A kind of phase change energy storage microcapsule with polyurethane modified silicone resin as shell material and preparation method thereof

A technology of polyurethane modification and phase change energy storage, applied in the field of phase change energy storage, can solve the problems of inability to form powder with uniform particle size, injury to operators and users, insufficient toughness of shell materials, etc., and achieve environmental protection, non-toxic production cost, Low production equipment requirements and improved flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

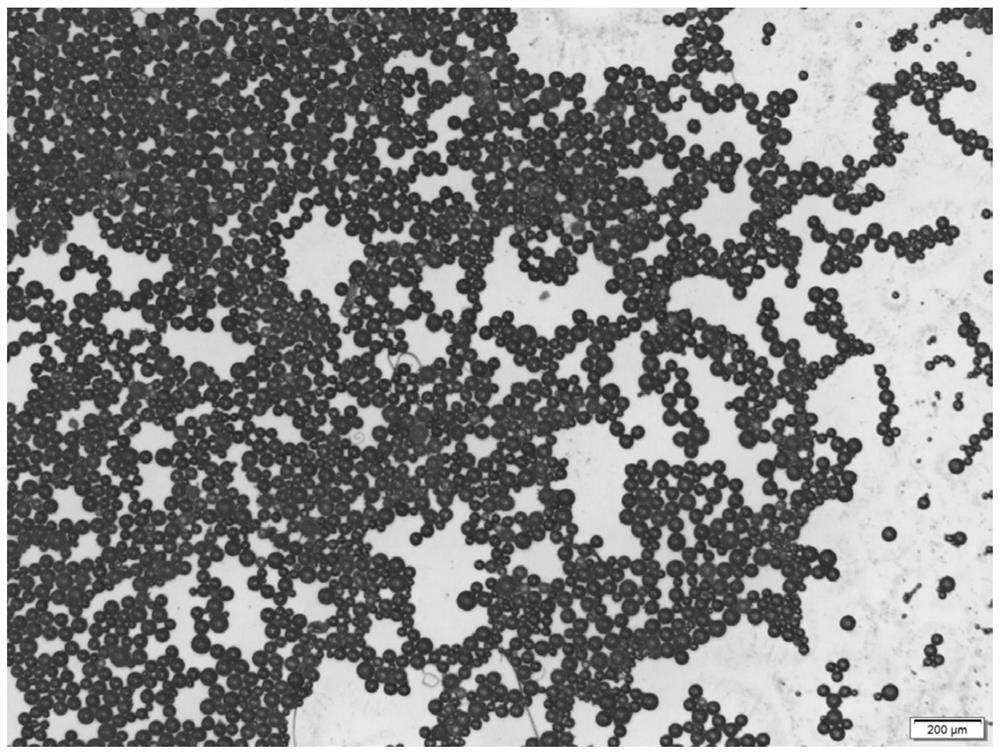

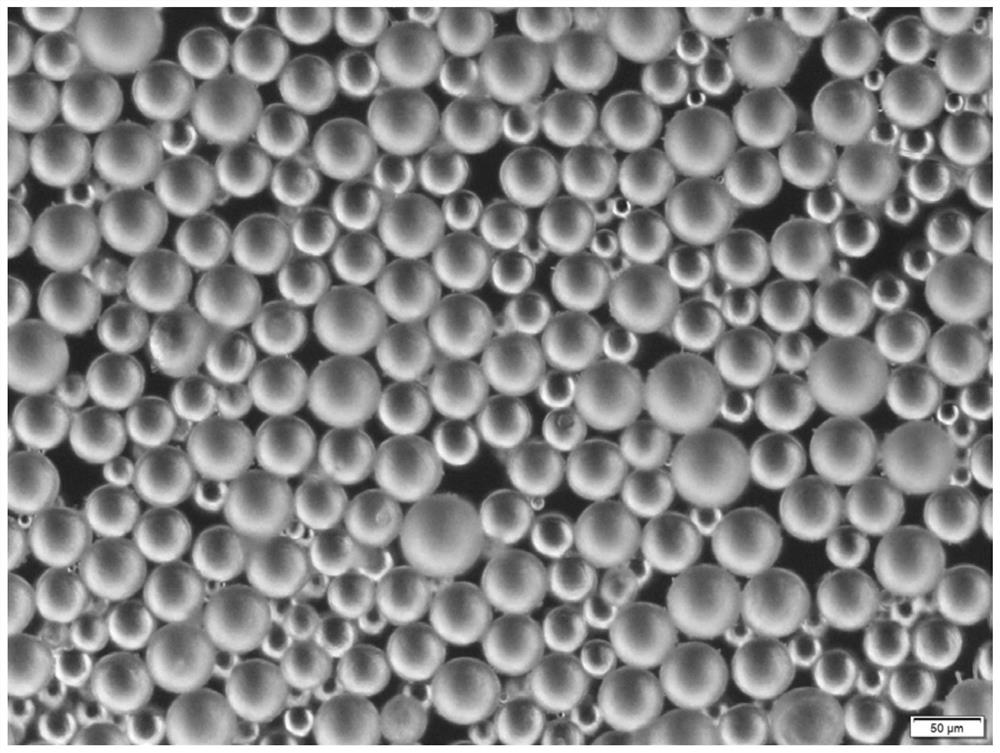

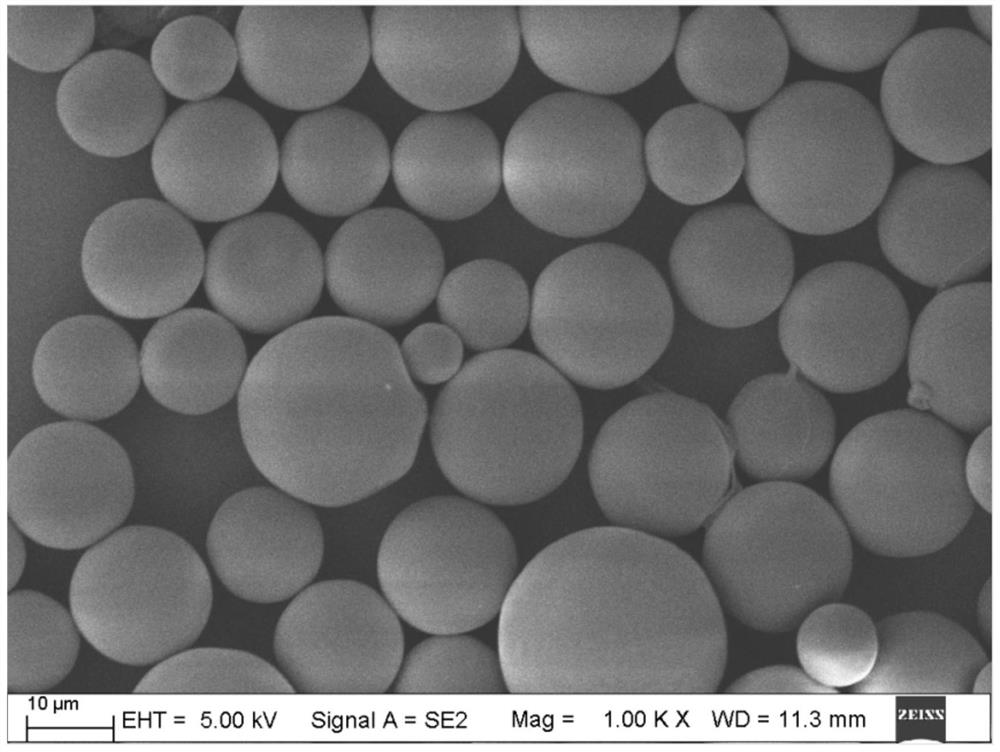

[0059] Example 1 Preparation of phase change energy storage microcapsules with polyurethane modified silicone resin as shell material

[0060] (1) The preparation of polysiloxane prepolymer, the reaction monomer tetramethyl divinyl disiloxane and polymethyl hydrogen siloxane are mixed homogeneously, add the catalyst platinum (0.025% of monomer quality) )-divinyltetramethyldisiloxane complex, prepolymerized in a water bath at a temperature of 60° C. for 45 minutes to prepare 20 grams of polysiloxane prepolymer.

[0061] (2) Preparation of the shell material prepolymer, adding 1 gram of the polyurethane prepolymer into (1), stirring at a constant temperature of 60° C. for 15 minutes to obtain a polyurethane modified silicone resin prepolymer.

[0062] (3) Weigh the core material ethyl laurate with a mass fraction of 4:1 and mix them evenly with the shell material prepolymer for later use.

[0063] (4) Weigh 200 mL of an aqueous solution containing 2% SDS as a surfactant.

[00...

Embodiment 2

[0066] Example 2 Preparation of Phase Change Energy Storage Microcapsules Using Polyurethane Modified Silicone Resin as Shell Material

