High alkali resistance 1,1-diofluoroethylene polymer and preparation method

A difluoroethylene, alkali-resistant technology, applied in the field of high alkali-resistant 1,1-difluoroethylene polymer and its preparation, can solve the problem of reducing the temperature range of the copolymer, reducing the rigidity of PVDF, wear resistance and hardness Decrease and other problems, to achieve the effect of controllable efficiency, increased mode, and improved strong alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

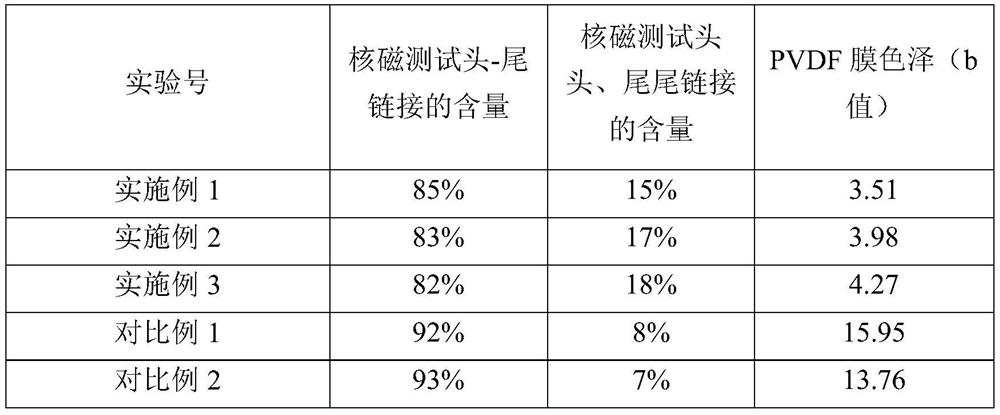

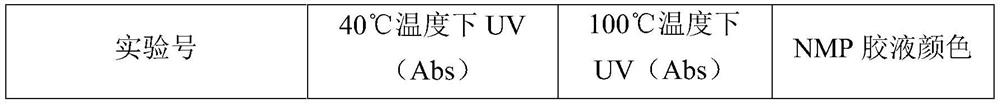

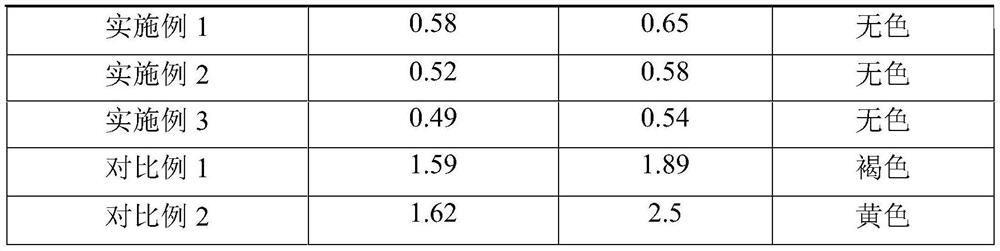

Examples

Embodiment 1

[0027] In a 100L vertical reactor, add 50L of deionized water, 74.25g of polyvinyl alcohol dispersant, 0.75g of calcium hydroxyphosphate as the inorganic dispersant, 150g of ethyl acetate, 300g of disodium hydrogen phosphate, close the reactor, and use Nitrogen was purged for 30 minutes until the oxygen content in the reactor was less than 20ppm. Then start stirring, raise the temperature in the reactor to 80° C., add vinylidene fluoride monomer until the pressure in the reactor reaches 6 MPa, and add 10 g of initiator potassium persulfate to start the reaction. Continue to add vinylidene fluoride monomer to maintain the pressure, and add 2 g of potassium persulfate every half an hour until the amount of VDF monomer added reaches 15000 g, and maintain the temperature to consume residual monomer. Stop stirring after 30 min, vent to normal pressure, and collect the product after post-treatment.

Embodiment 2

[0029] In a 100L vertical reactor, add 50L of deionized water, 112.5g of polyvinyl alcohol dispersant, 15g of calcium hydroxyphosphate as an inorganic dispersant, 3g of ammonium carbonate, and 150g of ethyl acetate, close the reactor, and purge with nitrogen 30min until the oxygen content in the reactor is less than 20ppm. Then start stirring, raise the temperature in the reactor to 95° C., add vinylidene fluoride monomer until the pressure in the reactor reaches 6 MPa, and add 10 g of initiator potassium persulfate to start the reaction. Continue to add vinylidene fluoride monomer to maintain the pressure, and add 2 g of potassium persulfate every half an hour until the amount of VDF monomer added reaches 15000 g, and maintain the temperature to consume residual monomer. Stop stirring after 30 min, vent to normal pressure, and collect the product after post-treatment.

Embodiment 3

[0031] In a 100L vertical reactor, add 50L of deionized water, 150g of polyvinyl alcohol dispersant, 22.5g of calcium hydroxyphosphate as an inorganic dispersant, 3g of ammonium carbonate, and 150g of ethyl acetate, close the reactor, and purge with nitrogen 30min until the oxygen content in the reactor is less than 20ppm. Then start stirring, raise the temperature in the reactor to 90° C., add vinylidene fluoride monomer until the pressure in the reactor reaches 6 MPa, and add 10 g of initiator potassium persulfate to start the reaction. Continue to add vinylidene fluoride monomer to maintain the pressure, and add 2 g of potassium persulfate every half an hour until the amount of VDF monomer added reaches 15000 g, and maintain the temperature to consume residual monomer. Stop stirring after 30 min, vent to normal pressure, and collect the product after post-treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com