Automatic edge grinding machine

A sanding machine, automatic technology, applied to machine tools, grinding feed motion, grinding drive devices and other directions suitable for grinding workpiece edges, can solve problems such as low grinding efficiency, worker injury, and large number of workers, etc. The effect of improving processing efficiency and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

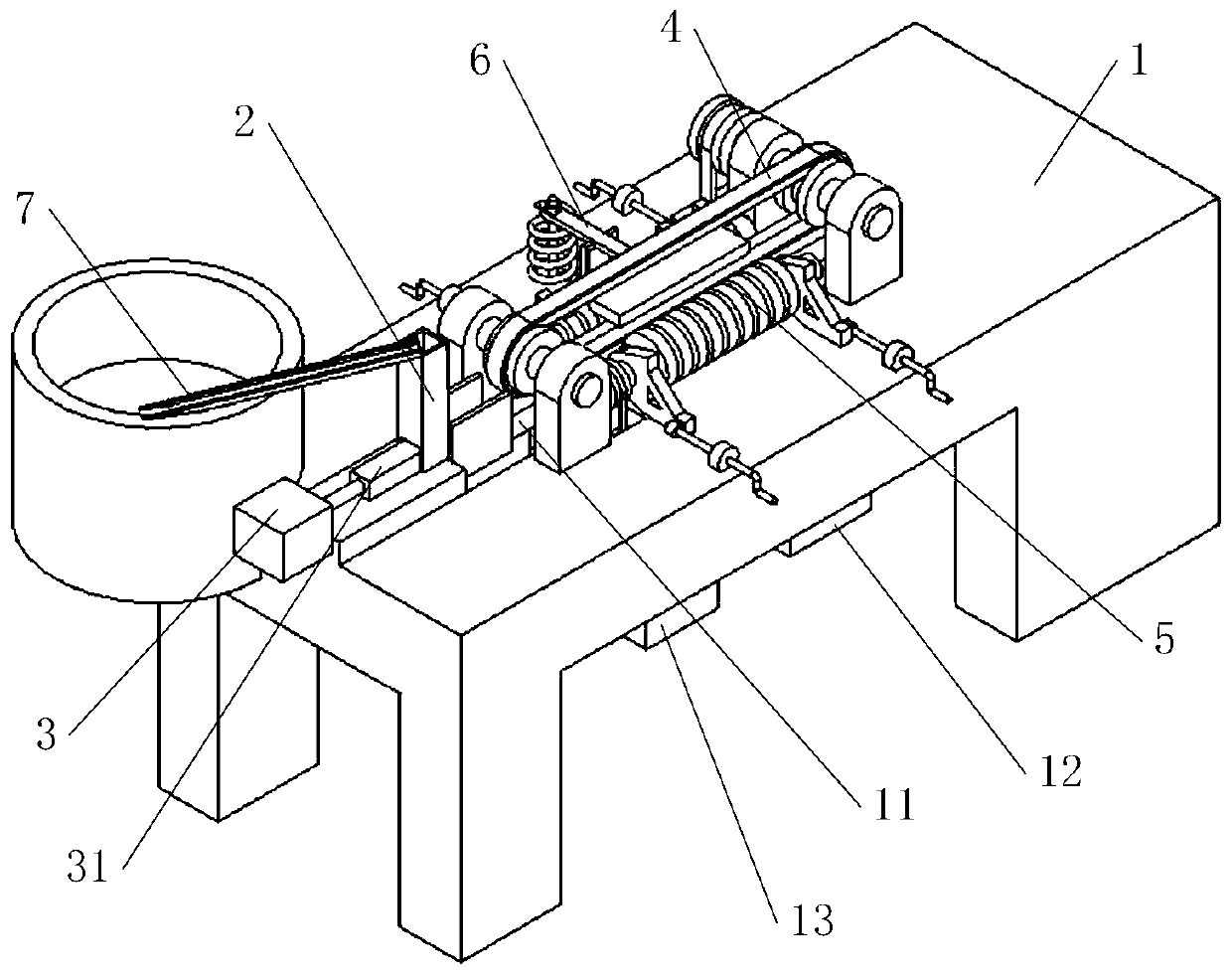

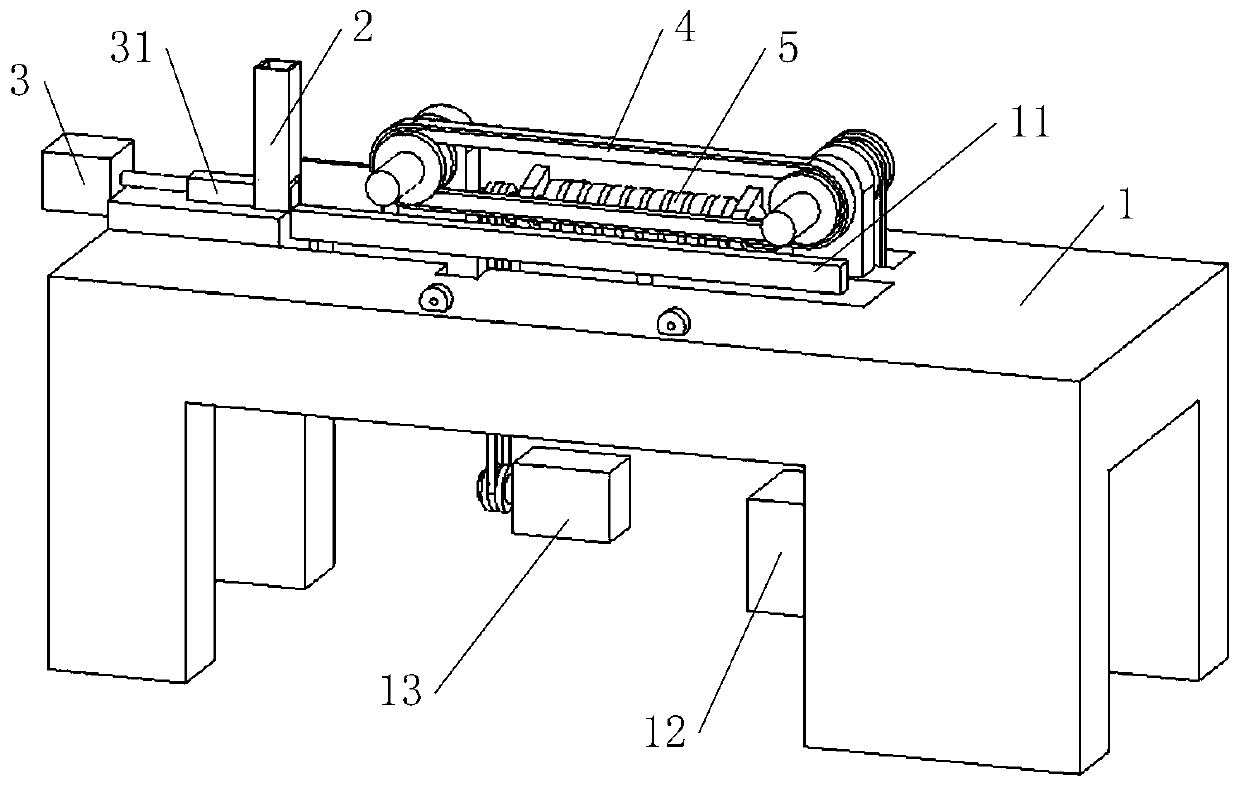

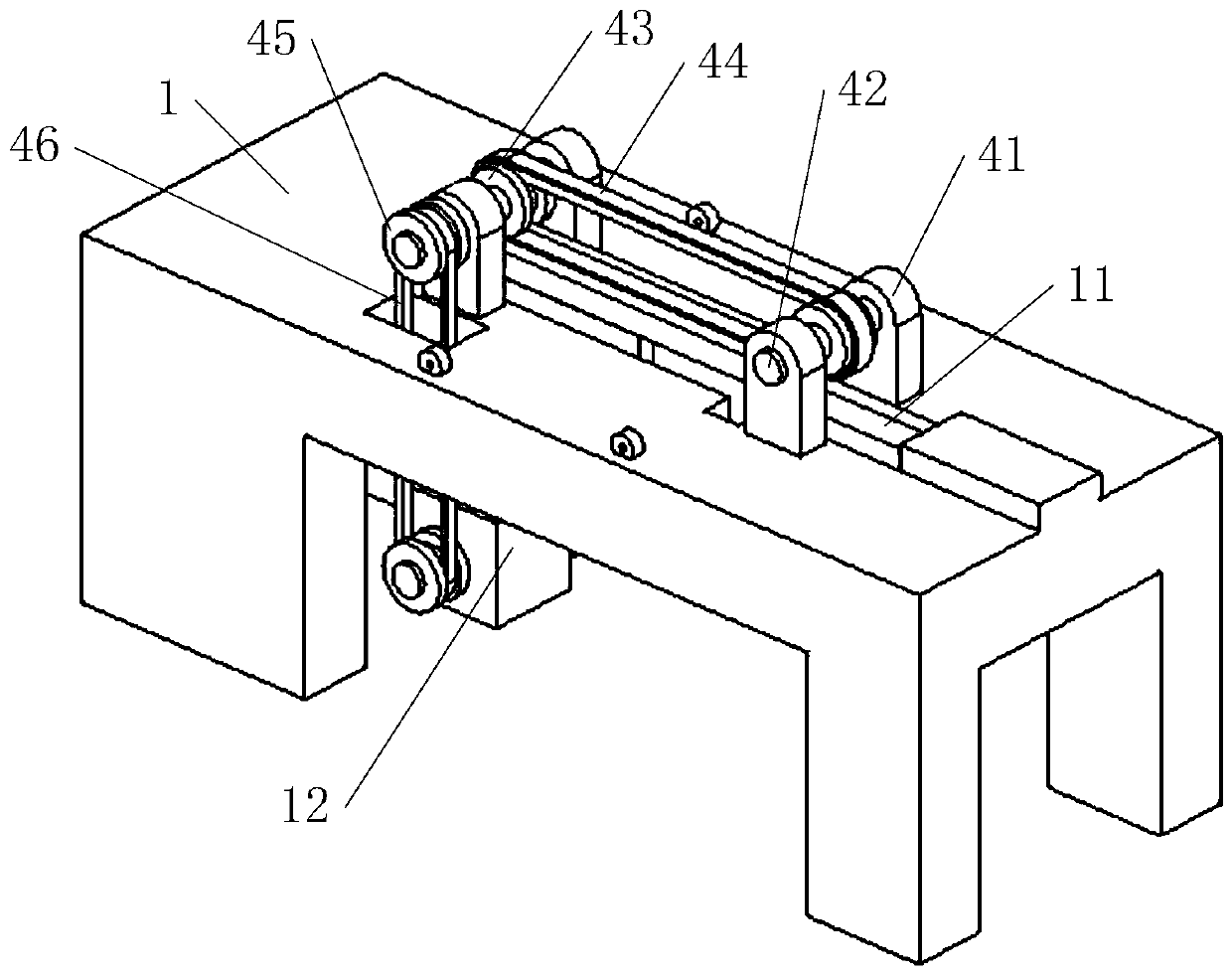

[0025] like Figure 1 to Figure 5 As shown, the automatic edge sanding machine provided in this embodiment includes a frame 1, a feed pipe 2, a pusher cylinder 3, a pressing device 4 and a sand edge device 5, and a vertical feeder is provided on one side of the frame 1. Feeding pipe 2, the cross section of the feeding pipe 2 is rectangular, used to prevent the metal rubber ring from rotating in the feeding pipe 2, and a directional vibrating plate 7 matching the inlet of the feeding pipe 2 is provided on one side of the frame 1 , the frame 1 below the feed pipe 2 is equipped with a horizontally arranged pusher cylinder 3, the feed pipe 2 is provided with a photoelectric sensor for detecting metal rubber rings, and the photoelectric sensor is connected to the pusher cylinder through an existing connection method. 3 connection, used to control the start of the pusher cylinder 3, the piston rod of the pusher cylinder 3 is provided with a pusher block 31 that matches the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com