Preparation method of small-hole thread made of high-volume-fraction aluminum-based silicon carbide composite material

An aluminum-based silicon carbide, high volume fraction technology, applied in the field of precision machining and precision machining of composite materials, can solve the problem that the thread cannot adapt to repeated disassembly, and achieves the effect of saving processing cost, uniform coating thickness, and improving the strength of the thread.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

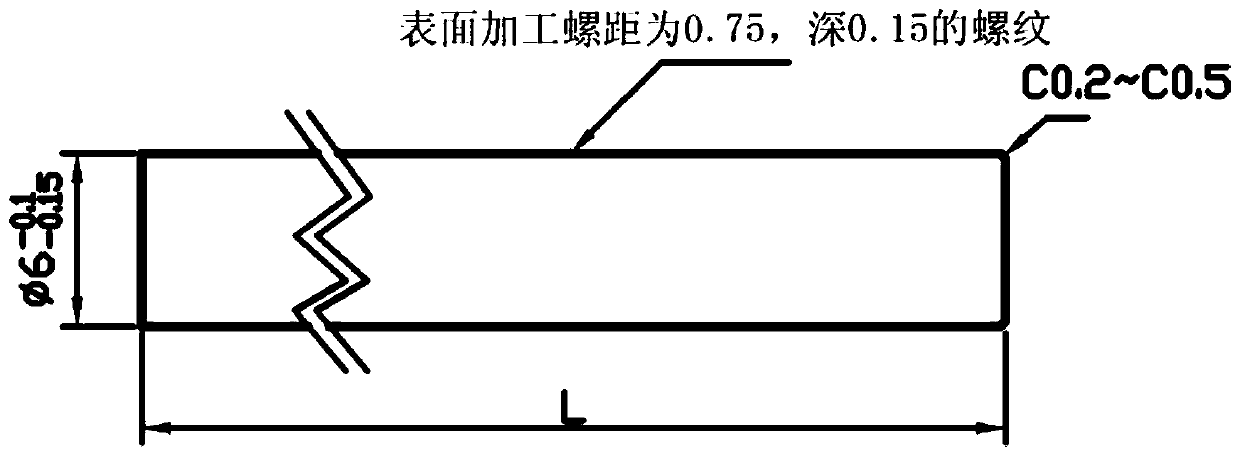

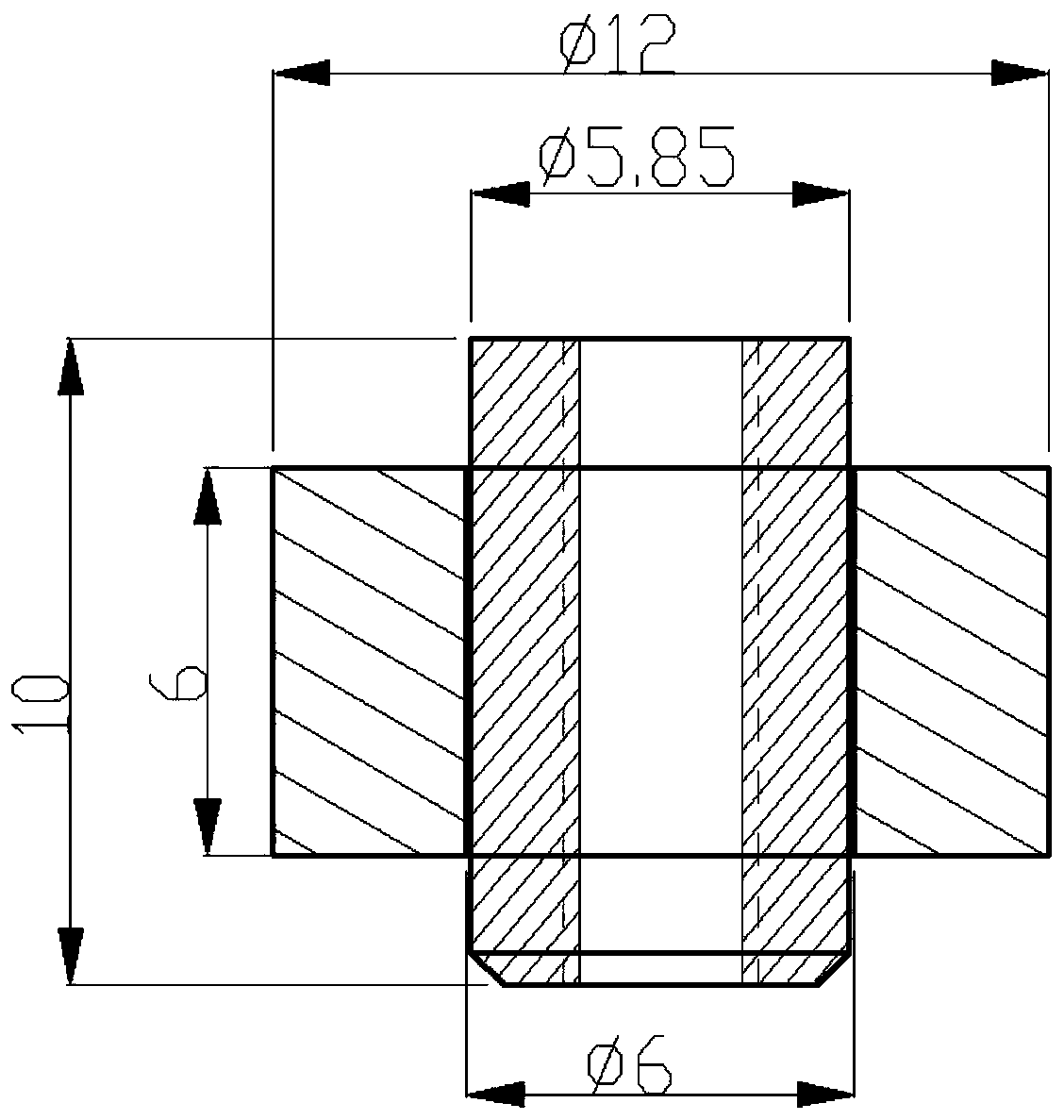

[0043]The invention provides a method for processing threads on a high volume fraction aluminum-based silicon carbide composite material. Process M2, M2.5, M3, M4, M5, M6 and other internal threads on aluminum-based silicon carbide materials with a volume fraction above 55%, control the processing size and accuracy of pin titanium alloy columns, and process on aluminum-based silicon carbide materials According to the technical requirements of the inner hole, the implementation of the brazing process, and the quality inspection and control of the processed threaded hole, finally realize the processing of M2, M2.5, M3, M4, M5, M6, etc. on high-volume aluminum-based silicon carbide materials Internal thread, and meet its repeated disassembly and connection strength requirements.

[0044] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] (1) if figure 1 As shown, the aluminum-based silicon ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com