A kind of preparation method of high stability artificial solid electrolyte interface membrane material

A solid electrolyte, high stability technology, applied in electrolyte layer coating, electrode manufacturing, circuit, etc., can solve the problems of poor thermal stability, safety performance needs to be improved, etc., achieve good mechanical properties, slow down the shuttle effect, prevent the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

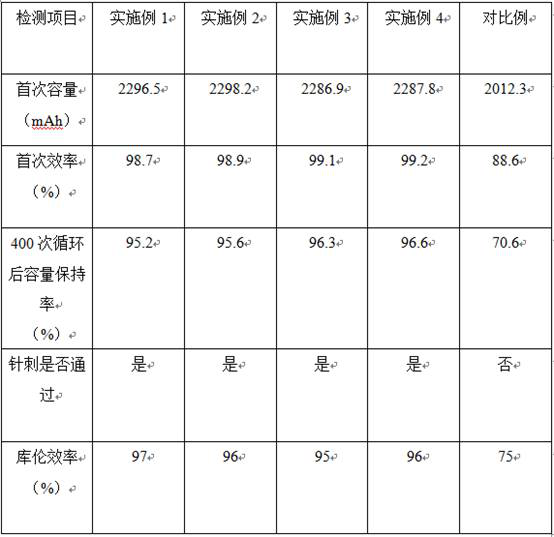

Examples

Embodiment 1

[0028] According to the mass ratio of 1:15, add tantalum ethoxide to high-purity water, stir and mix to obtain a high-purity tantalum ethoxide aqueous solution, and then according to a volume ratio of 1:1, stir and mix absolute ethanol and tantalum ethoxide high-purity aqueous solution and place at 55°C Under the heat preservation reaction for 25 minutes, the heat preservation reaction solution was obtained and added dropwise to the heat preservation reaction solution according to the mass fraction of 5% ammonia water, and the pH was adjusted to 8.5. After the heat preservation reaction for 25 minutes, it was left to cool to room temperature and filtered. After rinsing for 3 times, vacuum-dry at 75°C for 20 hours, collect the dried matrix particles and place them in a muffle furnace, raise the temperature to 750°C at a rate of 5°C / min, heat-preserve and calcinate for 2 hours, and grind through a 200-mesh sieve to obtain matrix particles; According to the mass ratio of 1:1, lith...

Embodiment 2

[0030] According to the mass ratio of 1:15, add tantalum ethoxide to high-purity water, stir and mix to obtain a high-purity tantalum ethoxide aqueous solution, and then according to a volume ratio of 1:1, stir and mix absolute ethanol and tantalum ethoxide high-purity aqueous solution and place at 57°C Under the heat preservation reaction for 27 minutes, the heat preservation reaction solution was obtained and added dropwise to the heat preservation reaction solution according to the mass fraction of 5% ammonia water, and the pH was adjusted to 8.5. After the heat preservation reaction for 27 minutes, it was left to cool to room temperature and filtered, and the filter cake was collected and deionized water After washing for 4 times, vacuum dry at 77°C for 22 hours, collect the dried matrix particles and place them in a muffle furnace, raise the temperature to 800°C at a rate of 5°C / min, heat-preserve and calcinate for 2.5 hours, and grind through a 200-mesh sieve to obtain mat...

Embodiment 3

[0032] According to the mass ratio of 1:15, add tantalum ethoxide to high-purity water, stir and mix to obtain tantalum ethoxide high-purity aqueous solution, and then according to the volume ratio 1:1, stir and mix absolute ethanol and tantalum ethoxide high-purity aqueous solution and place at 58°C Under the heat preservation reaction for 28 minutes, the heat preservation reaction solution was obtained and added dropwise to the heat preservation reaction solution according to the mass fraction of 5% ammonia water, and the pH was adjusted to 8.5. After the heat preservation reaction for 28 minutes, it was left to cool to room temperature and filtered. After washing 4 times, vacuum dry at 78°C for 23 hours, collect the dried matrix particles and place them in a muffle furnace, raise the temperature to 835°C at a rate of 5°C / min, heat-preserve and calcinate for 2.5 hours, and grind through a 200-mesh sieve to obtain matrix particles; Then, according to the mass ratio of 1:1, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com