Novel process structure and binding method for short-circuit resistance electrodynamic force of transformer winding

A transformer winding and anti-short-circuit technology, which is applied to transformer/inductor parts, transformer/inductor coil/winding/connection, inductor/transformer/magnet manufacturing, etc. Power increase and other problems, to achieve the effect of not affecting electrical performance and temperature rise, simple structure and method, and outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

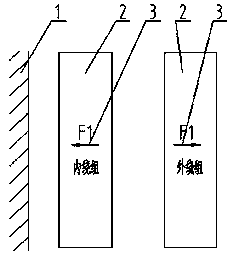

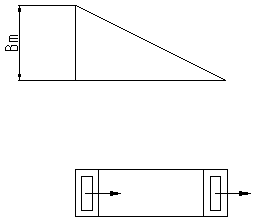

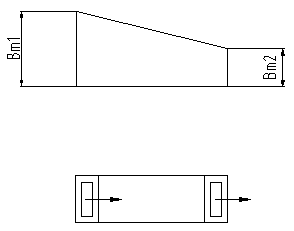

Method used

Image

Examples

example 1

[0097] Example 1. In a certain enterprise, the rectifier transformer ZHSSPZ-6300 / 35, Yd11, the allowable stress of the copper wire ≤ 1600 (kg / cm 2 ), the DC current voltage regulation range is 65%Udn—105%Udn, the high voltage voltage of the transformer is 35KV, and the positive and negative voltage regulation is 35 gears.

[0098] High voltage line current 124A;

[0099] Low voltage phase current 6594A;

[0100] Impedance voltage 7.1%;

[0101] Low-voltage winding 48 cakes (24 double cakes);

[0102] 2.5 turns per pie;

[0103] And the number of winding roots is 4;

[0104] Low-voltage wire gauge: ZB—0.45 2.24×8;

[0105] The high voltage winding is 55cm high;

[0106] The low voltage winding is 56cm high.

[0107] Polyester heat-shrinkable tape is used as the binding tape. According to JB / T4060-1991, the tensile strength of polyester heat-shrinkable tape is 200N / 10mm. When the specification is 25mm, the tensile strength of single-layer heat-shrinkable tape is 500N (51k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com