Medical copper-containing composite coating and preparation method thereof

A composite coating and coating technology, applied in the field of medical materials, can solve the undisclosed coating thickness, copper content and biocompatibility synergistic relationship, antibacterial composite copper-containing coating has no clear coating structure, undisclosed copper Content control technology and preparation methods and other issues, to achieve good blood compatibility, avoid damage, and ensure the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In order to solve the second technical problem of the present invention, the preparation method of the medical copper-containing composite coating comprises:

[0044] A. Start glowing under an argon atmosphere of 0.8-2.0Pa, then stabilize the pressure at 1-1.5Pa, and deposit it on the substrate by sputtering only through argon gas. The power of the sputtering deposition is 40-100W. The substrate bias of sputtering deposition is 40-100V; wherein, the time of sputtering deposition with only argon gas is preferably 10min;

[0045] B. Infuse nitrogen again, adjust the flow rate of nitrogen and argon to make the ratio of nitrogen and argon 1:8 to 1:1, open the high-purity copper target and high-purity titanium target and continue sputtering deposition on the substrate for 10 to 40 minutes to obtain medical containing Copper composite coating.

[0046] Preferably, the substrate is medical stainless steel, high-purity titanium, titanium alloy, nickel-titanium alloy, pure iron...

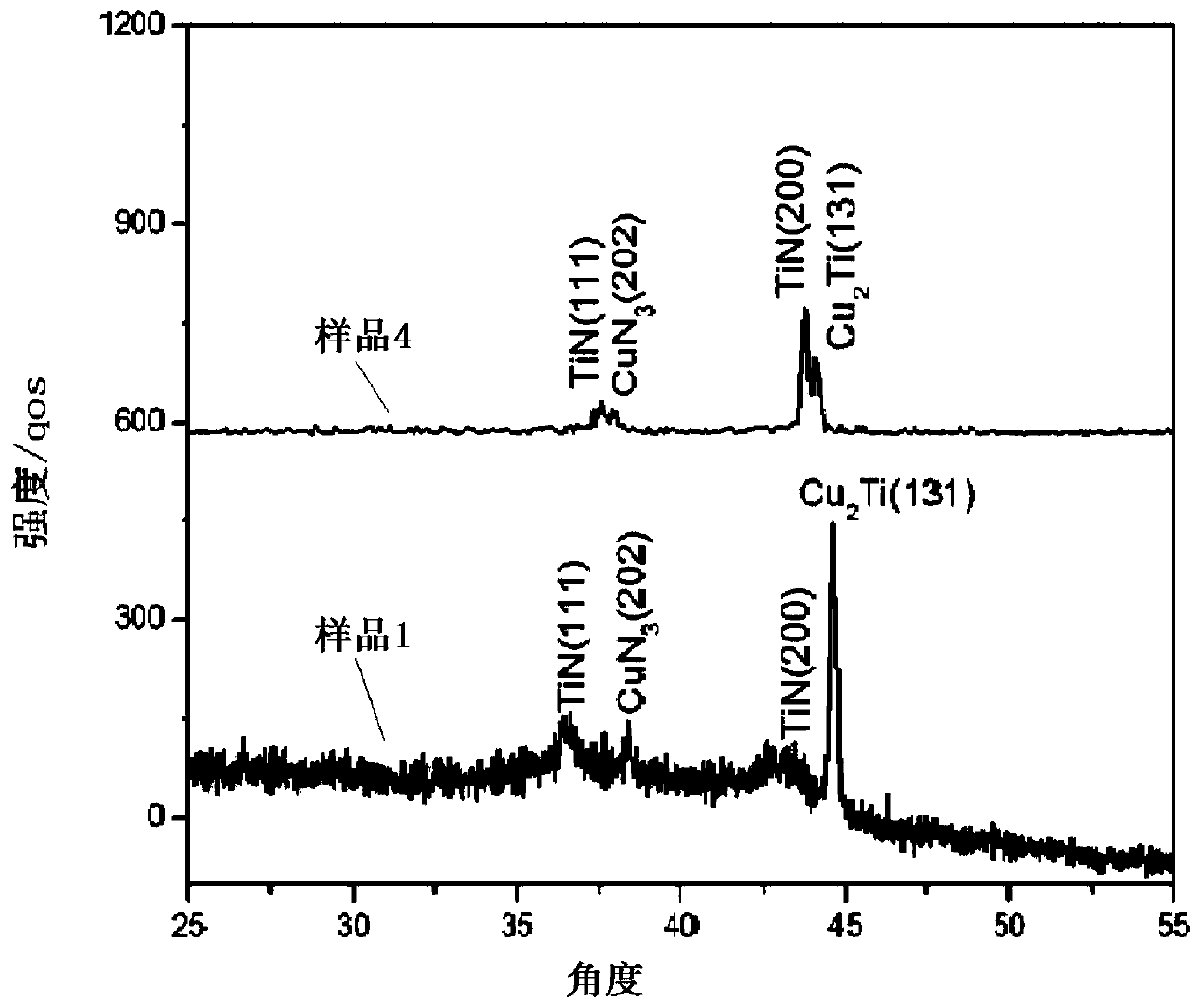

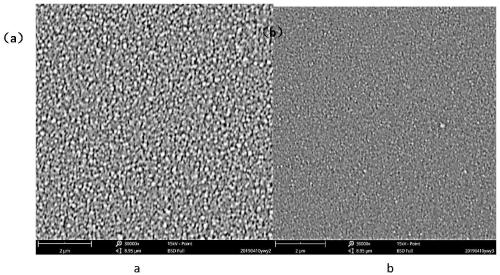

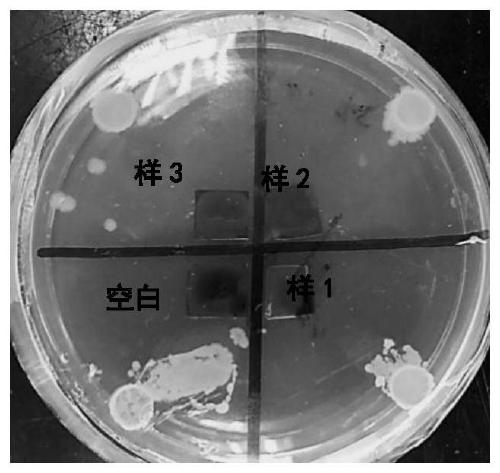

Embodiment 1~4

[0053] Pump the vacuum in the chamber of the sputtering furnace to 6.0×10 -4 Pa, the temperature of the medical nickel-titanium substrate is heated to the temperature shown in Table 1, and the argon gas with a purity of 99.99% is introduced, and the chamber pressure is adjusted for backsputtering for 15 minutes, and then the flow rate of the argon gas is adjusted so that the air pressure in the chamber of the sputtering furnace is Carry out the glow operation at about 1Pa. After the glow is completed, stabilize the air pressure at 1Pa, adjust the sputtering power to the value required in Table 1, add the substrate bias voltage of 70V, and only pass argon gas for sputtering deposition for 10 minutes, so that the substrate has a good The binding force, and then through the nitrogen sputtering 20min Cu / Ti-N composite coating on the substrate. And the Cu / Ti-N composite coating was prepared by adjusting the flow rate of nitrogen and argon to adjust the nitrogen-argon ratio to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com