Design and preparation method of air cooler steel-based aluminum finned tube bundle anti-scaling nano composite coating

A nano-composite, aluminum fin technology, applied in design optimization/simulation, coating, liquid chemical plating, etc., can solve the problem that the heat dissipation efficiency of finned tubes is greatly affected, the fins are easy to absorb dust particles, and reduce air-condensed vapor. To solve problems such as device efficiency, achieve excellent anti-fouling performance, reduce corrosion and aging rate, and save labor and material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

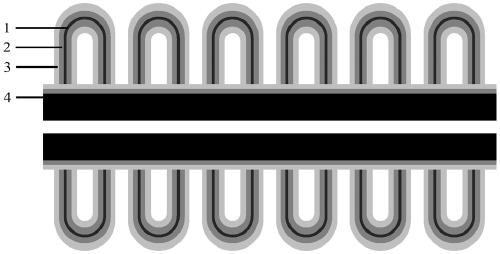

[0085] refer to figure 2 , the steel-based aluminum finned tube bundle of the air cooler consists of a serpentine coil 1, a Ni-P bottom layer 2, a Ni-P-PTFE nanoparticle surface layer 3 or Ni-P-SiO 2 Nano particle surface layer, carbon steel base pipe 4 composition.

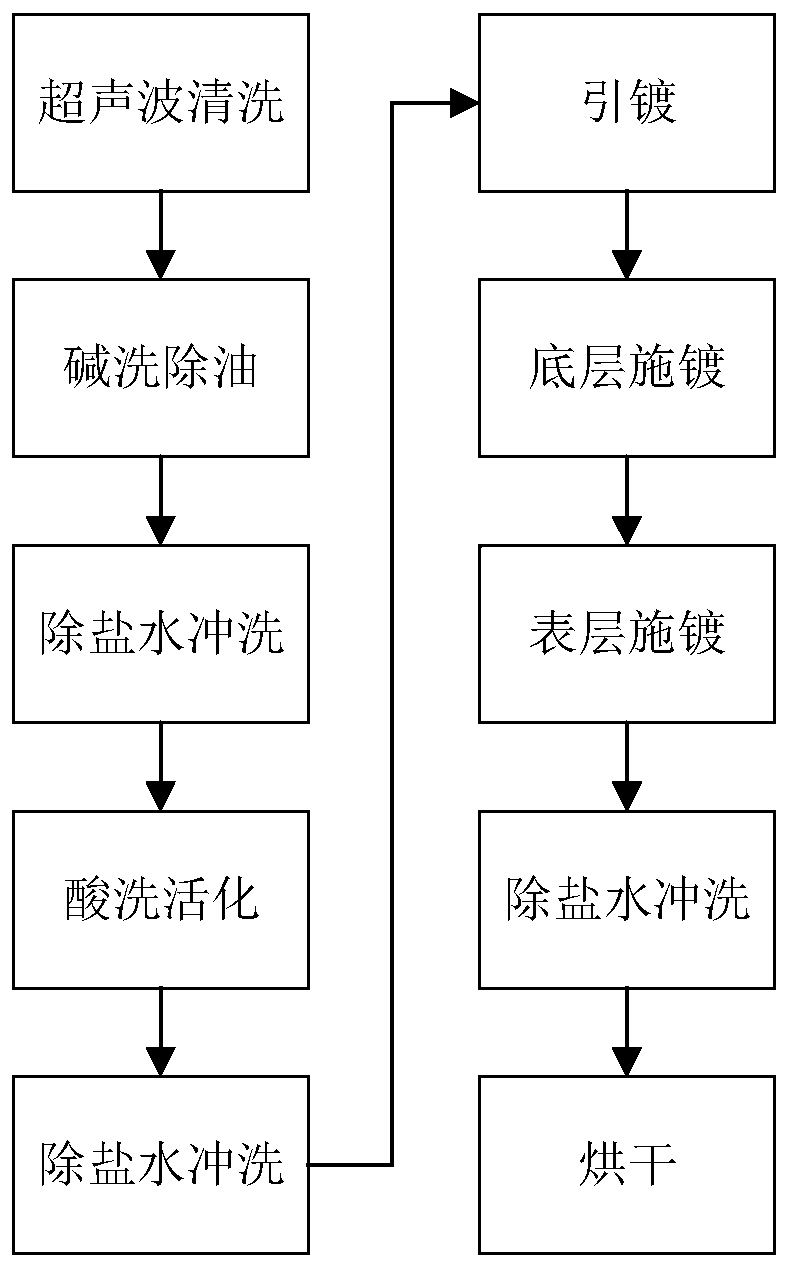

[0086] refer to figure 1 and figure 2 , Preparation of anti-fouling nanocomposite coatings on steel-based aluminum finned tube bundles of air coolers

[0087] Step 1: Select an ultrasonic instrument with an ultrasonic frequency of 40K HZ and a power of 160W to clean the steel-based aluminum finned tube bundle sample for 1 to 2 hours, and extend the time appropriately until the surface rust, floating ash and other attachments are completely removed , After cleaning, rinse with water and dry with cold air for later use.

[0088] Step 2: Alkaline washing and degreasing. Alkaline washing is performed on the steel-based aluminum finned tube bundles of the air cooler in a constant temperature water bath at 60-75°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com