Foaming material, preparation method thereof and foaming product

A technology of foaming materials and modified materials, which is applied in the field of luminescent materials and their preparation, and foaming products, and can solve problems such as poor impact strength and compressive strength, and limited application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

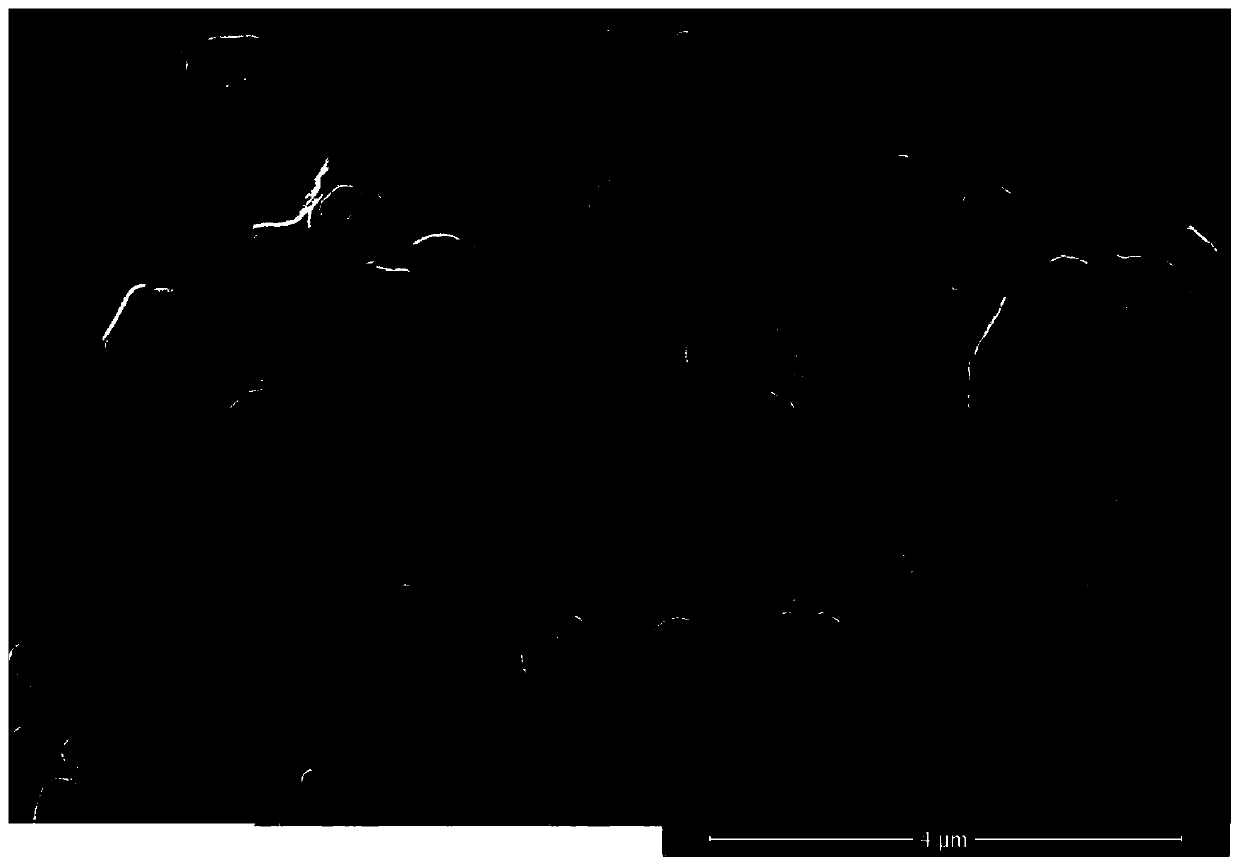

Image

Examples

preparation example Construction

[0046] The present invention also provides the preparation method of above-mentioned foam material, comprises the following steps:

[0047] S101: melting and blending each raw material to obtain a modified material;

[0048] S102: Treat the modified material with a supercritical foaming process to prepare the foamed material.

[0049] In step S101, an extruder can be used for melt blending to obtain the desired modified material; in step S102, supercritical equipment can be used, and further, step S102 includes the following steps: adding the modified material to the autoclave In the medium, quickly fill the foaming agent (such as: carbon dioxide) until the predetermined foaming pressure and temperature are reached, and stand for a period of time until the supercritical gas diffuses into the modified material melt and reaches a saturated state to form a homogeneous system . The polymer / gas homogeneous system is decompressed to atmospheric pressure in a very short time, the s...

