.05mmol / mL, dilute to 20mL with methanol, and add H dropwise under stirring conditions 2 SO 4 -PVIM in methanol. After the dropwise addition was completed, stirring was maintained for 4 h. Finally, after vacuum filtration and washing with methanol for 3 times, drying at 80 °C for 8 h to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com