[0067] (1) The preparation of polysiloxane prepolymer, the reaction monomer tetramethyl divinyl disiloxane and polymethyl hydrogen siloxane are mixed uniformly, add the catalyst platinum (0.03% of monomer mass) )-divinyltetramethyldisiloxane complex, which was prepolymerized in a water bath at a temperature of 55° C. for 40 minutes to prepare 16 grams of polysiloxane prepolymer.

[0068] (2) Preparation of the shell material prepolymer, adding 0.8 g of the polyurethane prepolymer into (1) and stirring evenly, stirring at a constant temperature of 60° C. for 15 minutes to obtain a polyurethane modified silicone resin prepolymer.

[0069] (3) Weigh the core material methyl behenate with a mass fraction of 4.5:1 and mix them evenly with the shell material prepolymer for later use.

[0070] (4) Weigh 200 mL of an aqueous solution containing 2% S...

Embodiment 3

[0073] Example 3 Preparation of Phase Change Energy Storage Microcapsules Using Polyurethane Modified Silicone Resin as Shell Material

[0074] (1) For the preparation of polysiloxane prepolymer, the reaction monomer tetramethyldivinyl disiloxane and polymethylhydrogensiloxane are mixed evenly in a certain proportion, and 0.05% of the monomer mass is added Dibutyltin dilaurate was prepolymerized in a water bath at a temperature of 70° C. for 35 minutes to prepare 30 grams of polysiloxane prepolymer.

[0075] (2) Preparation of the shell material prepolymer, adding 2 grams of polyurethane prepolymer into (1), stirring and mixing, and stirring at a constant temperature of 60° C. for 15 minutes to obtain a polyurethane modified silicone resin prepolymer.

[0076] (3) Weigh the core material n-octadecane with a mass fraction of 5:1 and mix them evenly with the shell material prepolymer for later use.

[0077] (4) Weigh 200 mL of an aqueous solution containing 7% PVA as a surfacta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com