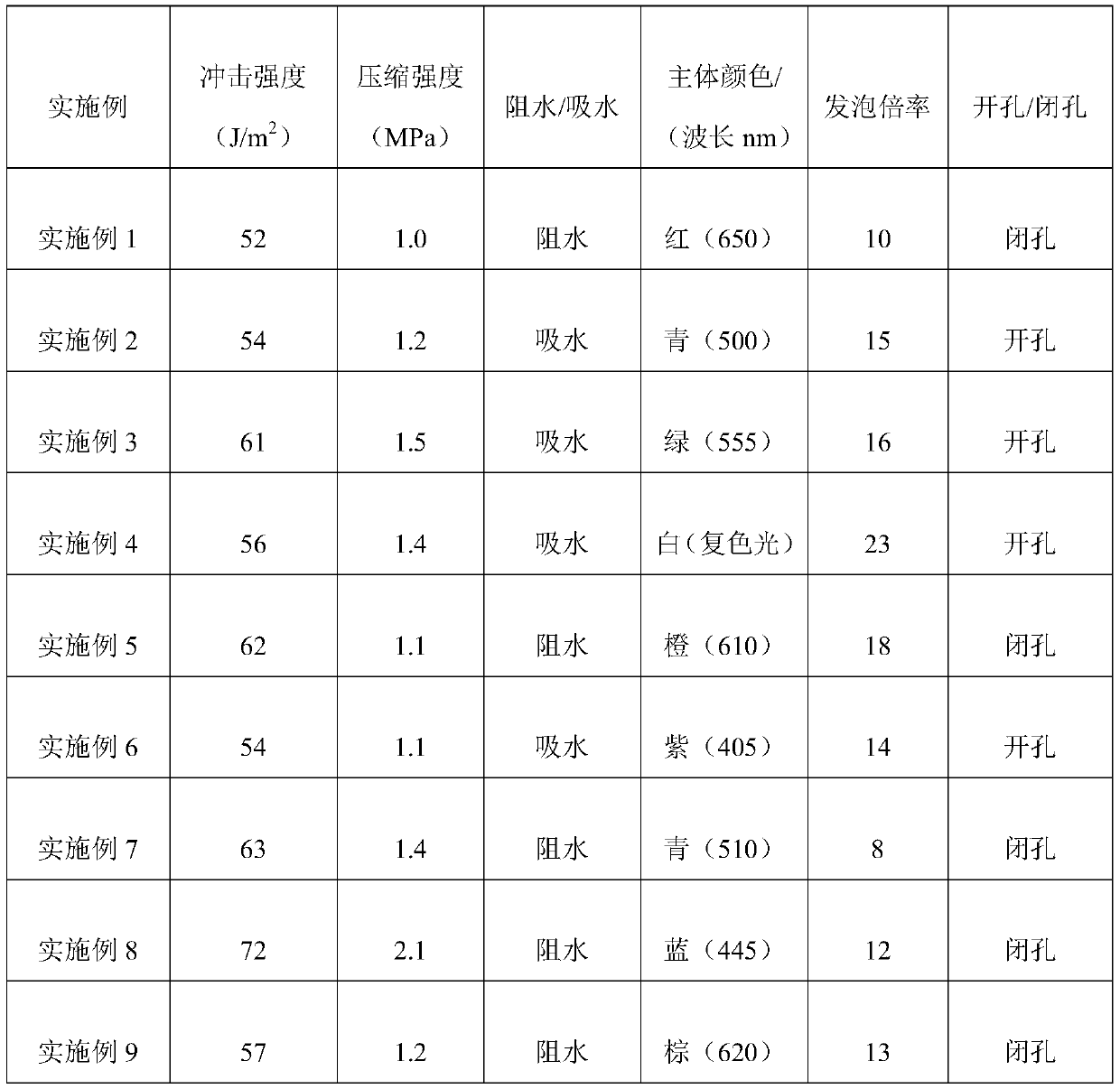

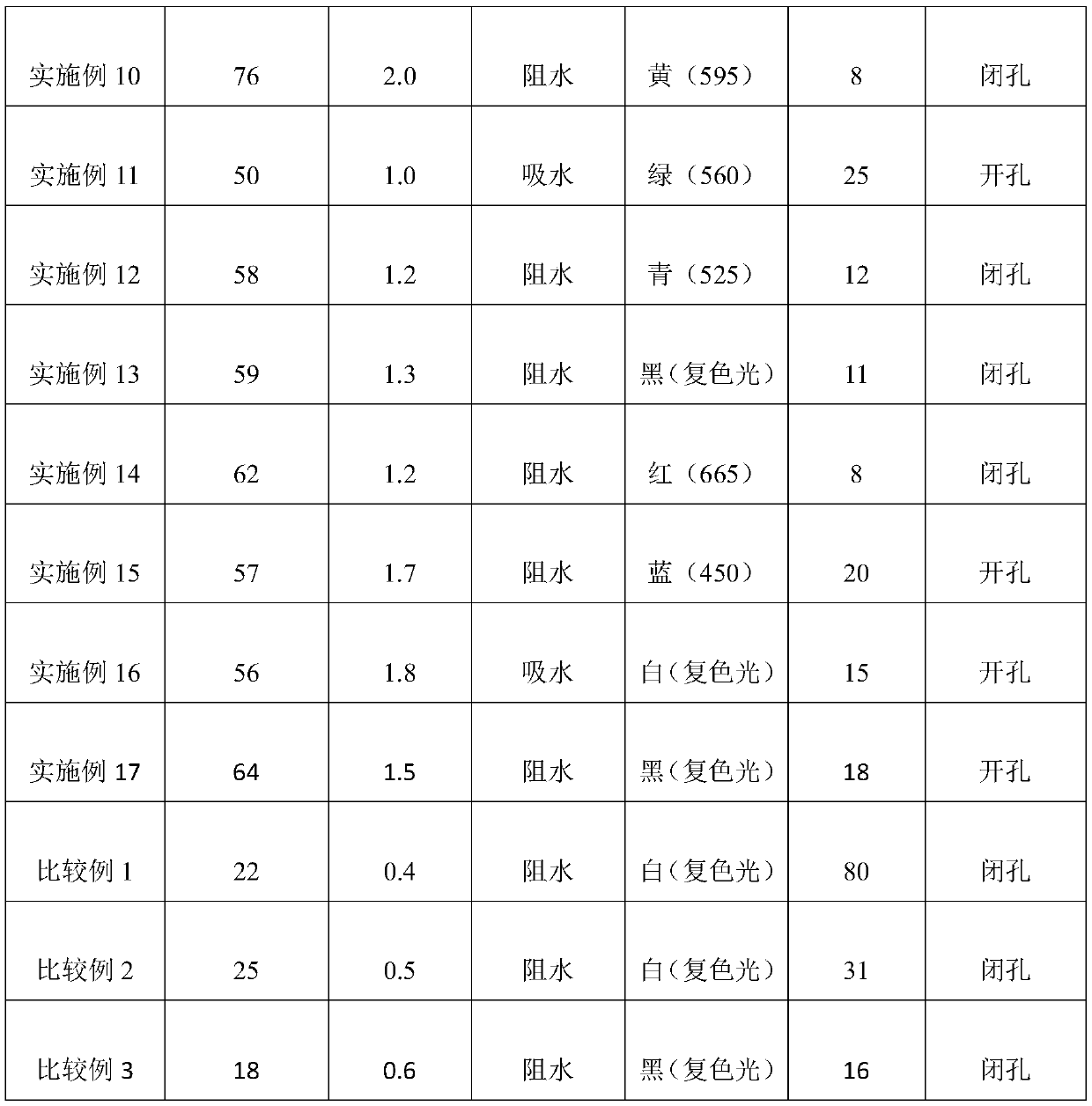

Embodiment 1

[0058] Add 1000g of TPX, 48g of chitin nanocrystals with a particle size of 80nm, 2g of antioxidant 1010, 5g of iron red, 1g of sodium silicate, and 1.5g of calcium stearate emulsion additives into the extruder to blend evenly and extrude out. Adding the modified TPX composition to an autoclave using supercritical CO 2 For foaming, the temperature of the homogeneous system is 225°C, the pressure at saturation is 15MPa, the saturation time is 190min, the pressure release rate is 200MPa / s, and the cooling rate is 5°C / min. The prepared foam material is processed into a board.

Embodiment 2

[0060] Add 1000g of TPX, 30g of nylon 66, 3g of graphene with a particle size of 90nm, 0.1g of antistatic agent, 1g of phthalocyanine pigment, 3g of sodium silicate, and 2g of fatty alcohol additives into the extruder and mix evenly extrude. Adding the modified TPX composition to an autoclave using supercritical CO 2 For foaming, the temperature of the homogeneous system is 235°C, the pressure at saturation is 18MPa, the saturation time is 30min, the pressure release rate is 450MPa / s, and the cooling rate is 6°C / min. The prepared foam material is processed into a hollow container.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com