Ceramic piston rod and ceramic coating spraying process

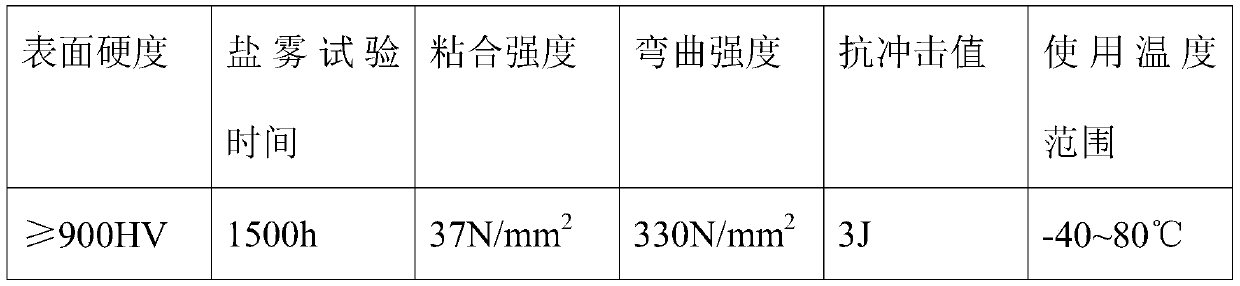

A technology of ceramic coating and piston rod, applied in metal material coating process, piston rod, coating, etc., can solve the problems of hardness, wear resistance, friction coefficient, insufficient life, etc., to improve the bonding strength and bending Strength and impact resistance value, anti-oxidation effect of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

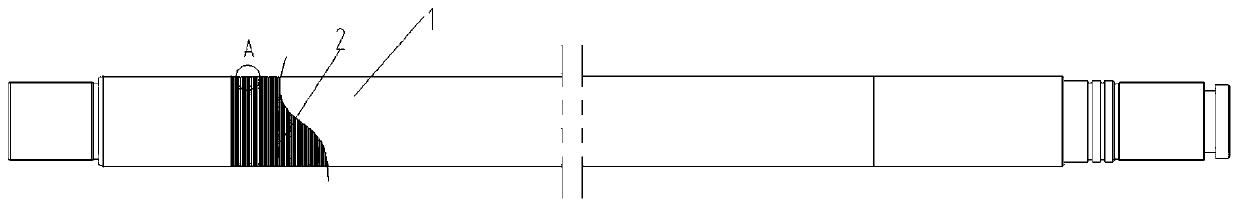

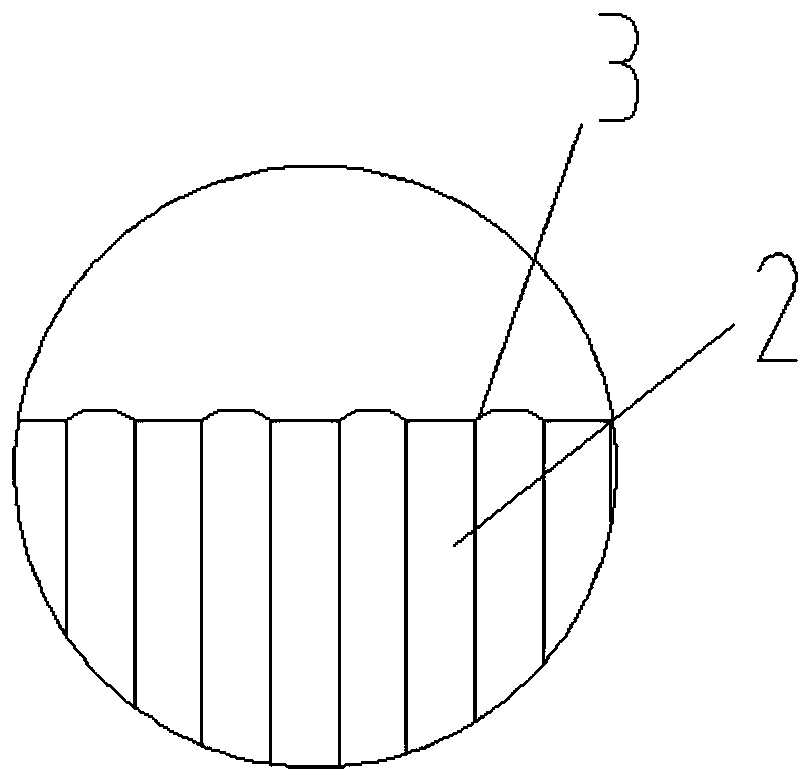

[0021] like Figure 1~2 As shown, a ceramic piston rod disclosed by the present invention sprays a ceramic coating on the surface of the piston rod body 1, and the surface of the piston rod body under the ceramic coating is processed with signal grooves 2 with equal thread spacing to form a detection section, and the signal groove groove There is a 45° chamfer 3 on the outside of the mouth, and the width of the chamfer is 1 / 6 of the width of the notch. The ceramic coating sprayed in the signal groove is flush with the surface of the ceramic coating outside the groove to form an integral body. The ceramic coating I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com